Hayward Flow Control www.haywardflowcontrol.com 1-888-HAY-INDL (1-888-429-4635)

TCIS Rev D 5/15/18

Pg. 4 of 11

1.2.4.1.2. Thread the end connector onto the threaded pipe end until “hand tight”. Using a strap wrench only (never use a pipe

wrench), tighten the end connector onto the pipe only to the point required to form a seal between the end

connector and pipe thread; 1/2 turn past hand tight is typically sufficient to form a seal. (Caution: Tightening beyond

this point may introduce excessive stress that could cause failure of the end connector or the threaded end of

the pipe.)

1.2.4.2. Solvent-Weld End Connectors (PVC and CPVC only):

CAUTION

Valve center cartridge must be disassembled from nuts and end connectors prior to solvent cementing end connections into

system, Avoid exposing valve cartridge and end connector o-rings to primer, solvent cement, or their fumes, as damage to the

valve could result.

1.2.4.2.1. Refer to solvent-cement manufacturer’s instructions and cure times.

1.2.4.2.2. Do not install valve cartridge until solvent cement has fully cured. Reinstall end connectors by threading nuts

onto body by rotating in a clockwise direction.

1.2.4.3. Fusion-Weld End Connectors (PP and PVDF only):

1.2.4.3.1. Refer to pipe supplier’s procedure or your internal fusion procedure.

1.2.4.4. Flange Connections:

1.2.4.4.1. NOTE: When provided with flanges, TC Series True Union Ball Check Valves are provided with an end connection sub-

assembly, consisting of an end connector, solvent cemented to a flange, with an assembly nut for connection to the

valve.

1.2.4.4.2. Flange bolts should be tight enough to compress the gasket and make a good seal, without distorting or putting

excessive stress on the flanges. Suitable washers should be used between the bolt head and flange and the nut and

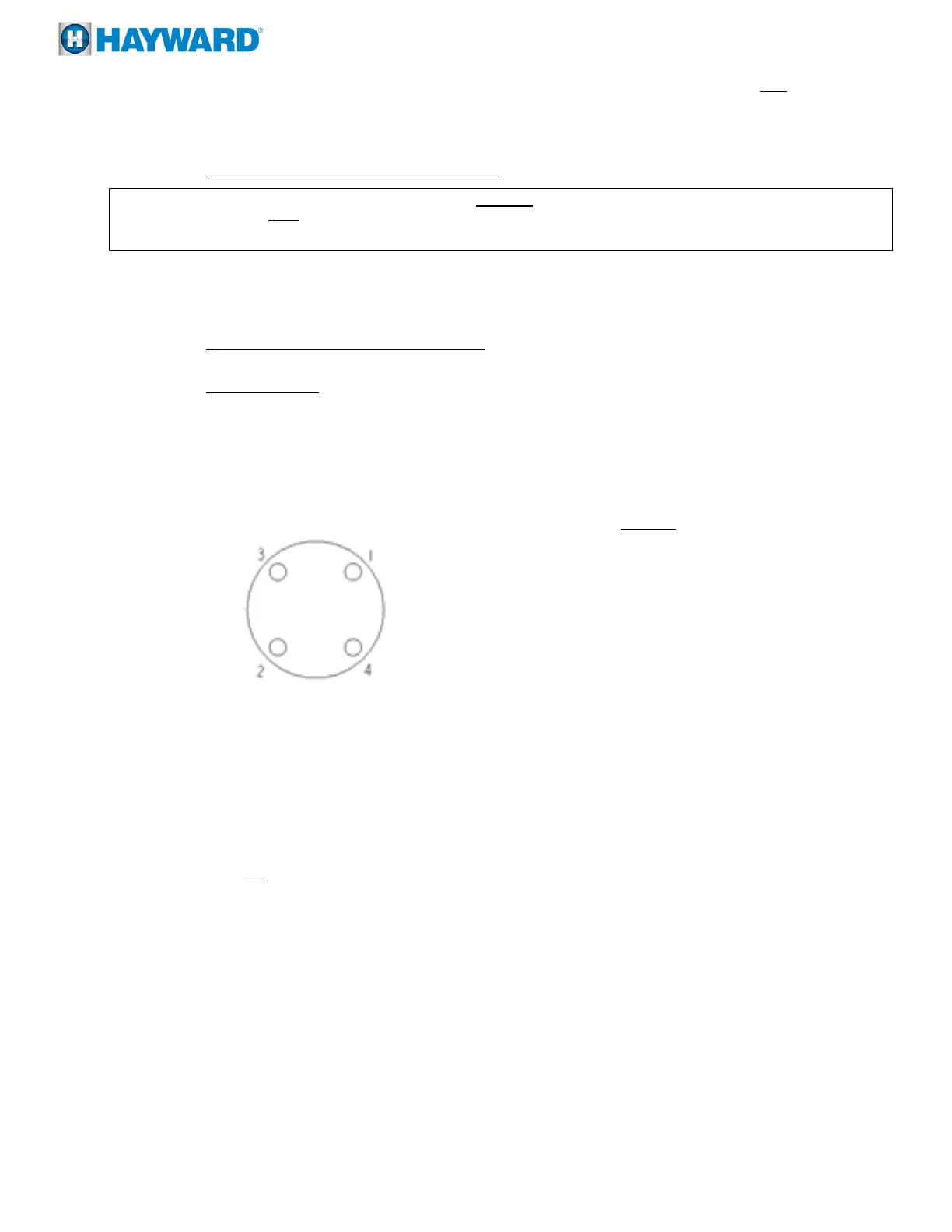

flange. Bolts should be tightened in alternating sequence (Figure 1). See Table 1 for recommended torque.

Figure 2: Bolt Tightening Sequence

TABLE 1:

RECOMMENDED FLANGE BOLT TORQUE

1.2.5. Install valve cartridge between end connectors, match nuts to body threads and turn nut clockwise to thread onto body. Using a

strap wrench only (never use a pipe wrench), nut can be tightened ¼ - ½ turn past hand-tight, as needed.

1.2.5.1. Never install valve into system where assembly nuts have to be used to pull system together. This will apply undue loading

on the valve body and assembly nuts. Piping system should be properly aligned prior to valve installation.

1.2.5.2. Never install valve into system that must be forcibly separated in order to allow space for body. This will apply undue loading

on the valve body.

Loading...

Loading...