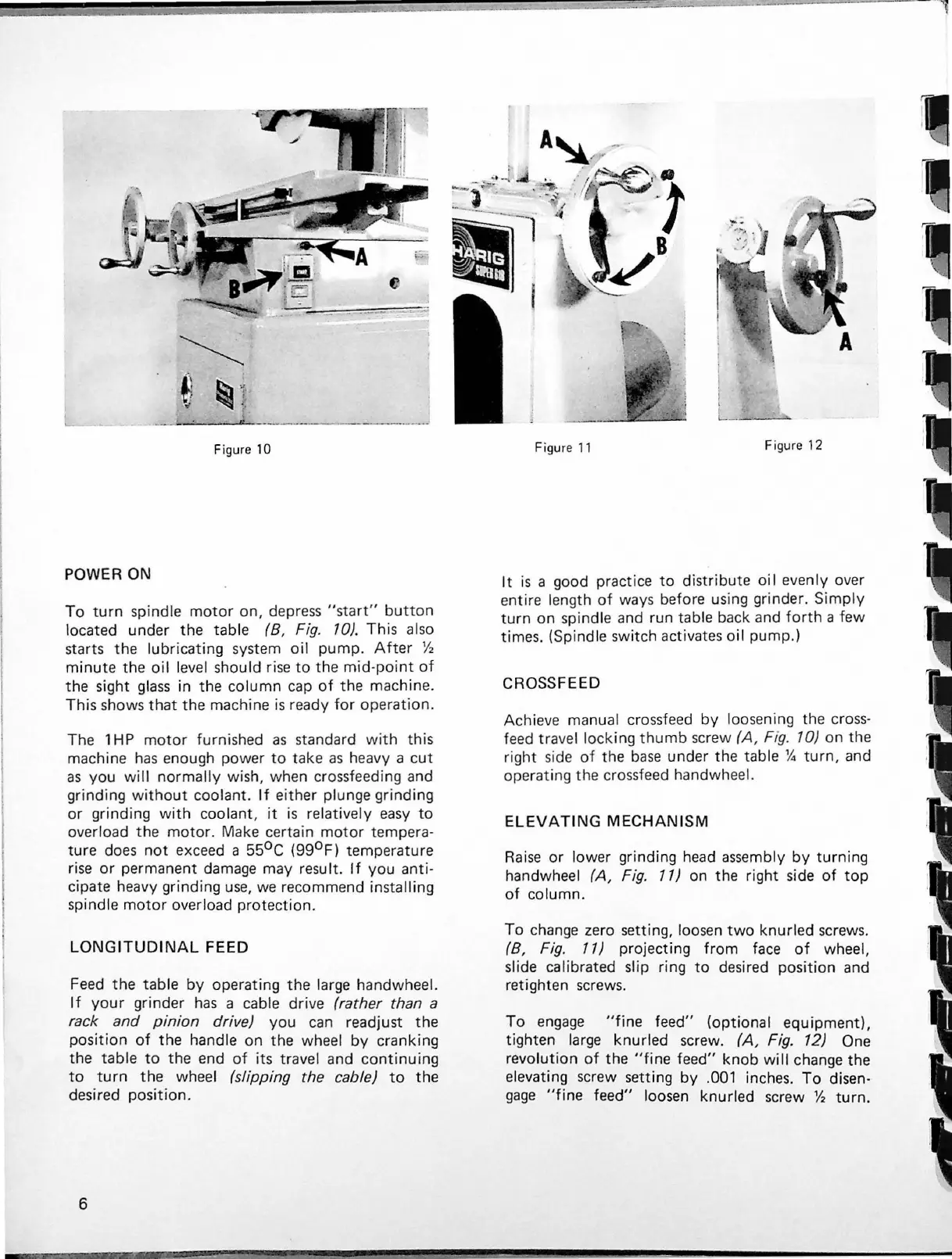

Figure 10

POWER ON

To

turn

spindle

motor

on

, depress

"start"

button

located under

the

table

(8,

Fig. 10). This also

starts

the

lubrica

ting

system

oil

pump

.

After

½

minute

the

oil

level should rise

to

the

mid-point

of

the sight

glass

in

the

column

cap

of

the machine.

Th

is

shows that

the

machine

is

ready

for

operation

.

The 1

HP

motor

furnished

as

standard

with

this

machine

has

enough power

to

take

as

heavy a

cut

as

you

will

normally

wish, when crossfeeding and

grinding

without

coolant.

If

either plunge grinding

or

grinding

with

coolant,

it

is

relative

ly

easy

to

overload

the

motor

. Make certain

motor

tempera-

ture

does

not

exceed a

55°C

(99°F)

temperature

rise

or

permanent damage may result.

If

you

anti-

cipate heavy grinding

use,

we

recommend installing

spindle

motor

overload protection.

LONGITUDINAL

FEED

Feed the

table

by

operating

the

large handwheel.

If

your

grinder

has

a cable drive

(rather

than a

rack

and

pinion

drive) you can readjust

the

position

of

the

handle

on

the wheel

by

cranking

the table

to

the

end

of

its travel and

continuing

to

turn

the

wheel (slipping

the

cable)

to

the

desired

position

.

6

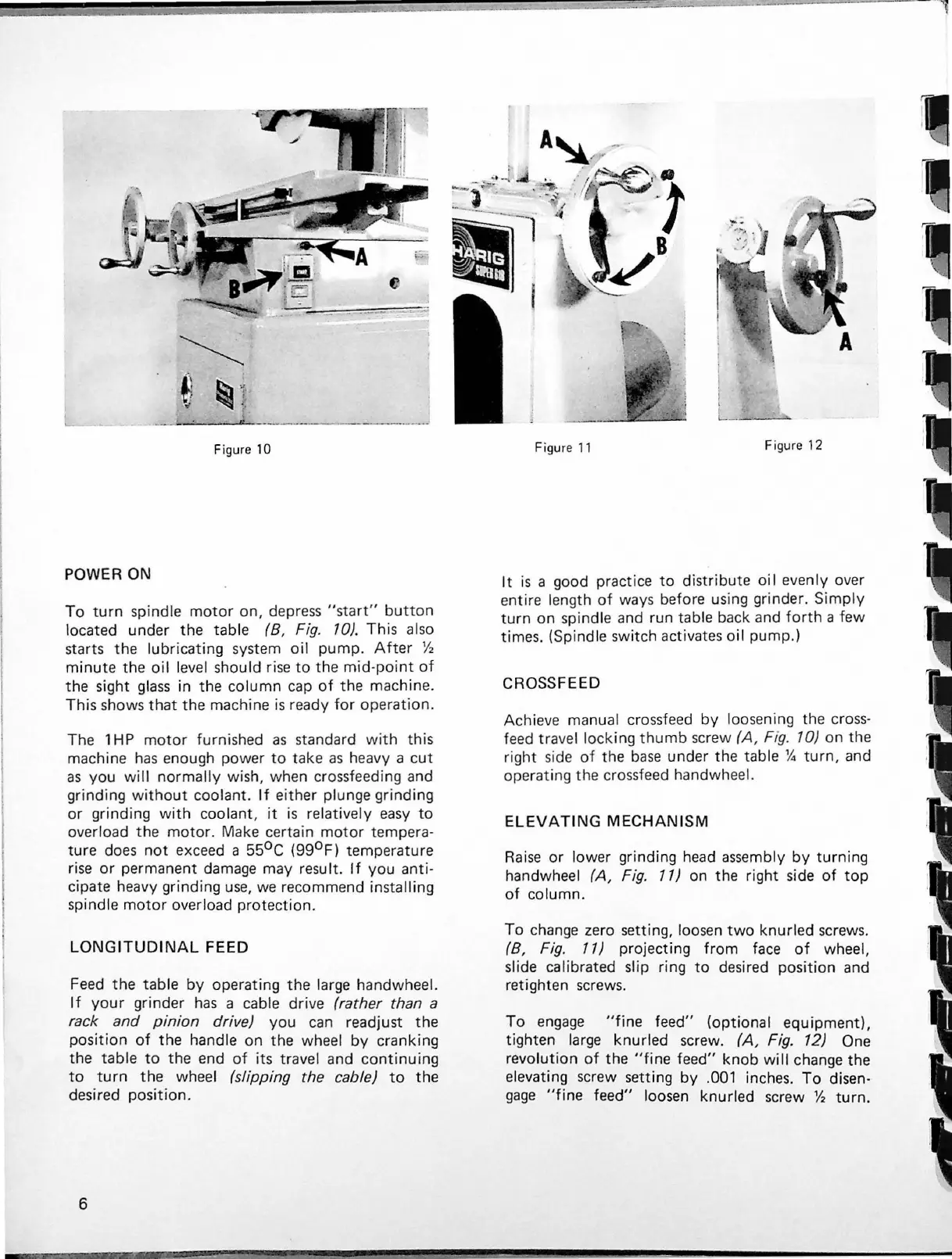

Figure 11

Figure 12

It

is

a good practice t o

distribute

oil

evenly over

en

tire

length

of

ways before using grinder. Si

mply

turn

on

spindle and run table back and

forth

a few

times. (Sp

in

dle switch activates

oil

pump.)

CROSSFEED

Achieve manual crossfeed

by

loosening the cross-

feed travel locking

thumb

screw (A , Fi

g.

10)

on

the

right side of the

base

under

the

table ¼

turn

, and

operating the crossfeed handwheel.

ELEVATING

MECHANISM

Raise

or

lower grinding h

ead

assemb

ly

by

turning

handwheel (A, Fig. 11) on

the

right side

of

top

of

co

lumn.

To

change zero setting, loosen

two

knurled

screws.

(8,

Fig

. 11) projecting

from

face

of

wheel,

slide

ca

librated

sl

ip ring

to

desired

position

and

retighten screws.

To

engage

"

fine

feed"

(optional equipment),

tighten large knurled screw. (A,

Fig

. 12) One

revolution

of

the

"fine

feed"

knob

wi

II

change

the

elevating screw setting

by

.001 inches.

To

disen-

gage

"fine

feed"

loosen knurled screw ½

turn.

Loading...

Loading...