22

Parker Hannifin Corporation

Helac/Cylinder Division

Enumclaw, Washington USA

www.helac.com

Helical, Hydraulic Rotary Actuators

L20 Series Service & Repair Manual

Catalog HY34-1120

Greasing Thrust Washers

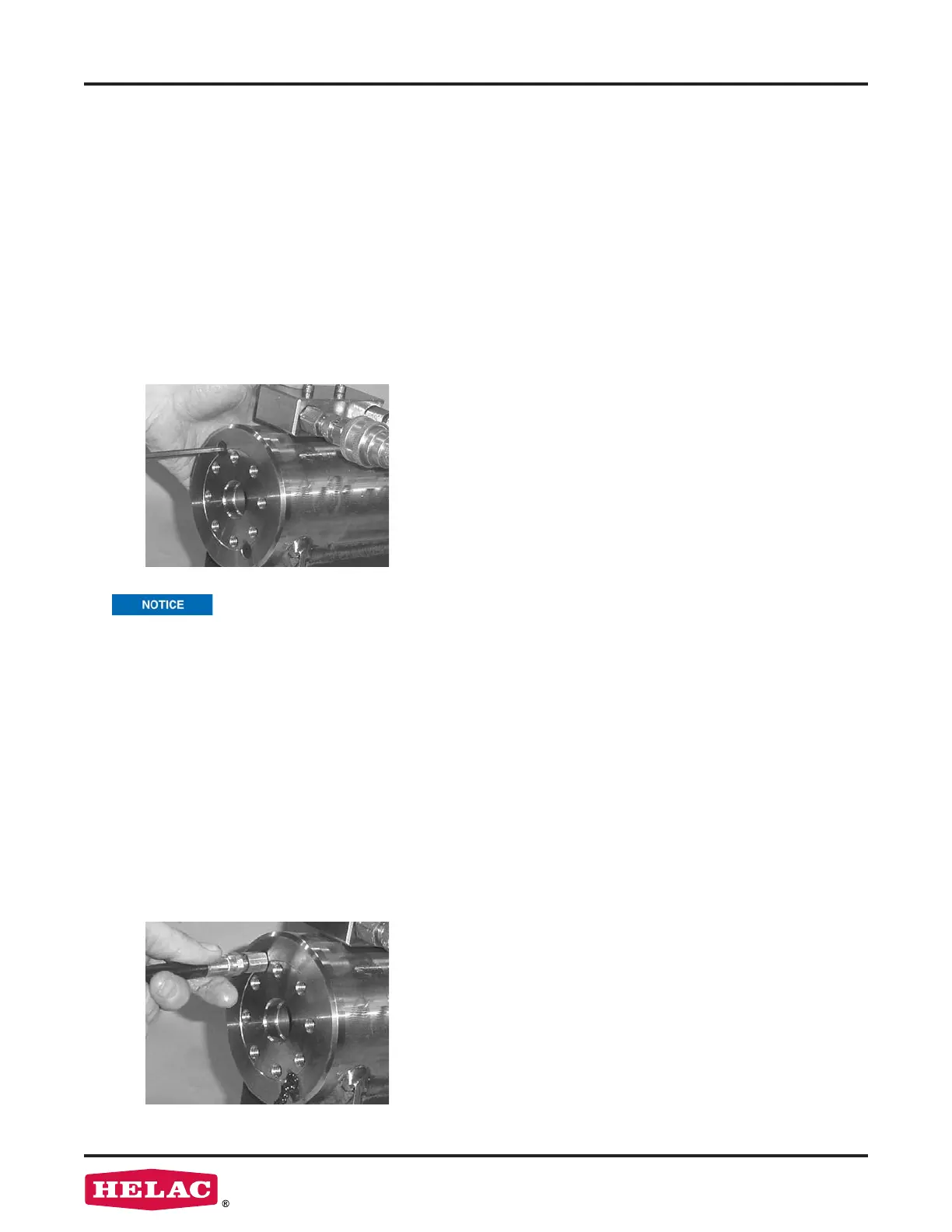

1. After the actuator is assembled but before

it is put into service, the thrust washer

area must be packed with Lithium grease.

There are two grease ports located on

both the shaft ange and the end cap.

They are plugged with cap screws (113)

or set screws. Remove the grease port

screws from the shaft ange and end cap.

(See exploded view on page 9)

If a hydraulic test bench is not

available, the actuator can

be rotated by hand, open the

pressure ports and use a pry

bar with cap screws inserted

into the shaft ange to turn the

shaft in the desired direction.

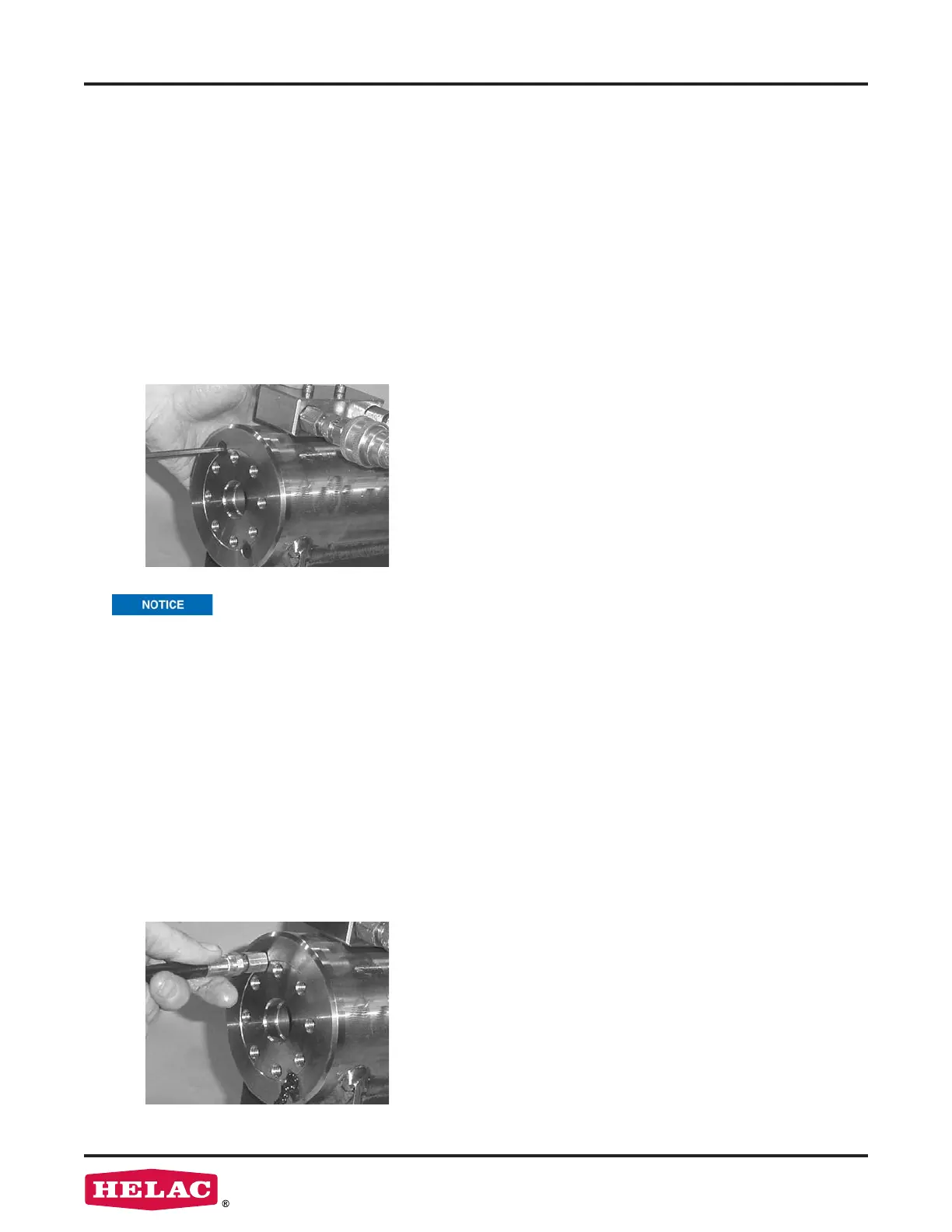

Insert the tip of a grease gun into one

port and apply grease to the shaft ange.

Continue applying until grease ows from

the opposite port. Cycle the actuator ve

times and apply grease again. Repeat this

process on the end cap. Insert the cap

screws into the grease ports and tighten

to 25 in-lbs. (2.8 Nm).

Greasing Thrust Washers

Loading...

Loading...