Chipper/Shredder

R

SAFETY WARNING!

• The cutting rotor is heavy and will

continue to turn even though the

operator has shut off the power

source. Do not attempt to service or

inspect the machine until you see

that the shafts have stopped turn-

ing and that there is no noise com-

ing from the machine.

• If the operator wants to slow the

machine faster, he can do so by

inserting a limb into the chipper

chute so that it contacts the knives

and slows the machine down.

• Never operate Chipper/Shredder

without ALL GUARDS in place.

Belt Tension

• On initial operation of the Chipper/

Shredder, the belts may shrink and

need readjustment after the rst hour

of use.

• Check the condition of drive belts be-

fore each use or after every 25 hours

of operation.

• Use only industrial V-belts. Do not use

automotive belts.

• Do not over tighten belts. Excessive

tension can cause premature bearing

and belt failure.

• Use a straightedge to check alignment

across the faces of pulleys after ad-

justing belt tension to ensure that the

belts will run true.

Belt Adjustment

CS-5400 PTO Powered Model

1. Make certain that PTO shaft is removed

from power source and un-mounted from

3-point hitch of tractor.

2. Disconnect PTO shaft from Chipper/

Shredder and remove belt guards.

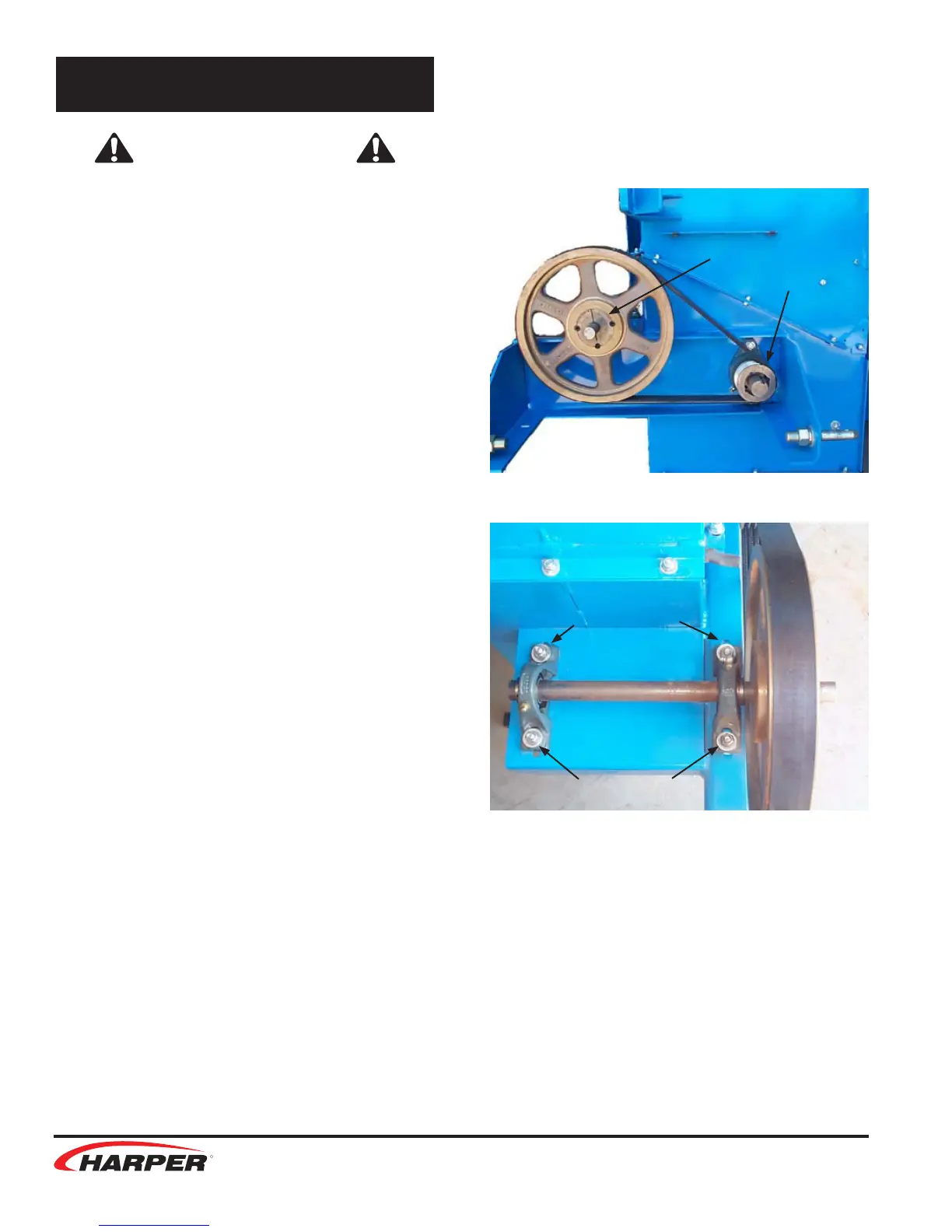

3. Loosen bolts that mount the jackshaft

pillow block bearings and move the shaft

towards the frame.

4. Remove the belt. Inspect or replace with a

new belt.

5. Move shaft away from frame to tighten

belt and check to see that there is no

more than 1/4” up and down play in the

belt.

6. Snug two bolts and check pulley alignment

with a straightedge. If not aligned, loosen

one bolt and adjust. Tighten all bolts on

bearings when alignment is achieved.

Adjustments

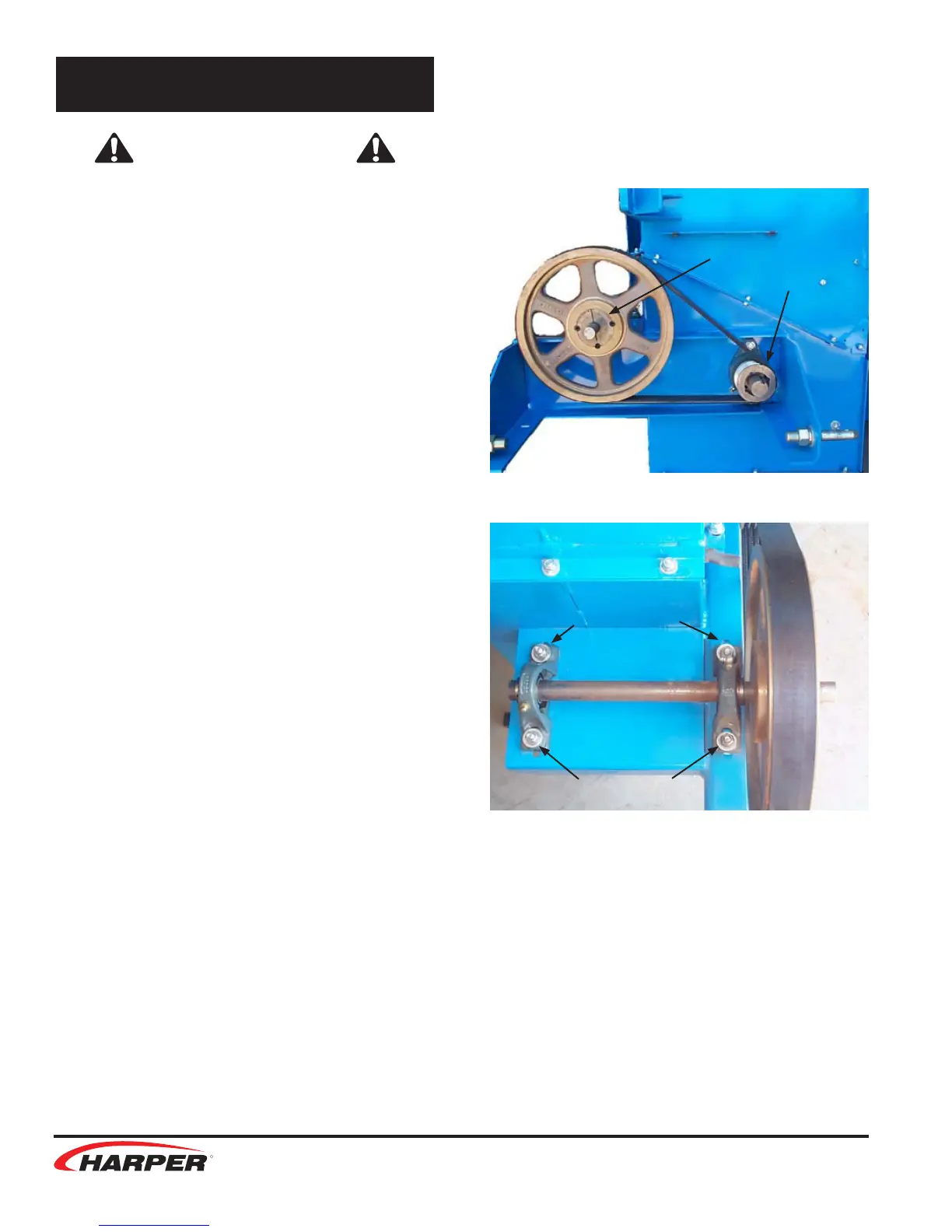

Jackshaft

Loosen &

Adjust Here

Loosen &

Adjust Here

Rotor Shaft

14

Loading...

Loading...