23 – English

BEVEL CUT

TO BEVEL CUT

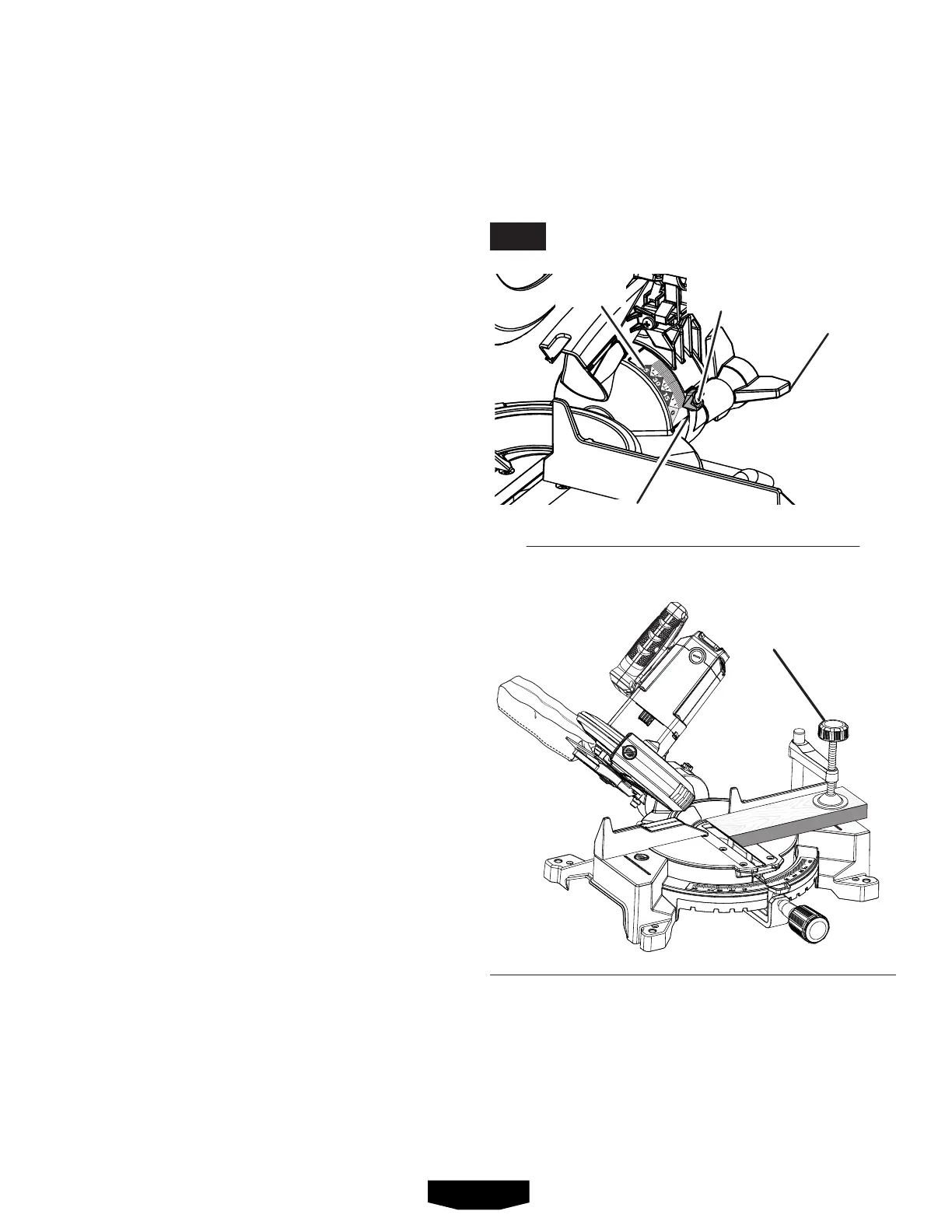

See Figure 27.

Abevelcutis made by cuttingacross the grain of the

workpiecewiththebladeangledtotheworkpiece.Astraight

bevelcutismadewiththemitertablesetatthezerodegree

positionandthebladesetatananglebetween0°and45°.

NOTE:Itmaybenecessarytoadjustthepartialslidingmiter

fencetoensureproperclearancepriortomakingthecut.

Pulloutthelockpinandliftsawarmtoitsfullheight.

Loosenthemiterlockknobapproximatelyone-halfturn

andpressthedetentreleasebutton.

Rotatethecontrolarmuntilthepointeralignswiththe

desiredangleonthemiterscale.

Releasethedetentreleasebutton,thentightenthemiter

lockknobtosecurethemitertable.

NOTE: Youcanquicklylocate0°,15°,22.5°,31.6°,and

45°leftorrightbyreleasingthedetentreleasebuttonas

yourotatethecontrolarm.Thecontrolarmwillseatitself

inoneofthepositivestopnotches,locatedinthemiter

tablebase.

Loosenthebevellockknobandmovethesawarmtothe

lefttothedesiredbevelangle.

Bevelanglescanbesetfrom0°to45°.

Aligntheindicatorpointforthedesiredangle.

Once thesawarmhasbeen setatthedesired angle,

securelytightenthebevellockknob.

Placetheworkpieceflatonthemitertablewithoneedge

securelyagainstthefence.Iftheboardiswarped,place

theconvexsideagainstthefence.Iftheconcaveedge

ofaboardisplacedagainstthefence,theboardcould

collapseonthebladeattheendofthecut,jammingthe

blade.See figures 32 - 33.

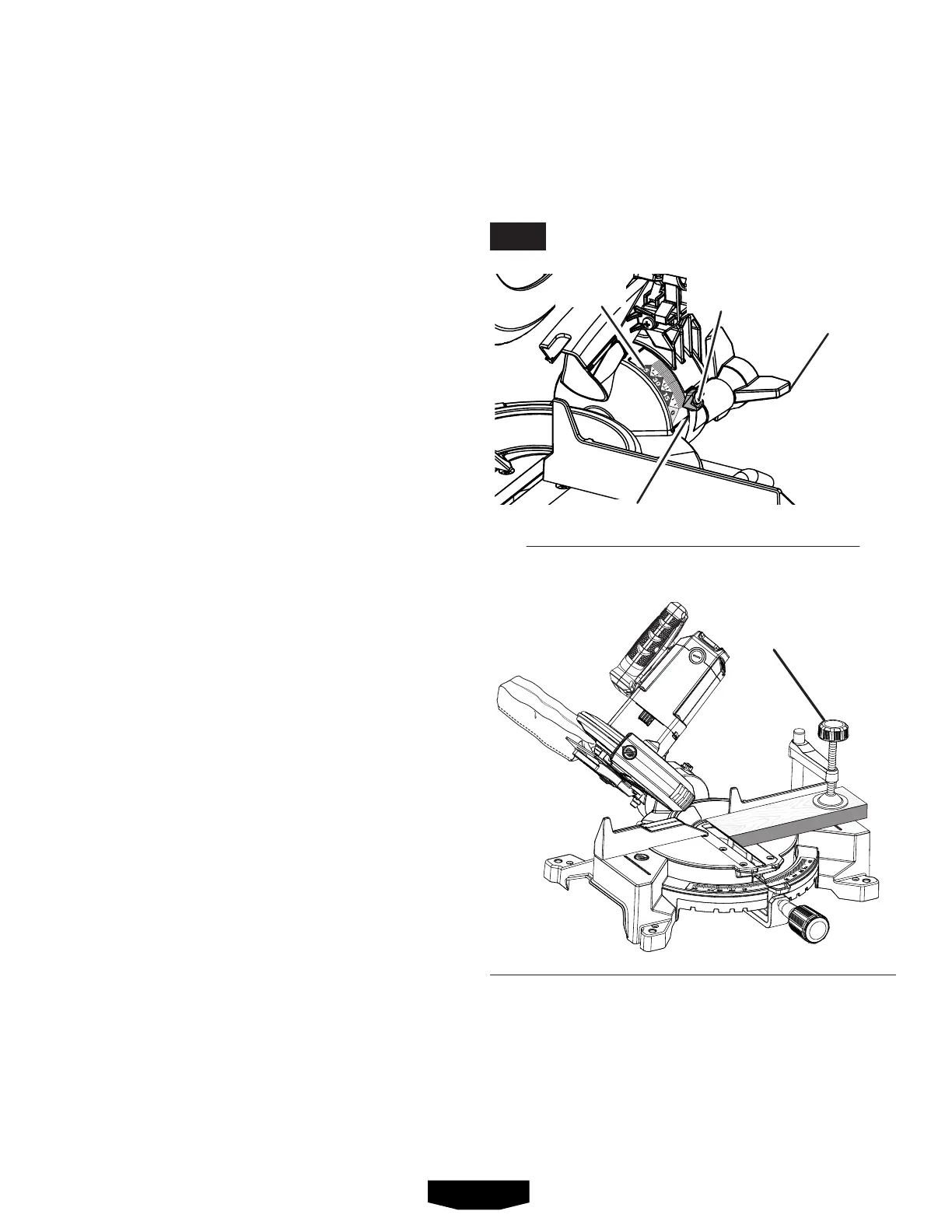

Whencuttinglongpiecesoflumberormolding,support

theoppositeendofthestockwitharollerstandorwith

aworksurfacelevelwiththesawtable.See figure 30.

Grasptheworkpiecefirmlywithonehandandsecureit

againstthefence.Usetheworkclamp,C-clamp,orother

suitableclamptosecuretheworkpiecewhenpossible.

Beforeturningonthesaw,performadryrunofthecutting

operationjusttomakesurethatnoproblemswilloccur

whenthecutismade.

Graspthesawhandlefirmly.Depressthetriggerlockout

leverandsqueezetheswitchtrigger.Allowseveralsec-

ondsforthebladetoreachmaximumspeed.

Slowlylowerthebladeintoandthroughtheworkpiece.

Releasetheswitchtriggerandallowthesawbladetostop

rotatingbeforeraisingthebladeoutoftheworkpiece.

Waituntilthebladestopsturningbeforeremovingthe

workpiecefrommitertable.

SCALE

INDICATOR

INDICATOR

SCREW

BEVEL LOCK

KNOB

BEVEL

SCALE

WORK

CLAMP

OPERATION

FIG. 27

Loading...

Loading...