23

Parker Hannifin Corporation

Helac/Cylinder Division

Enumclaw, Washington USA

www.helac.com

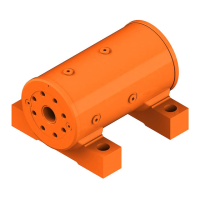

Helical, Hydraulic Rotary Actuators

L20 Series Service & Repair Manual

Catalog HY34-1120

Testing the Actuator

If the equipment is available, the actuator

should be tested on a hydraulic test bench.

The breakaway pressure — the pressure at

which the shaft begins to rotate — should

be approximately 500 psi (34 bar). Cycle the

actuator at least 25 times at 3000 psi (207 bar)

pressure. After the 25 rotations, increase the

pressure to 4500 psi (315 bar) to check for

leaks and cracks. Perform the test again at the

end of the rotation in the opposite direction.

Testing the Actuator for

Internal Leakage

If the actuator is equipped with a

counterbalance valve, plug the valve ports.

Connect the hydraulic lines to the housing

ports. Bleed all air from the actuator (see

Installation and Bleeding on page 24) Rotate

the shaft to the end of rotation at 3000 psi

(207 bar) and maintain pressure. Remove the

hydraulic line from the non-pressurized side.

Continuous oil ow from the open housing

port indicates internal leakage across the

piston. Replace the line and rotate the shaft

to the end of rotation in the opposite direction.

Repeat the test procedure outlined above

for the other port. If there is an internal leak,

disassemble, inspect and repair.

Avoid personal injury and

machinery damage:

Read the Service and Repair Manual

for proper installation, maintenance

and repair procedures.

Spraying fluids.

Contents under pressure.

Wear approved eye protection.

Use caution when removing

port plugs and fittings.

To avoid contamination

to machined parts:

Make sure work area is clean.

To avoid injury or damage

to product:

Secure product to slotted table or vise.

Testing the Actuator

Loading...

Loading...