3e

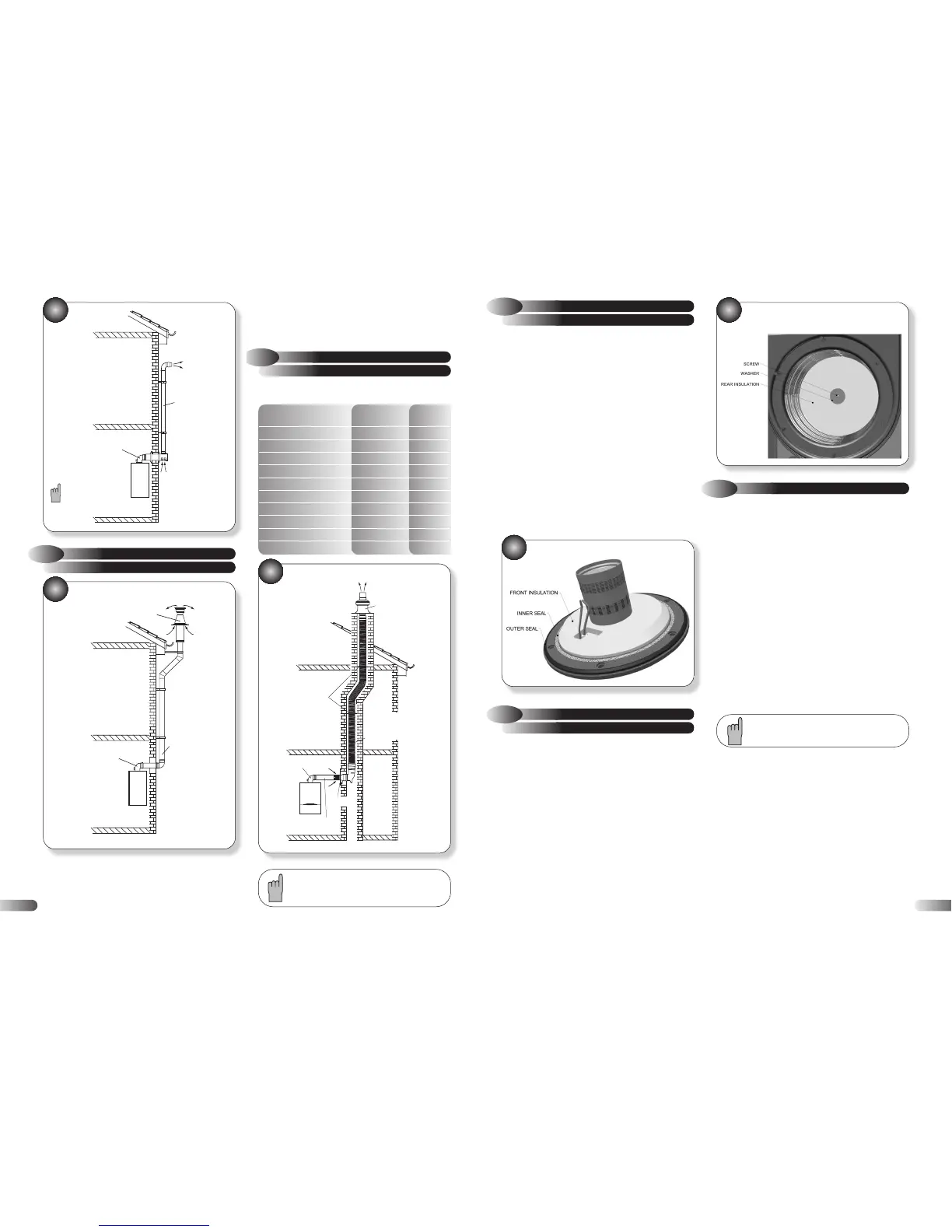

Suitable for installations if the appliance can't be repositioned

and where other horizontal flue options may cause some nuisance

to neighbours or buildings. The flue kit contains some additional

45° elbows and extension ducts as well as a special wall bracket

to pass the guttering (see Figure 3e). The concentric flue will be

2.6

KIT E CHIMNEY FLUE LINER KIT

Maximum flue resistance permitted for an opened flued system = 100 Pa.

Minimum flue resistance permitted for an opened flued system = 38 Pa.

Flue Component Flue Resistance Part

(Pa) Number

Air inlet Assembly (required) 9 -

60/80 Adaptor (required) 12 -

Ter minal (required) 9 -

91.5° Elbow (80) (required) 8 -

80 diameter Corrugated (required) 2/metre -

80 mm diameter straight duct 2/metre -

Horizontal Flue Adaptor 15 956086

Vertical Flue Adaptor 0 956087

93° Elbow (60/100) 15 956091

45° Elbow (60/100) 7 956090

3d

routed vertically alongside the outside wall to above the roofline.

Special seals are required to prevent rainwater penetrating the

pipe joints.

For installation details refer to the flue kit instructions.

31

FRONT INSULATION

9.6

COMBUSTION CHAMBER

The design of the appliance is such that the combustion chamber

insulation should not require replacement unless mechanically

damaged. It is recommended that to prevent dust, the insulation

be dampened prior to removal, and that a protective mask is

worn when changing or handling the insulation material.

Refer to Figure 43

a)

Ensure supply voltage is isolated, and that the gas supply is

isolated.

b) Remove the gas control valve, fan & burner assembly; refer to

section 6.2.

c) Remove the electrodes; refer to section 9.1.

d) Remove the burner: refer to section 9.5.

e) Replace the combustion chamber front insulation.

f) Re-assemble the burner and electrodes, using new gaskets.

g) Check the position of the electrodes: refer to section 6.4.

h) Re-assemble in reverse order; ensure that all joints and seals

are correctly re-fitted.

43

COMBUSTION CHAMBER FRONT

INSULATION

INSULATION

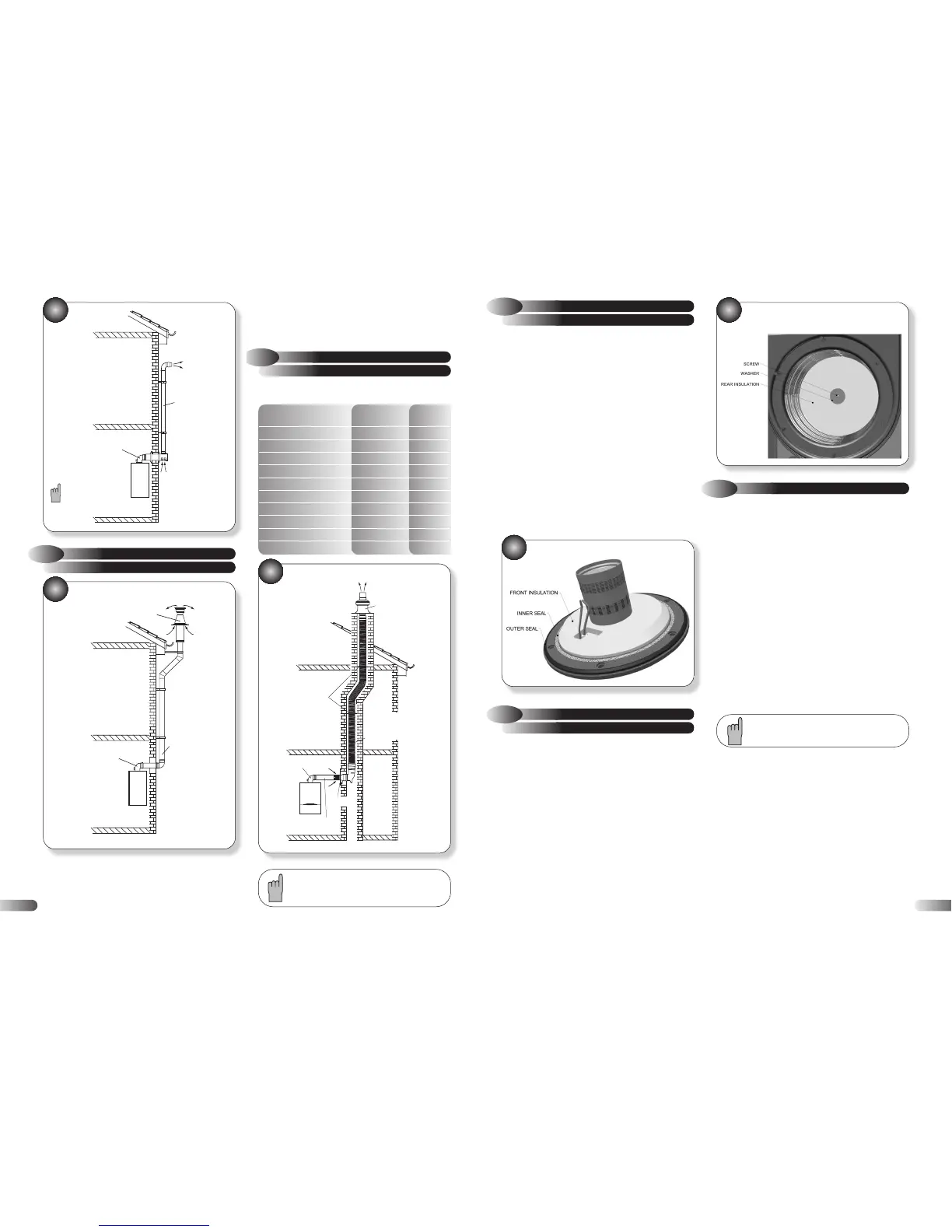

9.7

COMBUSTION CHAMBER REAR

Refer to Figure 44

a)

Ensure supply voltage is isolated, and that the gas supply is

isolated.

b) Remove the gas control valve, fan & burner assembly; refer to

section 6.2.

c) Use an Allen key to undo the central screw holding the rear

insulation in place.

d) Remove old insulation and fit replacement, ensuring locating

washer is in front.

e) Re-assemble in reverse order; ensure that all joints and seals

are correctly re-fitted.

44

COMBUSTION CHAMBER REAR

INSULATION

9.8

HEAT EXCHANGER

Refer to Figures 14, & 45

a)

Ensure supply voltage is isolated, and that the gas supply is

isolated.

b) Remove the gas control valve, fan & burner assembly; refer to

section 6.2.

c) Disconnect the electrical lead to the flue sensor, remove both

flow and return sensors noting which goes where.

d) Drain down central heating system.

e) Disconnect the flue system from the appliance, 4 screws, and

lift up to disengage the flue from the flue hood; refer to Figure 14.

f) Remove the retaining clip from the heat exchanger flow outlet;

refer to Figure 45.

g) Gently pull up (or down, depending on installation) to

disengage the flow pipe from the heat exchanger.

h) Remove the retaining clip from the heat exchanger return

inlet.

i) Gently pull up (or down, depending on installation) to

disengage the return pipe from the heat exchanger.

It may be necessary to cut both flow and return

pipes to disengage them from the heat exchanger.

j) Disconnect the condensate drainpipe from the condensate

drainpipe sump adaptor; refer to section 9.18.

k) Unscrew the three nuts holding the heat exchanger to the

back panel; refer to Figure 45.

l) Remove the heat exchanger.

m) Disconnect the condensate drainpipe sump adaptor from the

heat exchanger.

n) Remove the flue hood from the heat exchanger, two screws,

and fit the flue hood onto the new heat exchanger, Check

integrity of the flue hood seals and replace as necessary. Remove

the manual air vent and vent tube from the heat exchanger and fit

onto to new heat exchanger; refer to Figure 45.

o) Fit the condensate drainpipe sump adaptor to the heat

exchanger and flue hood.

p) Re-assemble in reverse order; check integrity of the flow and

Loading...

Loading...