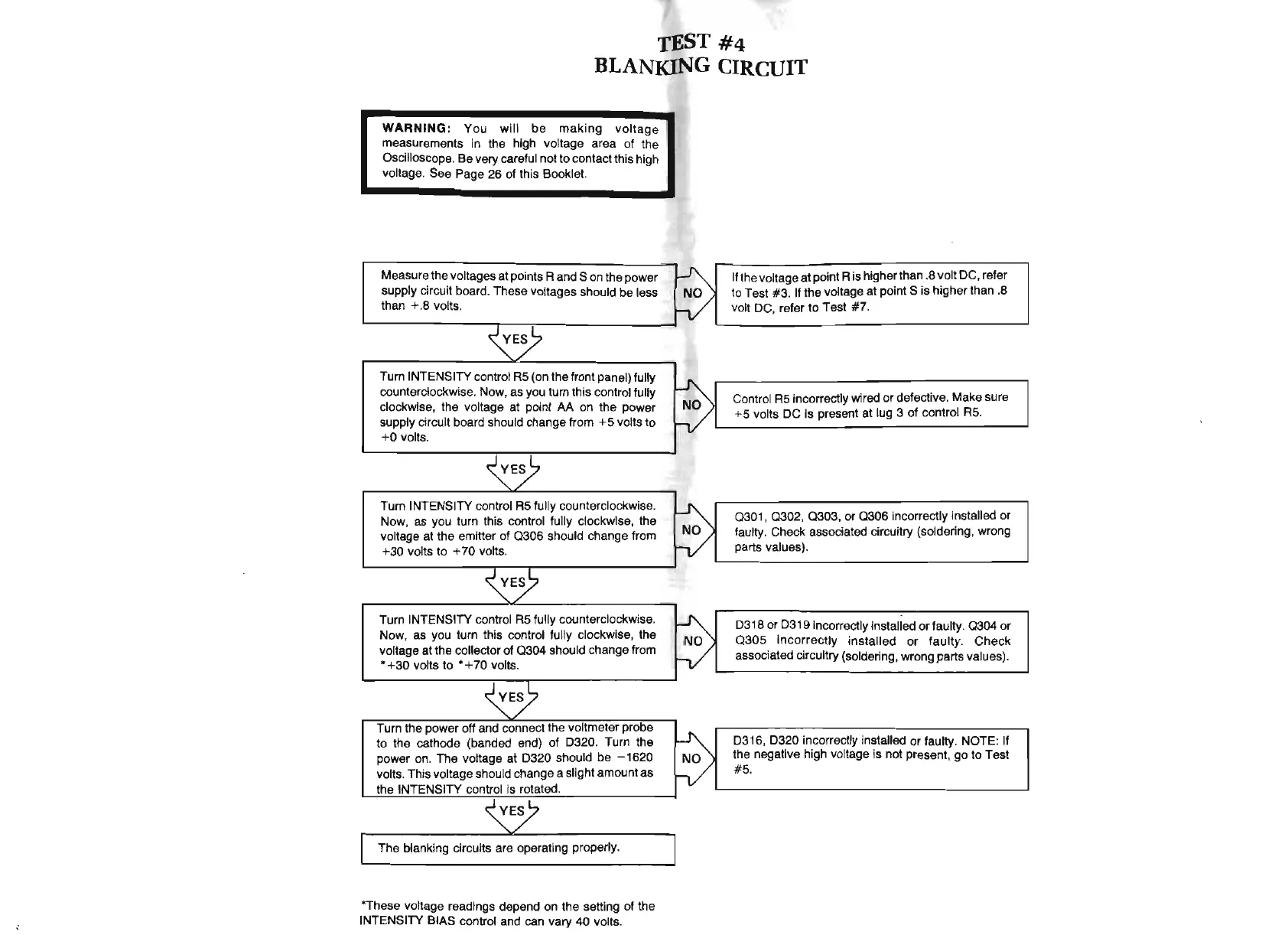

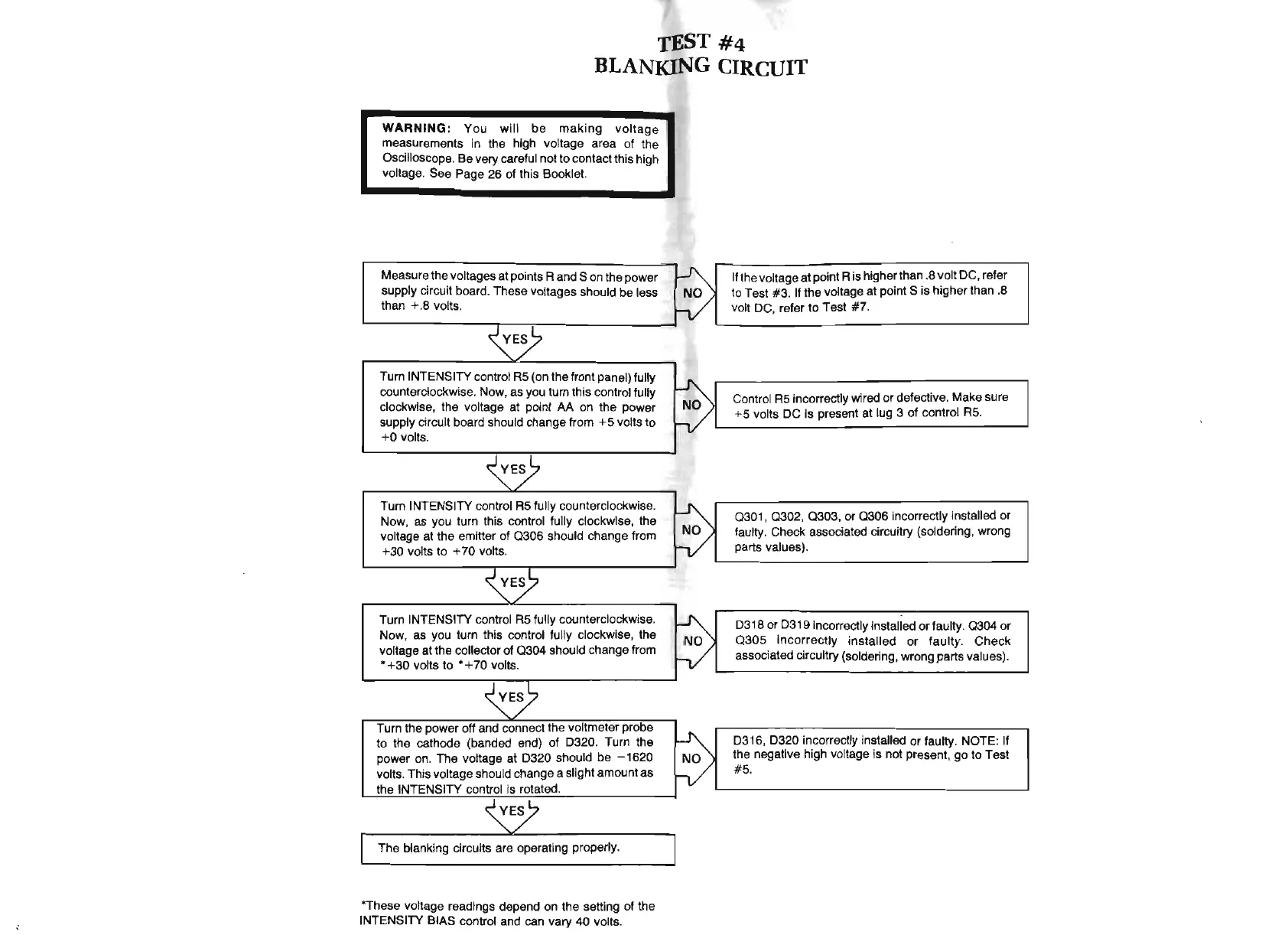

TEST

#4

BLANKING CIRCUIT

WARNING:

You

will

be

making

voltag

e

measurements in the high voltage area of the

Oscilloscope. Be very careful not

to

contact this high

voltage. See Page 26 of this Booklet.

Measure the voltages

at

points A and S on the power

supply circuit board. These voltages should be

less

than

+.

8 volts.

~

Turn INTENSITY control

AS

(on the front panel) fully

counterclockwise. Now, as you turn this control fully

clockwise, the voltage at point

AA

on the power

supply circuit board should change from + S volts

to

+0

volts.

~~

Turn INTENSITY control

AS

fully counterclockwise.

Now, as you turn this control

fully clockwise, the

voltage at the emitter of

0306

should change from

+ 30 volts

to

+ 70 volts.

~~

Turn INTENSITY control

AS

fully counterclockwise.

Now, as you turn this control fully clockwise, the

voltage at the collector of

0304

should change from

• +30 volts to • +

70

volts.

~~

Turn the power off and connect the voltmeter probe

to the cathode (banded end) of D320. Turn the

power on. The voltage at D320 should be

-1620

volts. This voltage should change a slight amount as

the INTENSITY control Is rotated.

~

The blanking circuits are operating properly.

*These voltage readings depend on the setting

of

the

INTENSITY BIAS control and can vary 40 volts.

~

If the voltage

at

point A is higher than .8 volt

DC

, refer

to Test #3. If the voltage

at

poi

ntS

is higher than .8

h/

volt DC, refer

to

Test

#7

.

~

h/

Control

AS

incorrectly wired

or

defective. Make sure

+S volts DC is present at lug 3 of con

tr

ol

AS

.

~

030

1,

0302

,

0303,

or

0306

incorrectly installed or

h/

faulty. Check associated circuitry (soldering, wrong

parts values).

~

D318

or

D319 incorrectly installed

or

faulty.

0304

or

030S

incorr

ectly installed

or

faulty

.

Check

h/

associated circuitry (soldering, wrong parts values

).

~

D316, D320 incorrectly installed

or

faulty. NOTE: If

the negative high voltage is not present, go to Test

h/

#S.

Loading...

Loading...