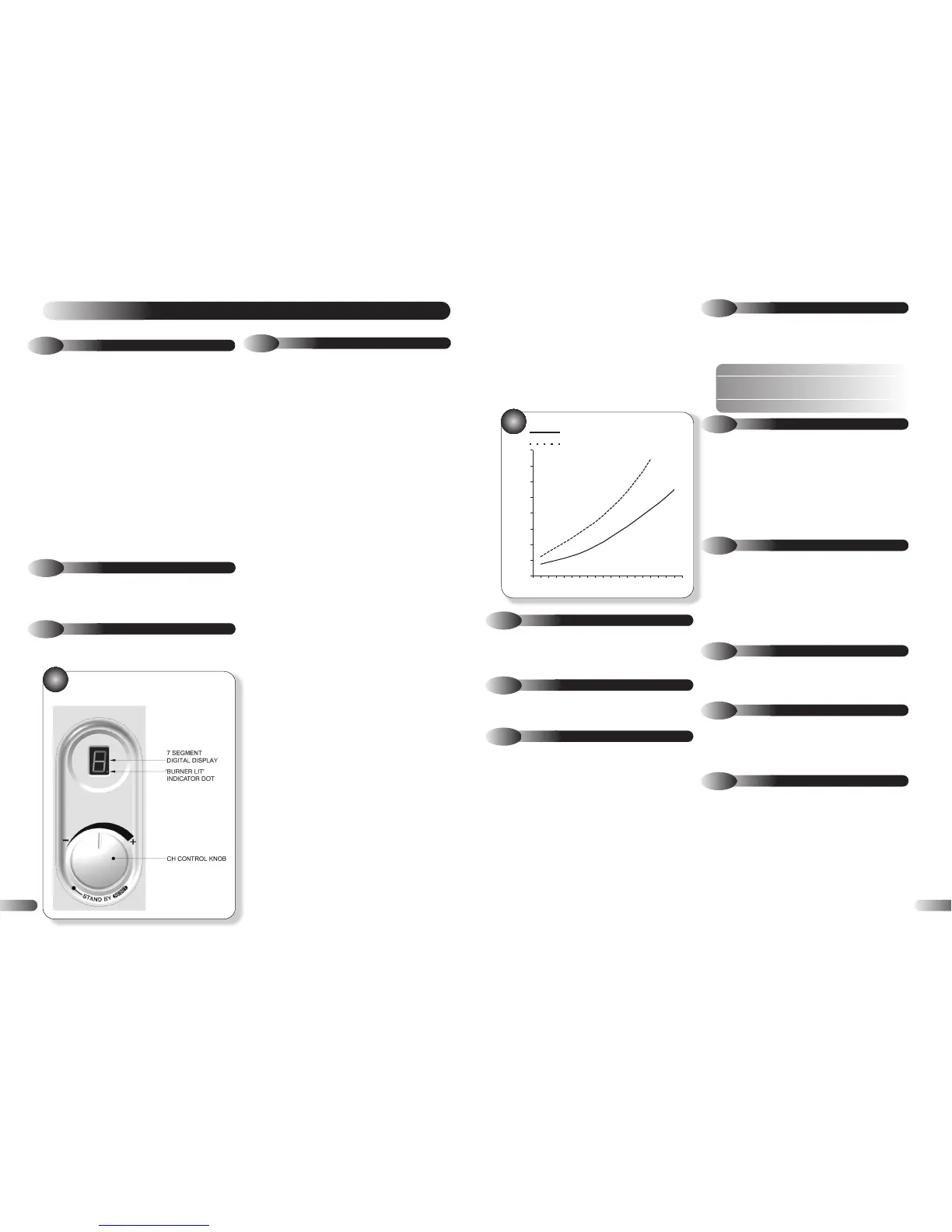

Flow Rate ltr/min

Pressure Drop (m H

2

0)

VBX 30

VBX 18

6

A draining tap must be provided at the lowest point of the system,

which will allow the entire system and hot water system to be drained.

Draining taps shall be to the current issue of BS 2879.

3.8

DRAINING TAP

A safety valve need not be fitted to an open vented system. (See

3.16 for sealed systems)

3.8

SAFETY VALVE OPEN VENTED SYSTEM

3.10

PUMP

The pump should be fitted on the flow pipe from the boiler and

have isolating valves each side.

A variable duty pump should be set to give a temperature

difference of no greater than 20°C between the flow and return,

with the thermostat set at “MAX”, which is approximately 80° to

give a flow rate as shown in table 1.

See figure 6 for pressure loss of the boiler.

High resistance microbore systems may require a higher duty pump.

3.11

FLOW RATE

If it is necessary to alter the flow rate, the system can be fitted

with a lockable balancing valve in the main flow or return pipes

shown as valve “A” in figure 7. The flow rate through the boiler

must not be allowed to fall below that given in table 1.

Table 1. Flow Rate

MINIMUM FLOW RATE

200 l/h

This is equal to 20°C differential at minimum heat input.

3.12

WATER TREATMENT

WATER TREATMENT, CLEANSING AND FLUSHING THE

HEATING SYSTEM

NOTE:

British Standard BS7593: 1992 stresses the importance

of cleansing and flushing of the system to ensure it continues to

run efficiently with the minimum of maintenance necessary.

Halstead Boilers fully support this professional approach and

recommend that the system is cleansed with an effective chemical

cleanser and protected long term with a suitable inhibitor. Such

products are available from Fernox and Sentinal.

3.13

OPEN VENTED WATER SYSTEM

The boiler must be supplied from an unrestricted water supply

taken from a feed and expansion cistern situated at a maximum

height of 27 metres (90ft) above the boiler.

The cold feed must be 15mm minimum size.

The vent must rise continuously and be unrestricted.

It is important that the relative positions of the pump, cold feed

and open vent are as shown in figure 8.

3.14

DOMESTIC HOT WATER CYLINDER

SINGLE FEED INDIRECT CYLINDERS ARE NOT SUITABLE

The domestic hot water cylinder must be of the double feed fully

indirect coil type.

3.15

SEALED WATER SYSTEMS

The installation must comply with the appropriate requirements of

the current issue of BS4814, BS5449, BS6759, BS6798 and

BS7074 Part 1 and 2.

See figure 7 for a suggested layout.

3.16

SAFETY VALVE SEALED SYSTEM

A safety valve must be fitted to a sealed system.

It shall be preset, non-adjustable with a lift pressure of 3 bar,

incorporating seating of a resilient material, a test device and a

connection for drain.

The drain from the safety valve must be routed outside the

building, must not discharge above an entrance or window or

any type of public access area, be clear of any electrical fittings

and positioned so that any discharge can be seen.

26

FAULT FINDING

8

8.1

GENERAL

Before looking for a fault condition, check that:

● The mains electrical supply is turned on.

● The room or cylinder/tank thermostat (where fitted) are calling

for heat.

● The gas service cock is open.

● The system is at design pressure.

Before attempting any electrical fault finding, always conduct the

preliminary electrical system checks as described in the

Instructions for the British Gas Multimeter, or other similar

instrument.

On completion of any service or fault finding operation involving

making or breaking electrical connections, always check for

EARTH CONTINUITY, POLARITY and RESISTANCE TO EARTH.

Detailed procedures for replacing faulty components are

described in section 9 (Parts Replacement).

For further information contact: Halstead Boilers Ltd. Service Help

line: 01926 834834

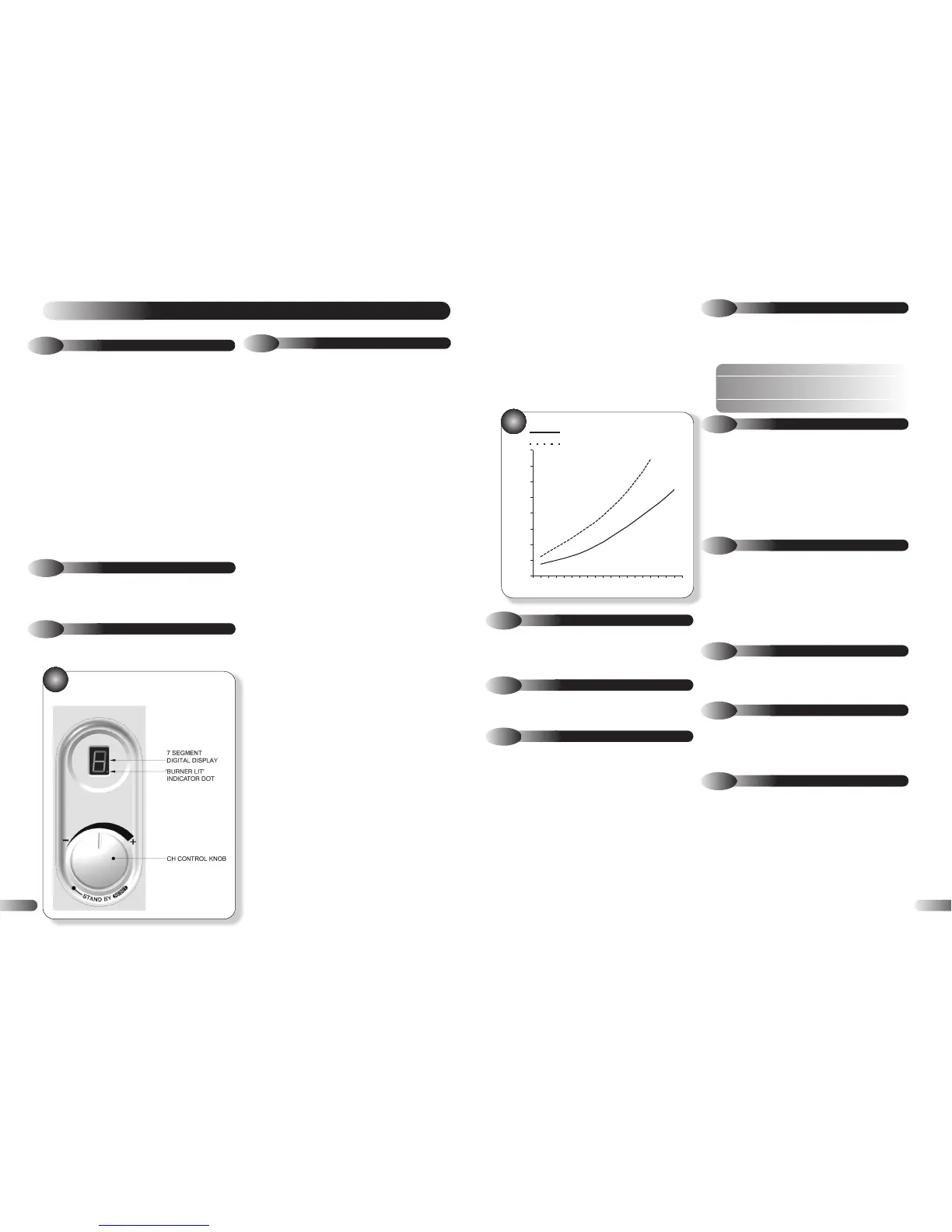

8.2

DIAGNOSTIC LED INDICATORS

FASCIA PANEL - Refer to Figure 32.

The LED shows code '3' in a lockout condition.

For fault finding refer to the diagnostic chart shown below.

8.3

FAULT FINDING CODES

In the event of the appliance failing to light, refer to the

Diagnostics Chart.

FACIA PANEL

32

Upon a demand for Central Heating, (closure of the time switch

and room thermostat, where fitted), the controls should carry out a

set of start up checks, followed by an ignition sequence. Refer to

Section 5.2.

If the control has powered up correctly but does not respond to a

CH demand. Remove plug cover and check voltage between L3

(orange) and N (blue). If 0 V ac, check external programmer /

room thermostat. If 230 V ac, check control for lockout or

blocking codes, (refer to section 8.3), check operation of the

external pump.

Note: Whenever a CH demand is removed, an anti cycle mode is

initiated which prevents the appliance from firing in CH mode for

5 minutes. Ensure that the control is not in this mode by removing

power from the control and restoring it after a delay of 10

seconds.

If the Switch Live input is OK and no lockout or blocking code

exists and the control is not in anti cycle mode, then replace PCB.

8.4

CENTRAL HEATING FAULT FINDING

Loading...

Loading...