5

All desiccant shipped loose must be added to the

dryer chambers before the dryer is put into service

Refer to TABLE 1, DESICCANT REQUIREMENTS for

desiccant type and quantity per tower.

TO ADD DESICCANT

WARNING — The following procedure provides in-

structions for adding the initial desiccant to the tow-

ers. If replacing desiccant, refer to the “Procedure

for Desiccant Charge Replacement” in Section 7.0.

1. Verify pressure gauges of both towers indicate

0 psig. If not, depressurize the towers according to

the shutdown instructions in Section 6.

2. Remove the pipe plug or fill port flange cover (where

applicable) from the desiccant fill port at the top of

each tower. Refer to Figure 3 for the fill port loca-

tion.

CAUTION – Pouring desiccant creates a fine dust;

safety goggles, gloves and a dust mask should be

worn by personnel installing desiccant. Refer to the

Material Safety Data Sheet that accompanies desic-

cant shipped loose for more complete information.

CAUTION – Do not tamp the desiccant in the towers.

Tamping damages desiccant and causes dusting.

3. Refer to Table 1 for desiccant quantity per tower.

When using Table 1 you will find the desiccant quan-

tities listed in layers. Each layer will vary in depth

due to the type, quantity and purpose of the desic-

cant. Layer 1 must be installed first at the bottom of

the vessel followed by layer number 2 etc., until the

complete charge of desiccant has been installed.

4. Utilizing an appropriate sized funnel, fill each desic-

cant tower as follows:

a. Install the required quantity of tabular support or

activated alumina in layer 1 of each tower.

b. Level layer 1 and each subsequent layer of desic-

cant as added to each chamber.

c. Finish filling each tower with desiccant until all

desiccant has been installed. LIGHT tapping

on the tower sides with a soft-face mallet should

yield additional free space to allow installation of

all desiccant required. DO NOT TAMP OR RAM

DESICCANT.

5. Clean the fill port closure. Replace the fill plug using

Teflon tape or another pipe thread sealant suitable

for compressed air service. Reinstall fill port flange

cover (where applicable) in each desiccant tower.

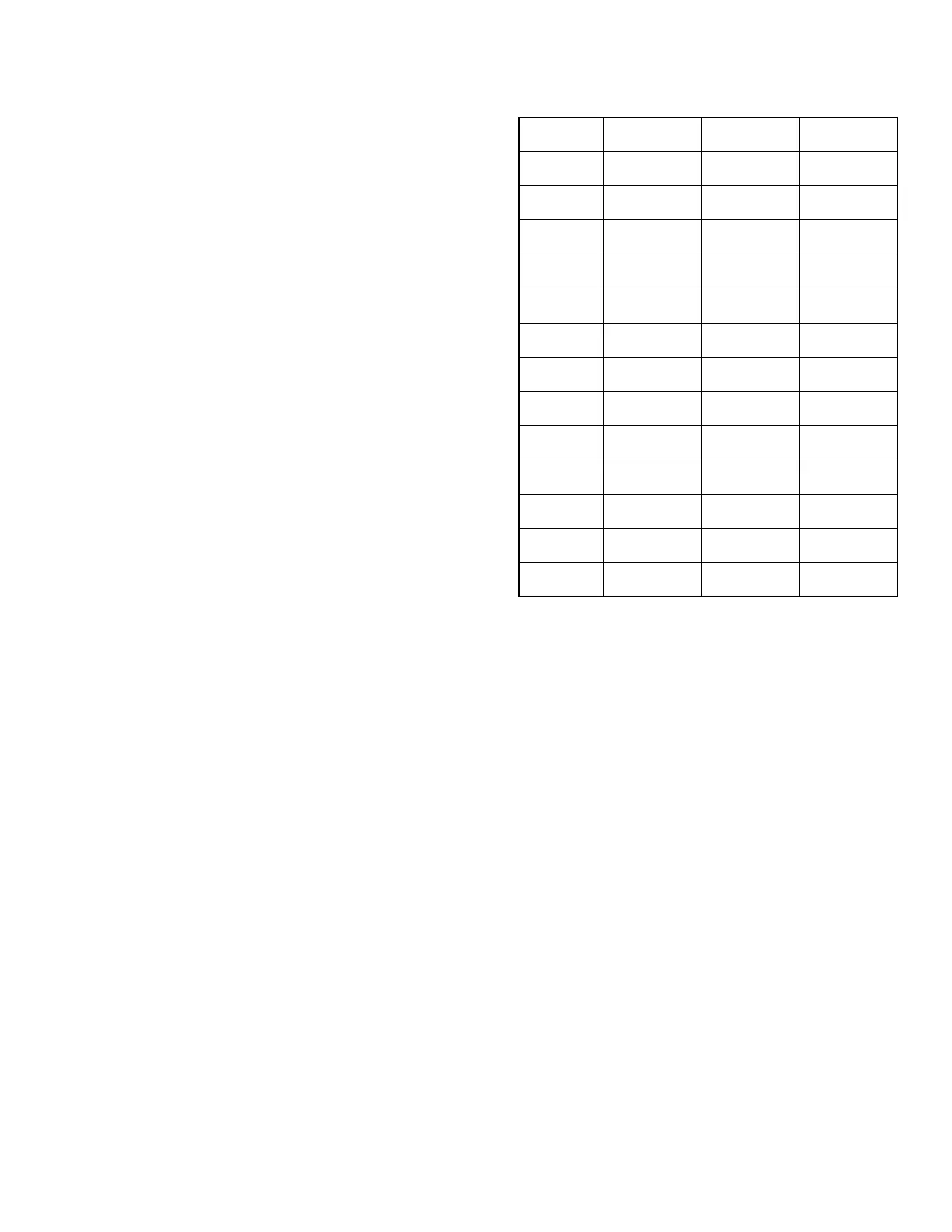

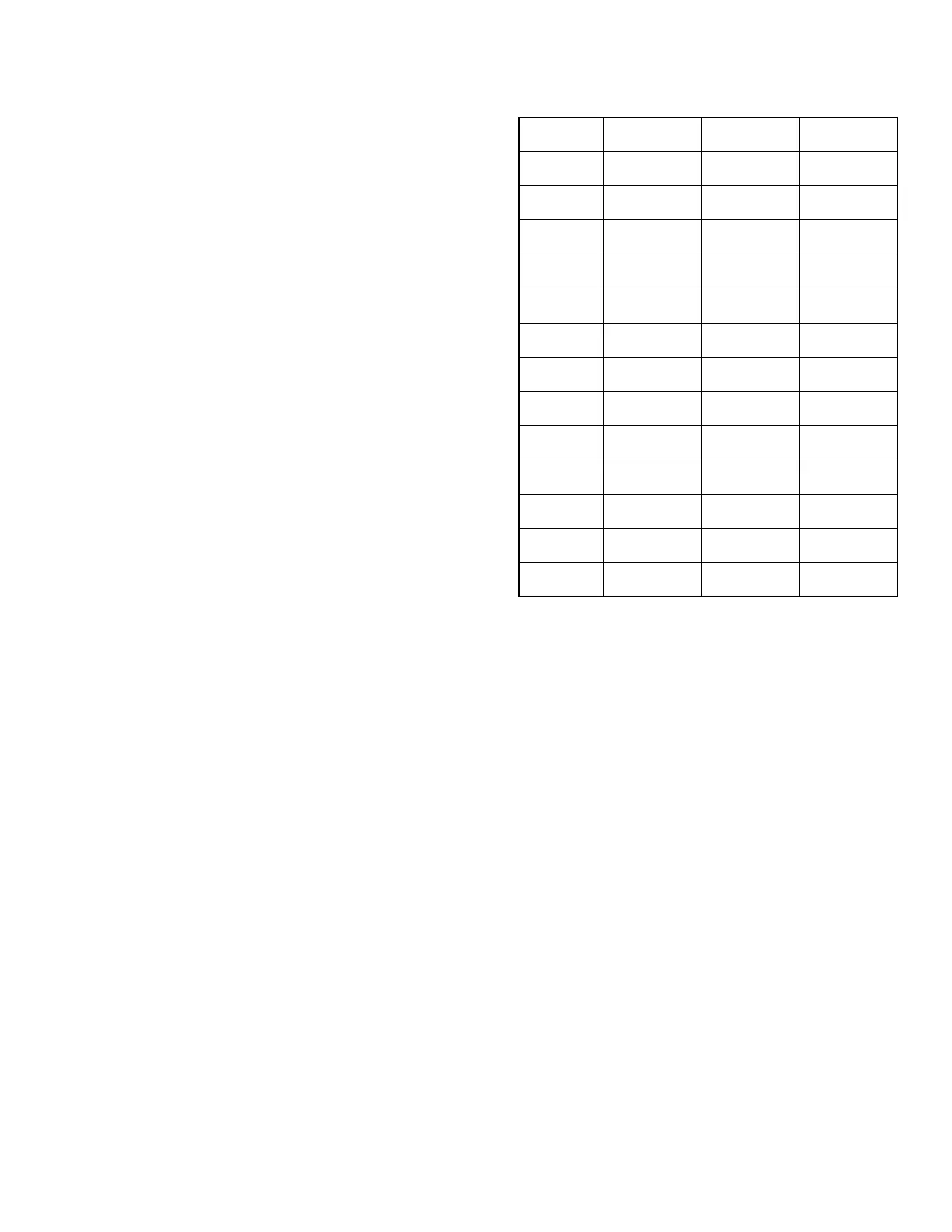

TABLE 1

DESICCANT REQUIREMENTS

(Quantity per Tower)

Layer

Model

1 2 3

500

354#

1/8” bead AA

— —

600

453#

1/8” bead AA*

— —

750

590#

1/8” bead AA

— —

900

590#

1/8” bead AA*

— —

1050

710#

1/8” bead AA

— —

1300

48#

1/4” bead AA*

876#

1/8” bead AA*

—

1500

92#

1/4” bead AA*

1167#

1/8” bead AA*

—

1800

92#

1/4” bead AA*

1167#

1/8” bead AA*

—

2200

161#

1/4” bead AA

1706#

1/8” bead AA*

—

2600

161#

1/4” bead AA*

1706#

1/8” bead AA*

—

3200

258#

1/4” bead AA*

2119#

1/8” bead AA*

—

3600

258#

1/4” bead AA*

2353#

1/8” bead AA*

—

4300

719#

1/2” bead TS**

146#

1/4” bead AA*

2679#

1/8” bead AA*

* AA = Activated Alumina

** TS = Tabular Support

Loading...

Loading...