Chipper/Shredder

R

2. Connect the battery to a charger accord-

ing to the manufacturer’s instructions and

charge at 10 amperes for 50 minutes, or

2-9 amperes for 2 hours (depending on

capability of the charger).

Installation:

1. Make sure the cable terminals and any

hold-down parts are clean. If the battery is

a replacement and the connectors and

hold-down parts have been used before;

clean them with a wire brush.

2. Place the battery in the box with the

terminals on the side nearest the tongue,

and secure the battery in position with

hold-down parts provided.

3. Connect the cables to the proper

terminals, connecting the UNGROUNDED

cable rst. Do not over-tighten. Apply a

commercial battery anti-corrosion material

or petroleum jelly to the terminals to

minimize corrosion.

SAFETY WARNING!

• Battery electrolyte can cause se-

vere burns if handled improperly.

Observe all poison/danger warnings

on electrolyte cartons and on the

battery.

• Wear splash-proof goggles and

protective clothing when adding

electrolyte to batteries.

• Avoid contact of electrolyte with

skin, eyes, or clothing.

• Keep batteries and electrolyte OUT

OF REACH OF CHILDREN.

• If electrolyte is spilled or splashed

on the body, IMMEDIATELY FLUSH

WITH WATER.

• If electrolyte comes into contact

with the eyes, FLUSH WITH

WATER FOR 15 MINUTES AND GET

PROMPT MEDICAL ATTENTION.

• If electrolyte is taken internally,

DRINK LARGE QUANTITIES OF

WATER OR MILK, FOLLOWED WITH

MILK OF MAGNESIA, BEATEN

EGGS, OR VEGETABLE OIL.

SAFETY WARNING!

• The battery can produce explosive

gases. Ventilate when charging or

using in an enclosed space.

• DO NOT produce sparks from cable

clamps, tools or other sources.

• DO NOT allow ames or smoking in

the vicinity of the battery.

• Shield eyes when working near the

battery.

• Keep the vent caps tight and level.

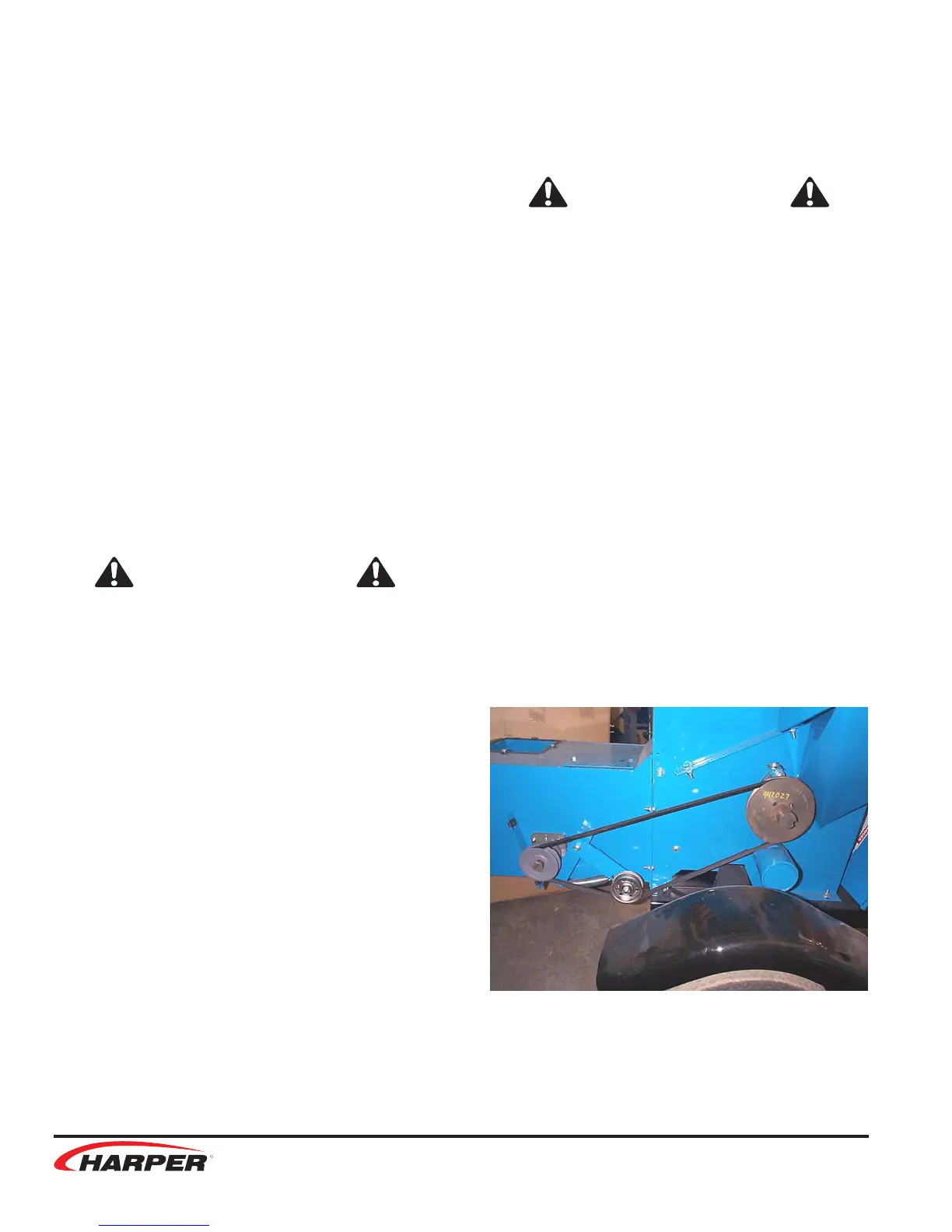

Blower Attachment

1. Remove blower and directional spout from

boxes.

2. Remove rear shaft guard and safety door

from Chipper/Shredder.

3. Mount blower attachment to Chipper/

Shredder using safety door hinge pin,

secure blower to unit using 4 - 5/16” x 3/4”

bolts and 5/16” nylock nuts.

4. Install belt shield mount tab on top bolt of

bearing using 1/2” lock nut.

10

Loading...

Loading...