L -

~,

I'.,

..

- •

·1

:

~

<

\

~ - --

. '

\

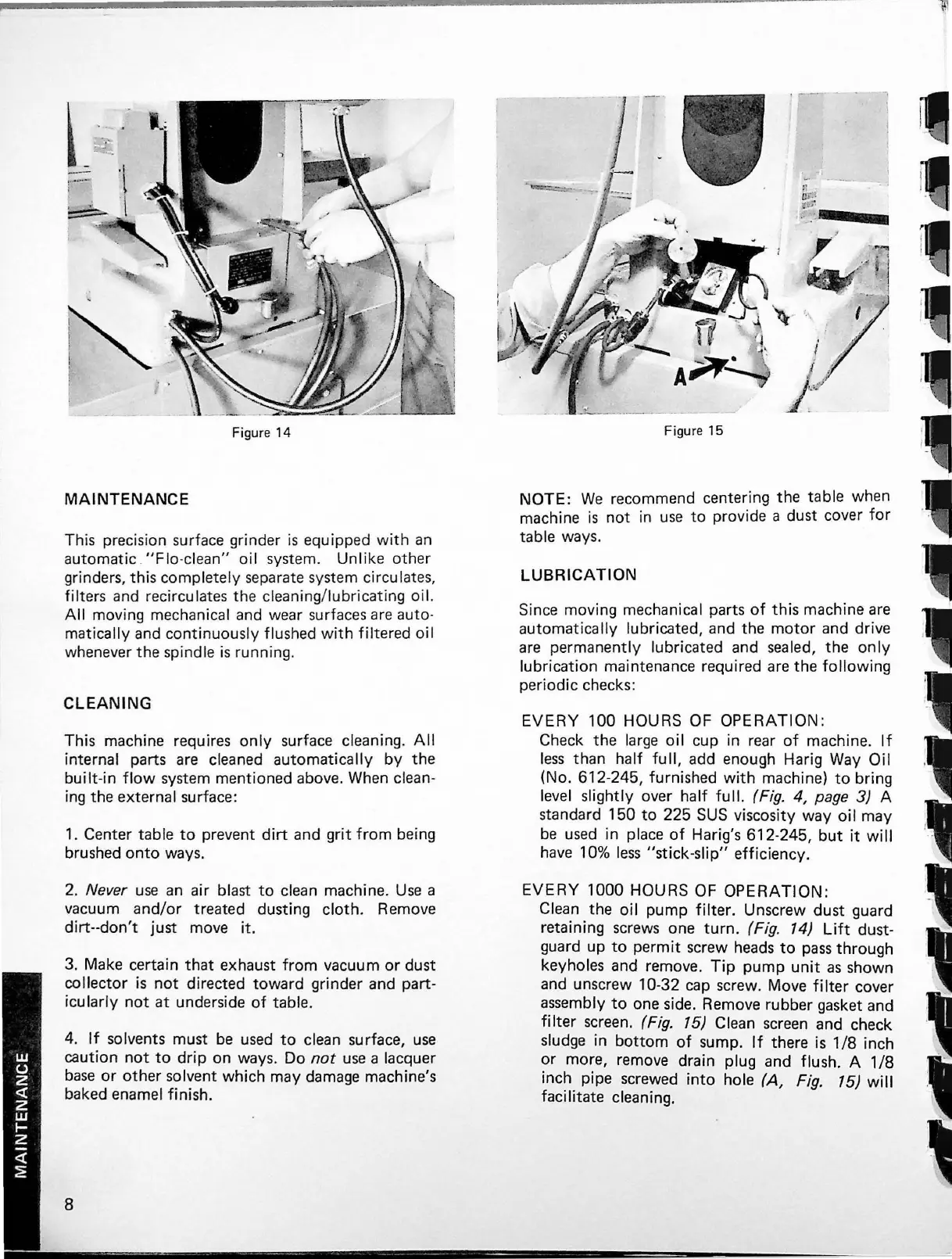

Figure 14

MAINTENANCE

This precision surface grinder

is

equipped

with

an

automatic .

"Flo-clean"

oil

system.

Unlike

other

grinders, this completely separate system circulates,

filters and recirculates the cleaning/lubricating oil.

All

moving mechanical and wear surfaces are auto-

matically and continuously flushed

with

filtered

oil

whenever the spindle

is

running.

CLEANING

This machine requires

only

surface cleaning.

All

internal parts

are

cleaned automatically

by

the

built-in

flow

system mentioned above. When clean-

ing the external surface:

1.

Center table

to

prevent

dirt

and

grit

from

being

brushed

onto

ways.

2. Never

use

an

air

blast

to

clean machine.

Use

a

vacuum

and/or

treated dusting cloth. Remove

dirt--don't

just

move

it.

3. Make certain

that

exhaust

from

vacuum

or

dust

collector

is

not

directed toward grinder and part-

icularly

not

at

underside

of

table.

4.

If

solvents must

be

used

to

clean surface,

use

caution

not

to

drip

on ways. Do

not

use

a lacquer

base

or

other solvent which may damage machine's

baked enamel finish.

8

7

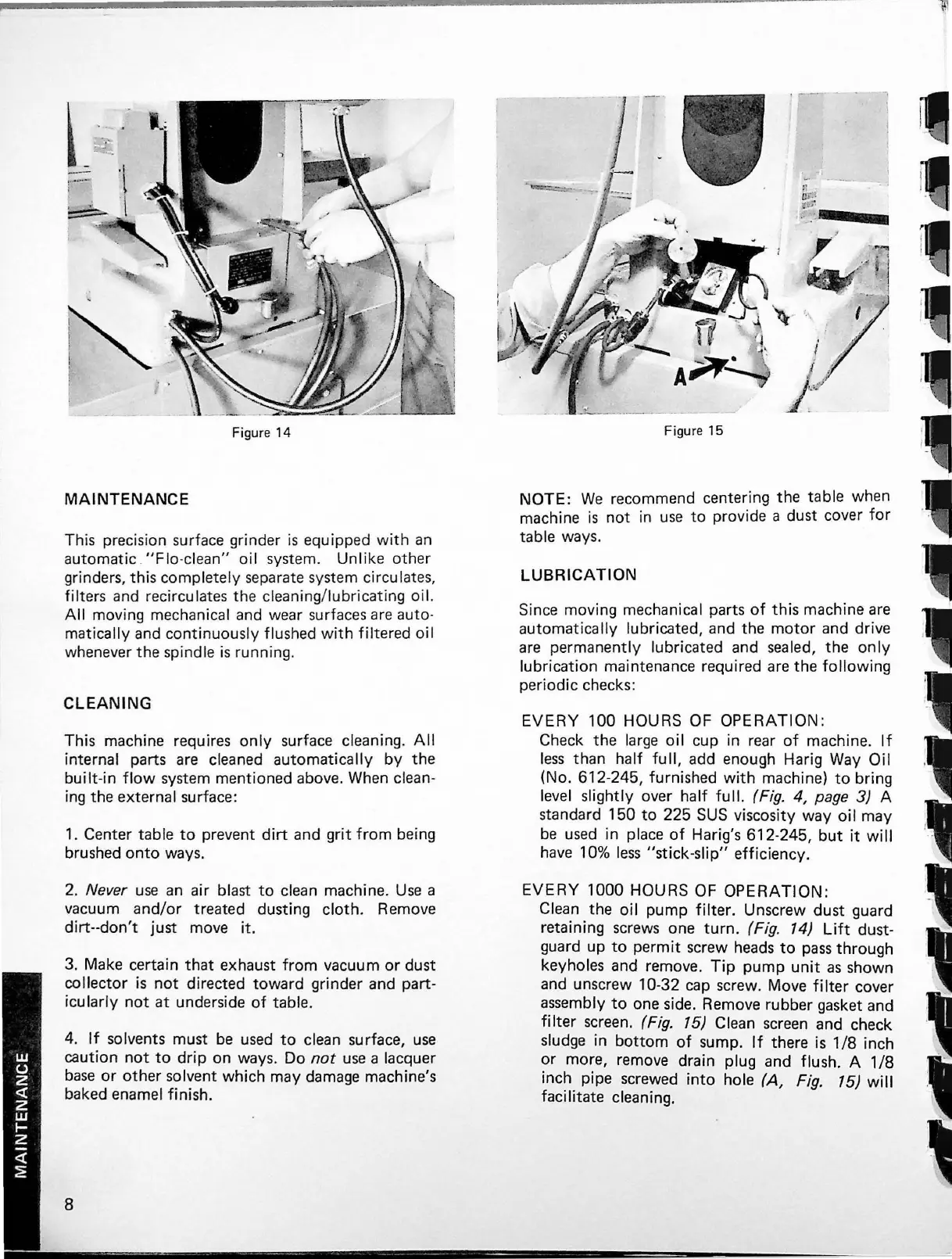

Figure 15

NOTE:

We

recommend centering

the

table when

machine

is

not

in

use

to

provide a dust cover

for

table ways.

LUBRICATION

Since moving mechanical parts

of

this

machine

are

automatically lubricated, and the

motor

and drive

are

permanently lubricated and sealed, the

only

lubrication maintenance required are

the

following

periodic checks:

EVERY

100 HOURS OF OPERATION:

Check the large

oil

cup in rear

of

machine.

If

less

than half

full,

add enough Harig Way

Oil

(No. 612-245, furnished

with

machine)

to

bring

level slightly over half

full.

(Fig. 4, page 3) A

standard 150

to

225

SUS

viscosity way

oil

may

be

used

in

place

of

Harig's 612-245,

but

it

will

have

10%

less

"stick

-

slip"

efficiency.

EVERY

1000 HOURS OF

OPERATION:

Clean the

oil

pump

filter.

Unscrew dust guard

retaining screws one

turn.

(Fig. 14)

Lift

dust-

guard up

to

permit

screw heads

to

pass

through

keyholes and remove.

Tip

pump

unit

as

shown

and unscrew 10-32 cap screw. Move

filter

cover

assembly

to

one side. Remove rubber gasket and

filter

screen. (Fig. 15) Clean screen and check

sludge

in

bottom

of

sump.

If

there is

1/8

inch

or

more, remove drain plug and flush. A

1/8

inch pipe screwed

into

hole (A, Fig. 15)

will

facilitate cleaning.

Loading...

Loading...