39

5.3.2. Procedure.

IMPORTANT:

• For refilling and greasing, use only lubricants specified in the chart in § 5.2.

• Retrieve the drained oils in order not to pollute the environment.

5.3.2.1. Hydraulic oil filter.

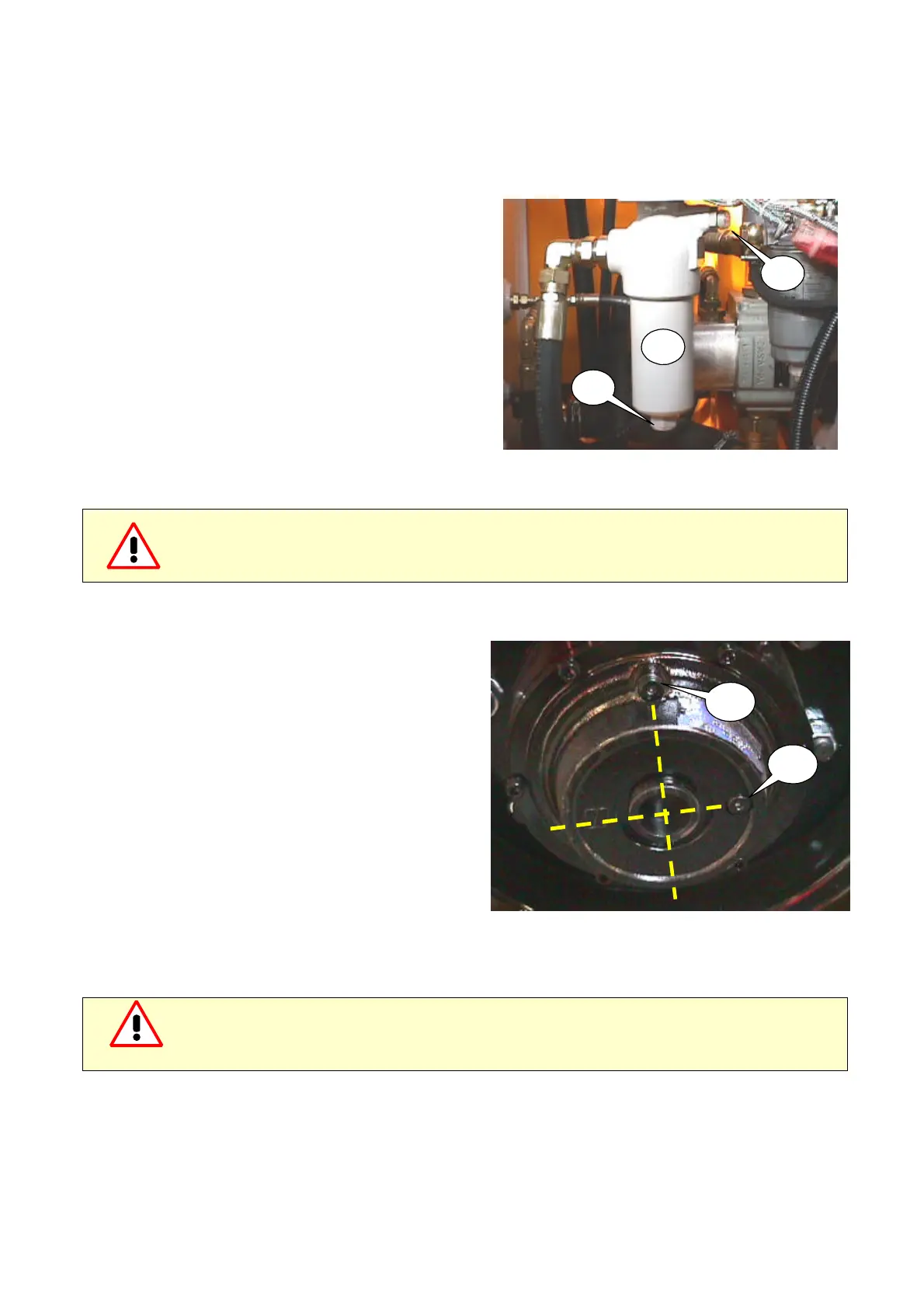

See photo 14.

The filter contains a clogging indicator (1).

Change the cartridge (2) if the clogging light in the

indicator comes on.

1 - unscrew base nut (3) and remove cartridge.

2 - screw on a new cartridge.

NOTE: the clogging check must be done when the

engine is hot; if the engine is cold, the light may come on

due to oil viscosity.

1

2

3

Photo 14 : Hydraulic oil filter.

WARNING.

Before disassembly, ensure that the oil circuit is no longer pressurised

and that the oil has cooled sufficiently.

5.3.2.2. Drive-wheel reducing gears.

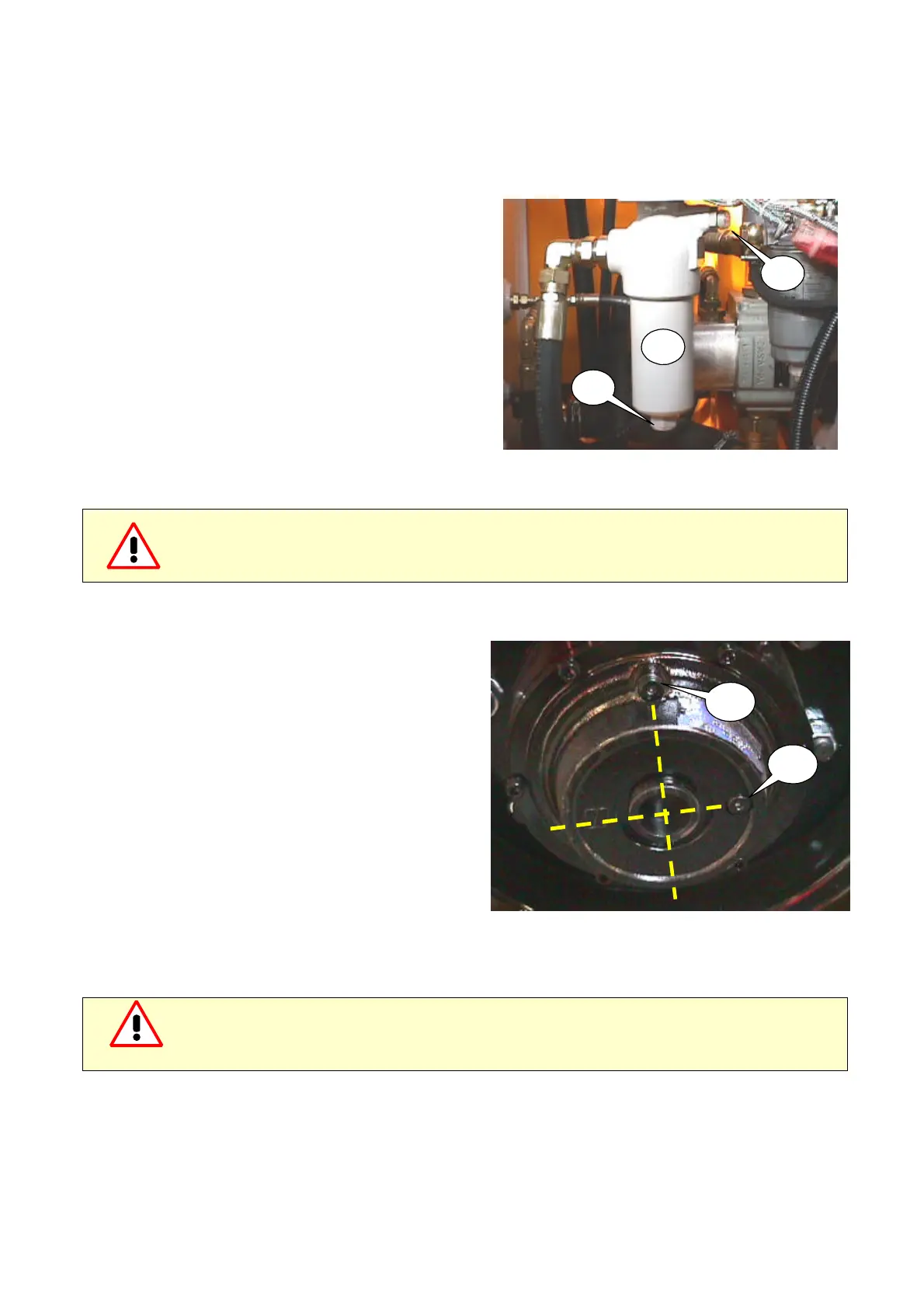

See photo 15.

Checking and draining require wheel dismounting: to do

this, immobilise the machine and lift using a jack or

hoist.

• Level check:

− turn the wheel so that one plug (1) is on a

horizontal line and one plug (2) on a vertical line.

− unscrew the plug (1) and check the level: this

must be level with the hole. Top up if necessary.

− Screw plug back on.

• Draining:

− With wheel in same position, unscrew the two

plugs and let the oil pour out.

− Refill as described above.

− Screw plugs back on.

1

2

Photo 15 : Drive-wheel reducing gears.

WARNING.

Ensure that the machine is adequately secured,

and that the lifting gear is of ample capacity and in good order.

Loading...

Loading...