22

For face connections, a little me-

chanical leverage may be used.

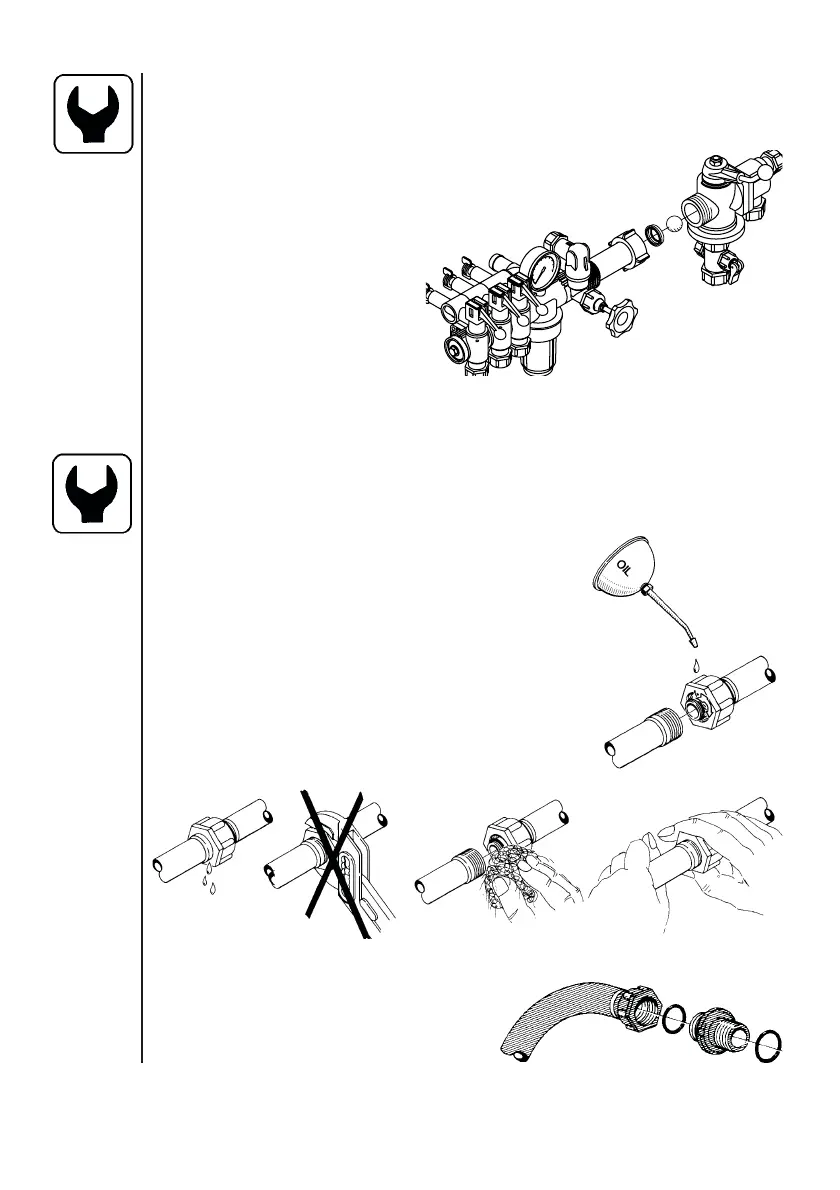

Changing of ball seat in operating unit

If problems with on/off valve occurs (dripping nozzles when on/off

valve is closed), the ball and ball seat should be checked.

Remove the 2 bolts fixing the

on/off-pressure valve unit to

the bracket, unscrew the

union nut A and pull the on/

off-pressure valve away from

the distribution valves.

Check the ball for sharp

edges and scratches and

check the ball seat for

cracks and wear - replace if necesary.

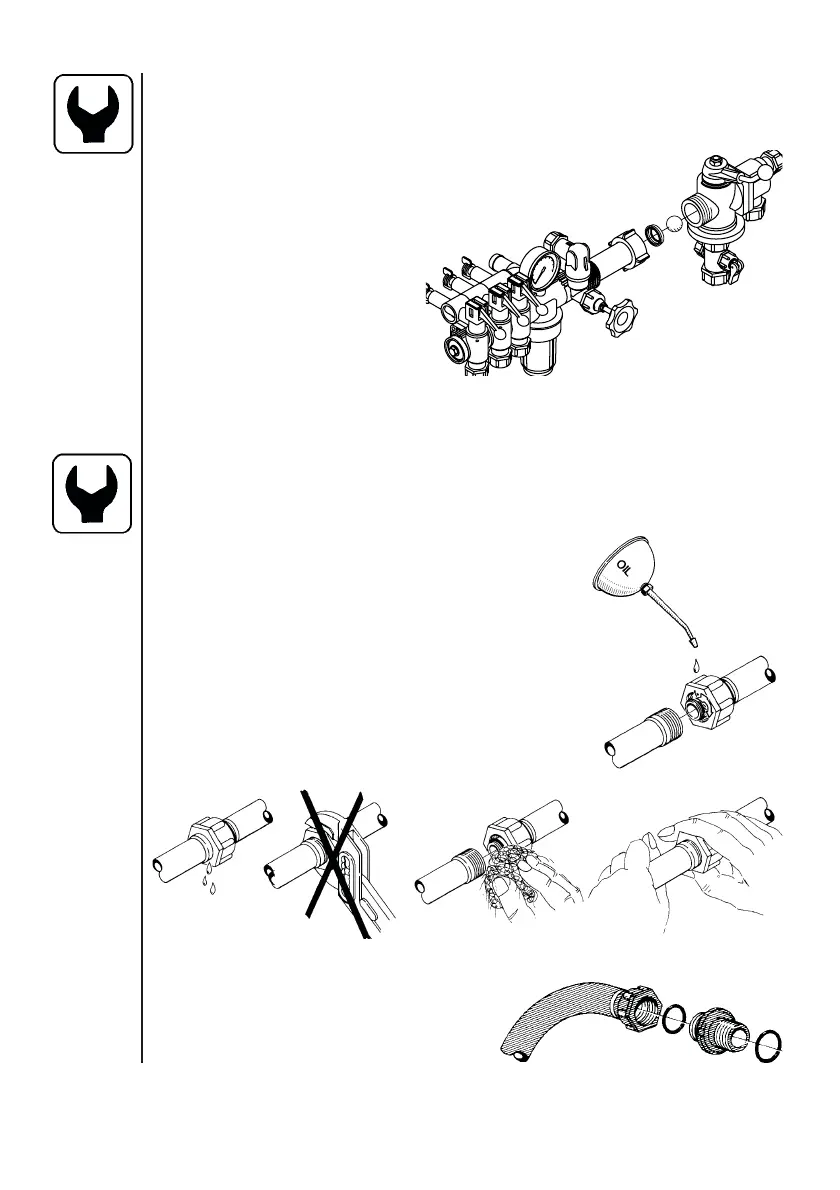

Nozzle tubes and fittings

Poor seals are usually caused by;

• missing O-rings or gaskets

• damaged or incorrectly seated O-rings

• dry or deformed O-rings or gaskets

• foreign bodies

Therefore, in case of leaks: DO NOT overtighten.

Disassemble, check condition and position of O-

ring or gasket, clean lubricate and reassemble.

For radial connections only hand tighten them.

Lubricate ALL THE WAY ROUND before fitting.

A

Loading...

Loading...