HA4AM ELECTRIC MOTOR

COMPENSATED REGULATOR

OPERATION

The regulator pressure setting is altered as the motor

receives a signal from a suitable temperature

controller. The motor responds to maintain the balance

in the electrical circuit. The rotation of the motor is

transmitted through a cam, valve stem, and range

spring to the top of the control module diaphragm. An

increase in temperature decreases the range spring

force on top of the control module diaphragm. This

decrease in force on the diaphragm allows inlet

pressure to pass through the control module to enter

the space on top of the piston which forces the main

valve seat open to reduce the evaporator pressure. A

decrease in temperature causes an increase in the

range spring force. This restricts the flow of inlet

pressure to the piston causing a reduction in the

opening of the main valve seat, reducing regulator flow

by raising the pressure setting.

APPLICATIONS

This motor compensated regulator is popular for fruit

storage, precision air temperature control, and liquid

chiller control.

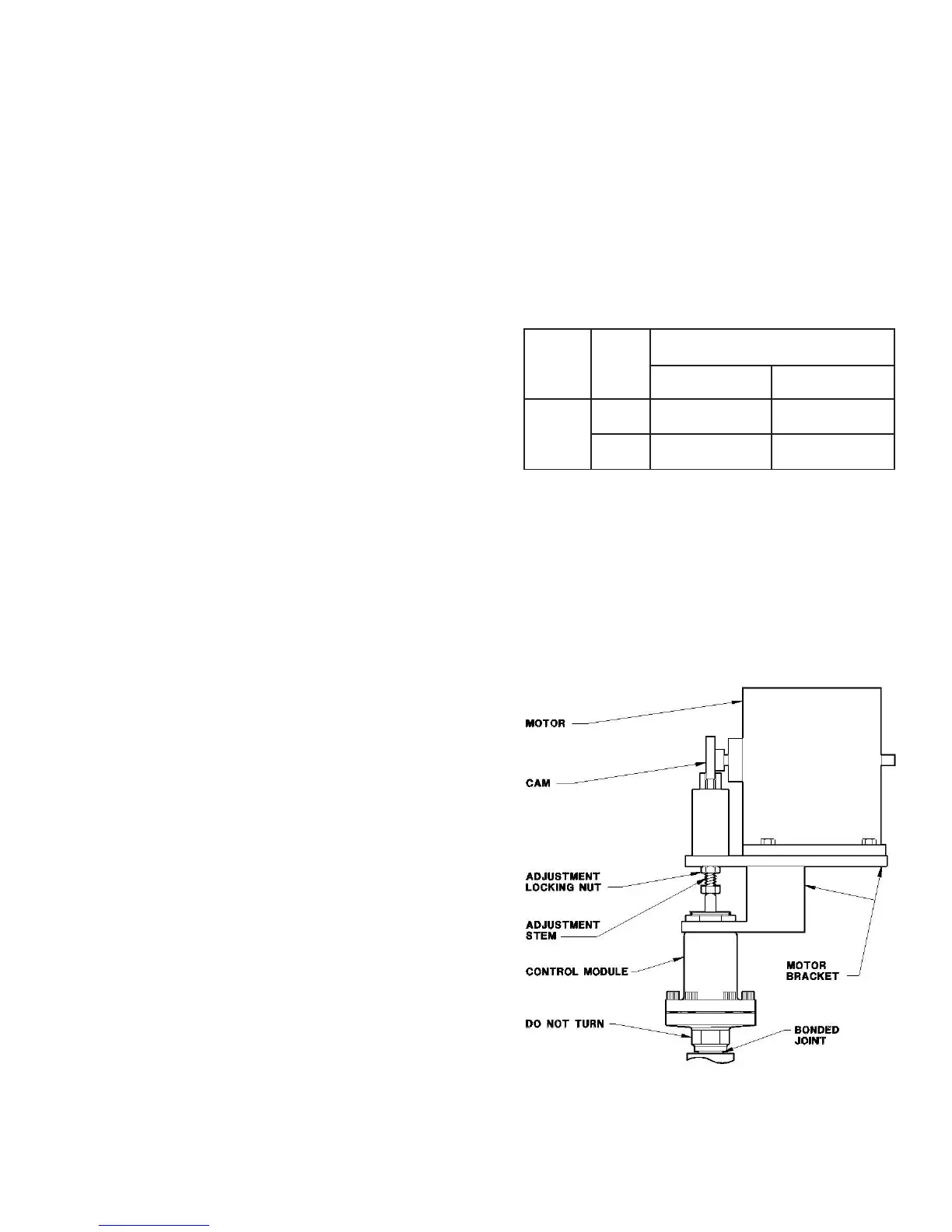

ADJUSTMENT

Adjust the temperature controller as specified by the

manufacturer. Fully open the regulator manually by

turning in (clockwise) the manual-opening stem to cool

the product or room. Once the temperature at the

sensing device is approximately as desired, adjust the

controller output so that the cam is rotated to the

center position. Put regulator back in automatic

operation by turning the manual-opening stem out

(counterclockwise). Loosen the adjustment locking nut.

See the diagram to the right. Turn the adjustment stem

clockwise to raise the inlet pressure setting or

counterclockwise to lower the inlet pressure setting.

When the desired refrigerant pressure setting is

achieved, tighten the adjustment locking nut. A final

adjustment should be made after the system has

operated for a period of time.

Using a potentiometer slide wire type of controller

(typically 135 ohm), depending on product heat load, a

deviation from desired temperature of about +2F to +5F

(+1.1°C to +2.8°C) is normal to rotate the regulator cam

for maximum load satisfaction. As the load is reduced

or as the temperature becomes lower, the cam rotates

to create a higher evaporator pressure just adequate to

balance the load and maintain the desired temperature,

usually with ±1°F (0.5°C). Other controllers are available

to operate the motor/cam rotation.

The basic Electric Motor Compensated Regulator

consists of a nonremovable control module with a

motor bracket and cam. The control module is available

in either Range A, 0 to 150 psig (0 to +10 bar); or Range

V, 20" to 130 psig (–0.67 to +9 bar). The motor bracket

comes mounted on the control module and is suitable

for use with either PENN (standard) or HONEYWELL

motors. Two cams are available: Low Rise (standard)

and High Rise. The table below indicates the pressure

change possible for each cam and motor combination.

The PENN motor (standard) has 270° of rotation travel

and the HONEYWELL motor has 160° of rotation travel.

Motors are available for either 135 ohm or 4–20 mA

control signal input and require 24 VAC power input.

Electric proportional thermostat controllers (135 ohm

output), electronic PID controllers (4–20 mA output)

with sensor, and 24V transformers are available

accessories.

Loading...

Loading...