Hayward Flow Control www.haywardflowcontrol.com 1-888-HAY-INDL (1-888-429-4635)

TCIS Rev D 5/15/18

Pg. 3 of 11

1. INSTALLATION:

1.1. Transporting the Valve:

Valve should be stored inside factory packaging until product is ready to be installed. Packaged valve should be stored indoors, at room

temperature, and out of direct sunlight. Avoid storing packaged valve in location where packaging may become wet. Valve should be moved

as close to installation site as possible prior to removing from packaging. Do not cut through tape on box any more than necessary to avoid

damaging valve. After removing valve from carton, care must be taken not to damage valve or to allow debris to enter valve.

1.2. Installing the Valve into a System:

1.2.1. Remove valve from packaging.

1.2.2. Verify that product is defect free and meets specifications.

1.2.3. Remove the nut and end connector by rotating the nuts counter clockwise. Verify end connector o-rings are installed in their

respective grooves.

1.2.4. Place nut over pipe end so that it can engage the end connector once the end connector is connected to the pipe end.

1.2.4.1. Threaded End Connectors:

1.2.4.1.1. Wrap male threads of pipe end with PTFE tape for seal on threaded joints.

WARNING

Do not use “pipe dope”, liquid sealant, or thread sealant on any PVC, CPVC, PP, or PVDF threaded connections. Pipe dope and

thread sealants may react with the PVC, CPVC, PP, or PVDF, weakening the material and potentially resulting in failure of the

joint, product damage, property damage, personal injury, or even death.

CAUTION

Do not install valve directly to pump outlet. Allow a length of at least 10 pipe diameters between pump outlet and valve.

Do not install valve directly after a reducer / expansion fitting. Install at least 10 pipe diameters from an expansion or reducing

fitting.

Pipe must be supported upstream and downstream of the valve. Sound piping system design principles should be applied

when installing this valve.

Do not install valve directly into a metal system (see pg. 2). Wherever installation of thermoplastic valves into metal piping

systems is necessary, it is recommended that at least 10 pipe diameters in length of thermoplastic pipe be installed upstream and

downstream of the thermoplastic valve.

When lifting valve do not lift by the handle.

WARNING

System must be depressurized and drained prior to installing valve or performing maintenance. Failure to depressurize and drain

system prior to installing or maintaining valve may result in product damage, property damage, personal injury, or even death.

NOTE

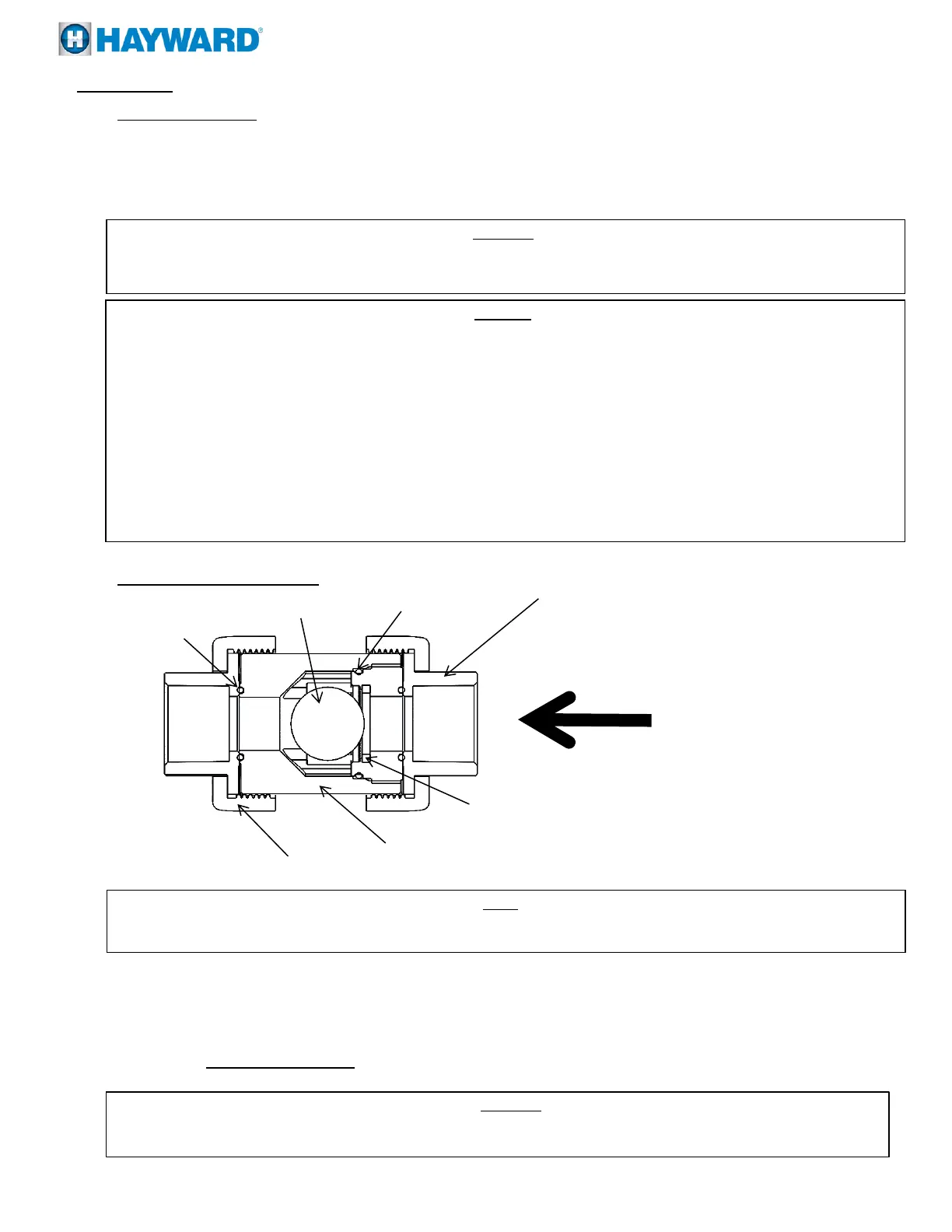

Hayward TC Series True Union Ball Check Valves with standard balls are uni-directional. There is a flow arrow marked on the

valve to indicate proper flow direction.

Loading...

Loading...