www.haiwell.com Haiwell PLC - Analog Module Application Case

After setting, select the "parameter download" to download the parameter into the module.

In addition, we can do the following operations through the remote module tool:

Online monitoring the channel value of module, error code.

Upload the module paramater, upgrade the module firmware, then make the module support new features.

It can export the module configuration to save or import and restore the default value.

2.6. Remote IO application example(RS485 mode): The PLC read the 4 communication temperature values of S04AI module

1

Hardware wiring: PLC connects to 485 port of module by shielded twisted pair, A + connects to A +, B- connects to B-, if

the PLC connects to multiple remote IO modules, it needs to use Hand in hand way to connect.

2

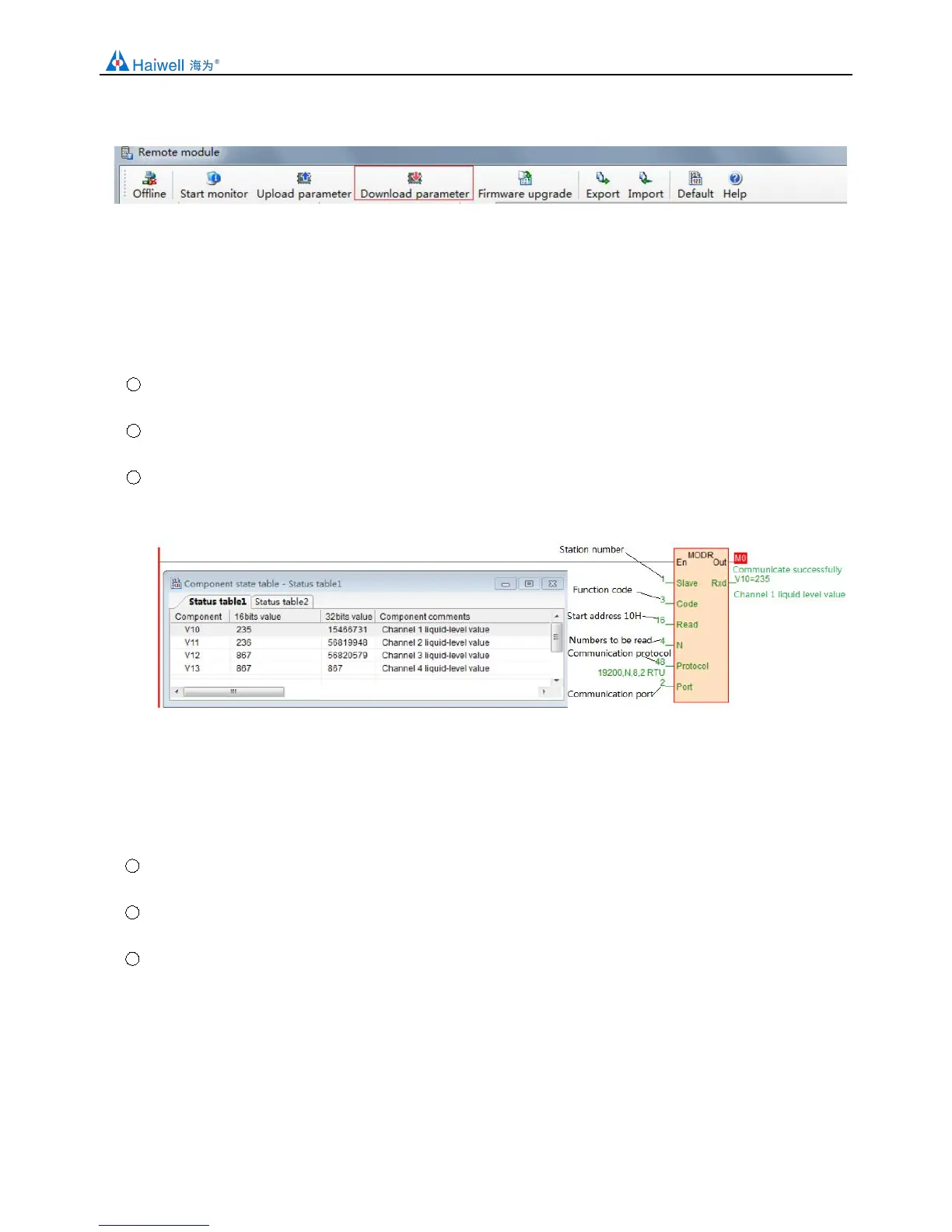

Modbus address: From the above 4-channel analog CR parameter table shows that, the channel 1 ~ 4 input values are

stored in 10H ~ 13H of S04AI module.

3

PLC program: Host PLC wants to read the 4-channel liquid level values of remote IO module S04AI, 0 ~ 1000 indicates

that 0 ~ 1.0m. In this example, S04AI communication is the default parameter: Station number address is 1, baud rate is

19200, data format is N 8 2 RTU. The program of PLC reads the 4-channel liquid level values is as follows:

The host PLC reads the 4-channel liquid level values of S04AI by Modbus read instruction MODR, the start address is

10H (hexadecimal), that is, the decimal value is 16. When the communication is successful, M0 is ON, the liquid level

values which are read back will be stored in V0-3, V0=235, indicating that the actual temperature of the first channel is

0.235m, the same as V3=867, indicating that the actual temperature of the fourth channel is 0.867m.

2.7. Remote IO application example (RS485 mode): The PLC writes the 8-channel output values of S08AO module

1

Hardware wiring: PLC connects to 485 port of module by shielded twisted pair, A + connects to A +, B- connects to B-, if

the PLC connects to multiple remote IO modules, it needs to use Hand in hand way to connect.

2

Modbus address: From the above 8-channel analog CR parameter table shows that, the channel 1 ~ 8 output values of

S08AO module are stored in address 10H~17H .

3

PLC program: Host PLC wants to write the 8-channel analog output values of remote IO module S08AO. In this example,

S08AO communication parameters: Station number address is 2 (set by DIP switch), baud rate 19200, data format N 8 2

RTU. The program of writing 8-channel analog output values is as follows:

Loading...

Loading...