12

Maintenance

In order to derive full benefit from the sprayer for many years the

following few but important rules should be kept:

Cleaning the sprayer - see Spray Technique book.

Filters

Clean filters ensure :

• Sprayer components such

as valves, diaphragms

and operating unit are not

hindered or damaged

during operation.

• Nozzle blockages do not

occur whilst spraying.

• Long life of pump. A

blocked suction filter will

result in pump cavitation.

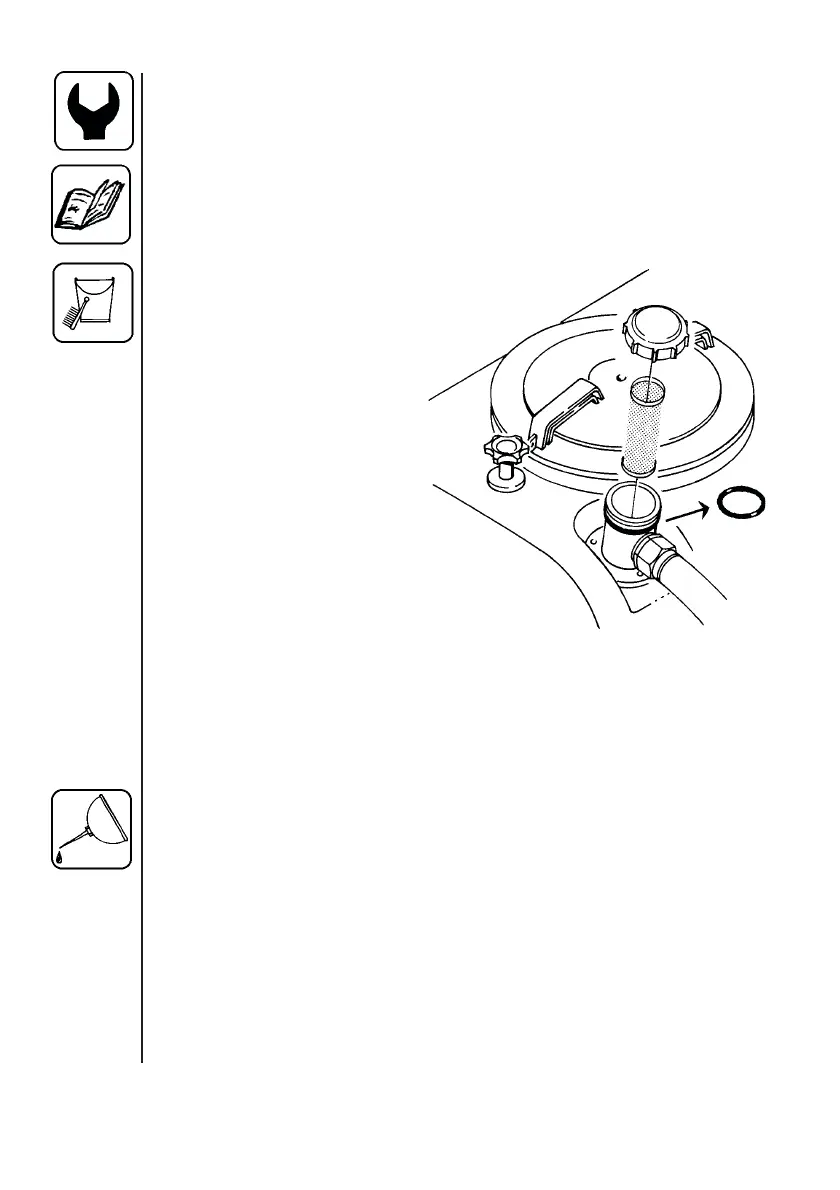

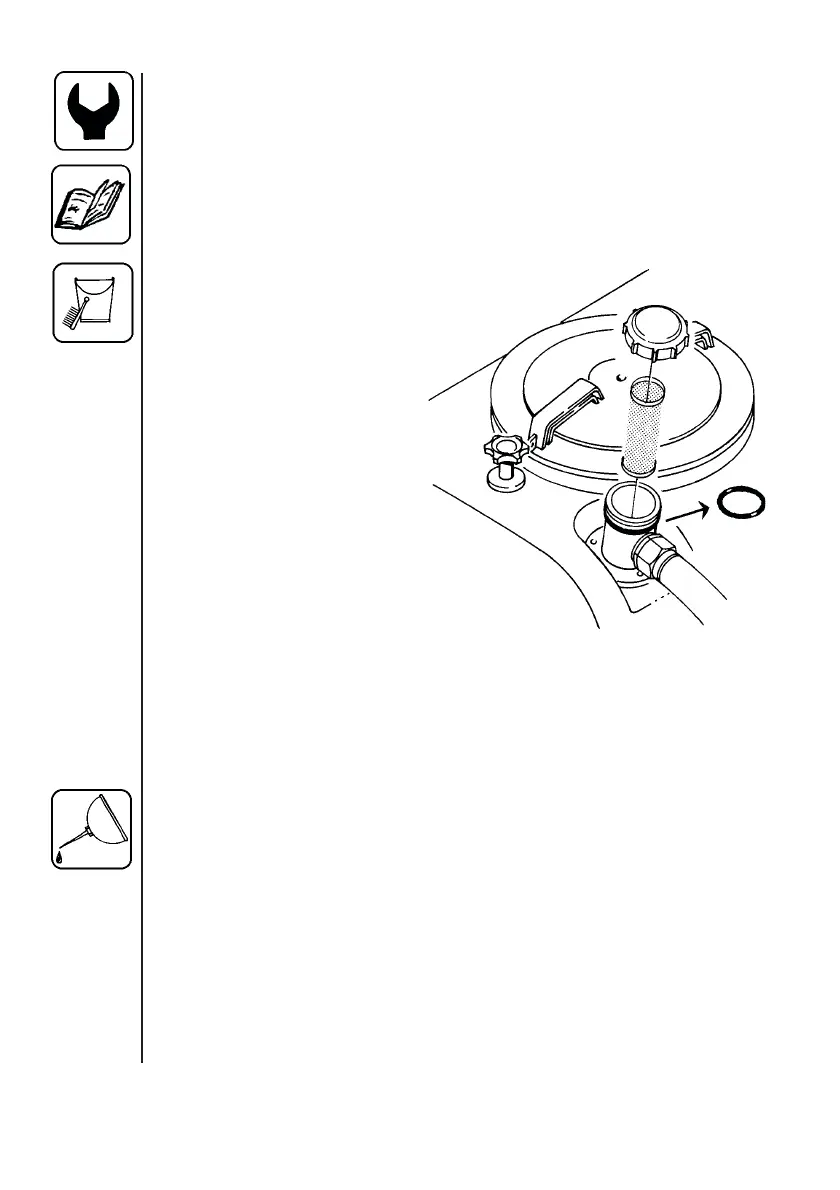

The main filter protecting

sprayer components is the

suction filter at the top of the

tank. Check it regularly.

Ensure the O-ring on filter housing is in good condition and lubricated.

The operating unit has an in-built pressure filter. See section on Drain

valve operation.

Lubrication

Recommended lubrication is shown in following tables. Use ball

bearing grease (lithium grease No.2)

NOTE: If the sprayers are cleaned with a high pressure cleaner or it

has been used to spray fertilizer, we recommend lubrication of the

entire machine.

Loading...

Loading...