Chipper/Shredder

R

5. Mount drive pulley on drum shaft. Align

pulleys and tighten to 17 ft-lb. Mount belt

on unit routing idler in center of belt.

Install belt shield using 5/16” bolts and at

washers.

6. Mount lower directional spout to blower

using 5/16” bolts and at washers.

7. Mount upper directional spout to lower

using 5/16” x 3/4” bolts, 5/16” lock nuts

and bearings. Make sure that 1/4” washer

is placed between bearing and mount tab.

8. Mount crank assembly to mount tab using

2 3/8” x 1” carriage bolts and 3/8” nylock

nuts. Place 2 3/8” at washers under each

bolt location to shim up crank assy.

NOTE: This may vary due to required

clearance for crank.

9. Mount deector spout to upper spout

using 2 5/16” x 34” truss head bolts. A

5/16” washer is used for a spacer

between deector and spout.

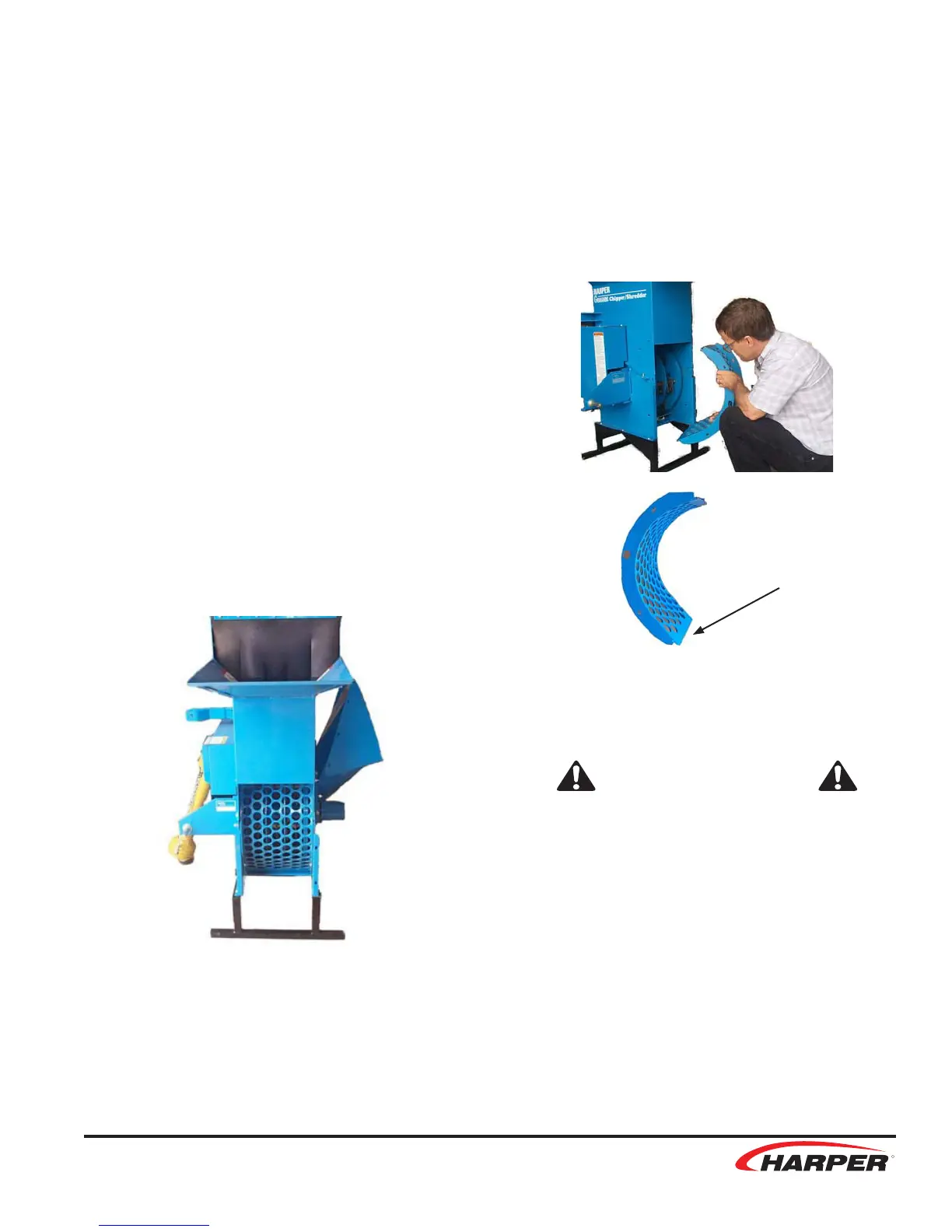

Discharge Grates

• The factory-installed standard dis-

charge grate has 1½” diameter holes.

• Installing a discharge grate with small-

er diameter holes can increase ne-

ness of the shredded material.

• Discharge grates with ½” and ¾” diam-

eter holes are available for the Chip

per/Shredder.

• A discharge grate with parallel bars is

available for shredding leaves or green

material.

To change discharge grates:

1. Remove the rear door hinge pin and

remove the rear safety door.

2. Remove the 6- 3/8” x 1” bolts holding the

grate in place. Remove the grate.

3. Install new grate. Make sure to install the

rounded edge of the grate to the bottom.

4. Reinstall bolts and rear safety door.

SAFETY WARNING!

• The cutting rotor is heavy and will

continue to turn even though the

operator has shut off the power

source. Do not attempt to service or

inspect the machine until you see

that the shafts have stopped turn-

ing and that there is no noise com-

ing from the machine.

• Never operate Chipper/Shredder

without ALL GUARDS in place.

Install this

end down

11

Loading...

Loading...