46

www.coreservice.co.uk

Hotline: +44 01904 947568

Email support@coreservice.co.uk

- All cutter lengths must be equal. Different cutter lengths prevent the saw chain from running

smoothly and may cause the saw chain to break.

- Do not sharpen the chain when the cutter length has reached 3 mm or shorter. The chain must be

replaced with a new one.

- The chip thickness is determined by the distance between the depth gauge (round nose) and the

cutting edge.

- The best cutting results are obtained with following distance between cutting edge and depth

gauge.

• Chain blade 91PX: 0.65 mm (0.025”)

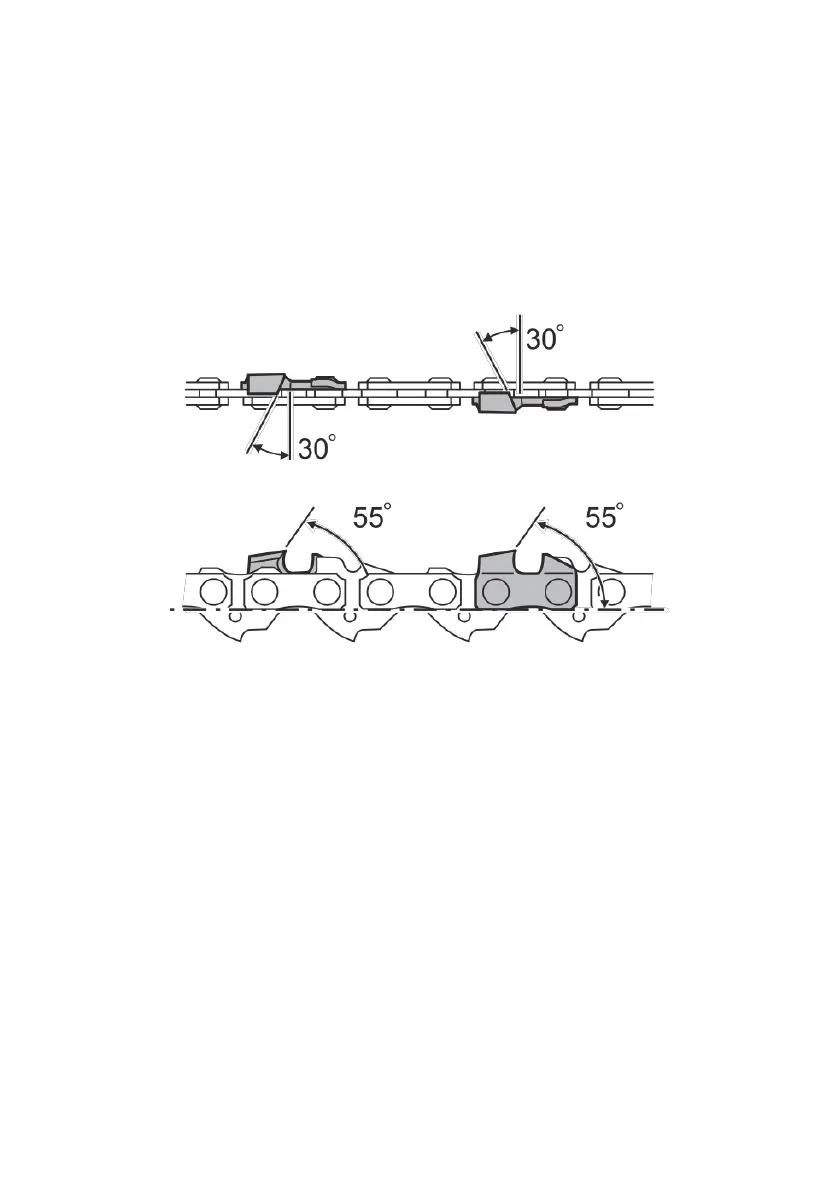

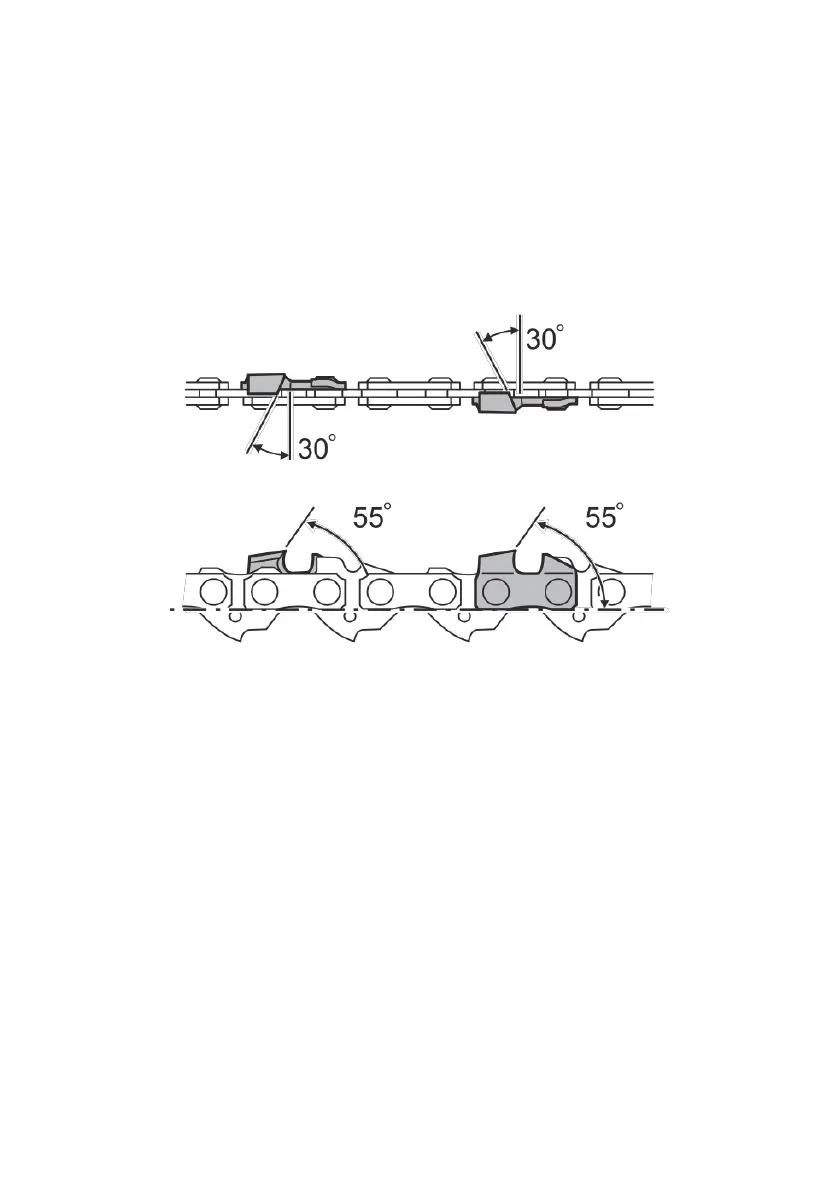

- The sharpening angle of 30° must be the same on all cutters. Different cutter angles cause the

chain to run roughly and unevenly, accelerate wear, and lead to chain breaks.

- Use a suitable round file so that the proper sharpening angle is kept against the teeth.

• Chain blade 91PX : 55°

File and file guiding

- Use a special round file (optional accessory) for saw chains to sharpen the chain. Normal round

files are not suitable.

- Diameter of the round file for each saw chain is as follows:

• Chain blade 91PX : 4.0 mm (5/32")

- The file should only engage the cutter on the forward stroke. Lift the file off the cutter on the

return stroke.

- Sharpen the shortest cutter first. Then the length of this shortest cutter becomes the standard for

all other cutters on the saw chain.

Loading...

Loading...