5

Parker Hannifin Corporation

Helac/Cylinder Division

Enumclaw, Washington USA

www.helac.com

Helical, Hydraulic Rotary Actuators

L20 Series Service & Repair Manual

Catalog HY34-1120

Operation Technology

Operation Technology

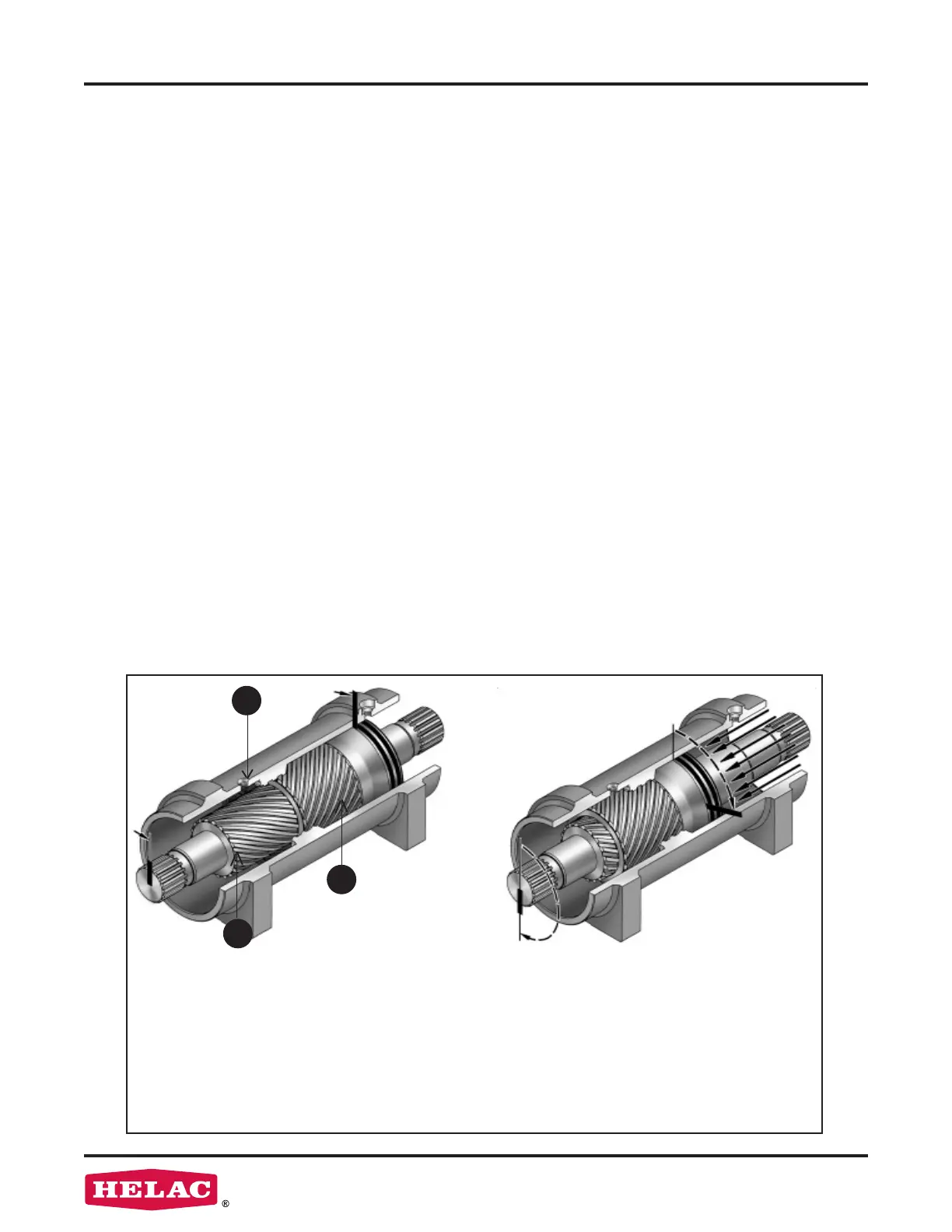

The L20 Series rotary actuator is a simple

mechanism that uses Helac's sliding spline

technology which converts axial piston motion

into powerful shaft rotation. As seen in the

illustration below left, each actuator is composed

of a housing with an integral ring gear (1) and

only two moving parts: the central shaft (2),

and the annular piston sleeve (3). Note the L20

actuator shaft features an integral mounting

ange and bearing which are not shown in the

illustration.

Helical spline teeth machined on the shaft

engage matching splines on the inside diam-

eter of the piston. The outside diameter of the

piston carries a second set of splines, of opposite

hand, which engage the matching splines of the

housing's ring gear.

As hydraulic pressure is applied, the piston is

displaced axially within the housing - similar

to the operation of a hydraulic cylinder - while,

simultaneously, the splines cause the shaft to

rotate. When the control valve is closed, oil is

trapped inside the housing, preventing piston

movement and locking the shaft rmly in position.

The shaft is supported radially by the large upper

radial bearing and the lower radial bearing (see

drawings on pages 8 and 9). Axially, the shaft

is separated from the housing by the upper and

lower thrust washers. The end cap is adjusted

for axial clearance and locked in position by set

screws or pins.

The L20 Series is available in several dierent

sizes. All L20 Series actuators have the same

internal design and basic components, though

congurations of parts may be slightly dierent

depending on model.

Many L20 actuators are equipped with factory

installed counterbalance valves, which perform

four major functions.

• Protects the actuator in the event of overload

• Enables the actuator to hold position without

drifting when external loads are applied

• Reduces hydraulic backlash by pressuring

the hydraulic uid

• Provides a constant controlled rate of rotation

in over-center load conditions

Bars indicate starting positions of piston

and shaft. Arrows indicate direction they

will rotate. The housing with integral ring

gear remains stationary. For clarity, the

shaft ange, bearings, and end cap are not

shown.

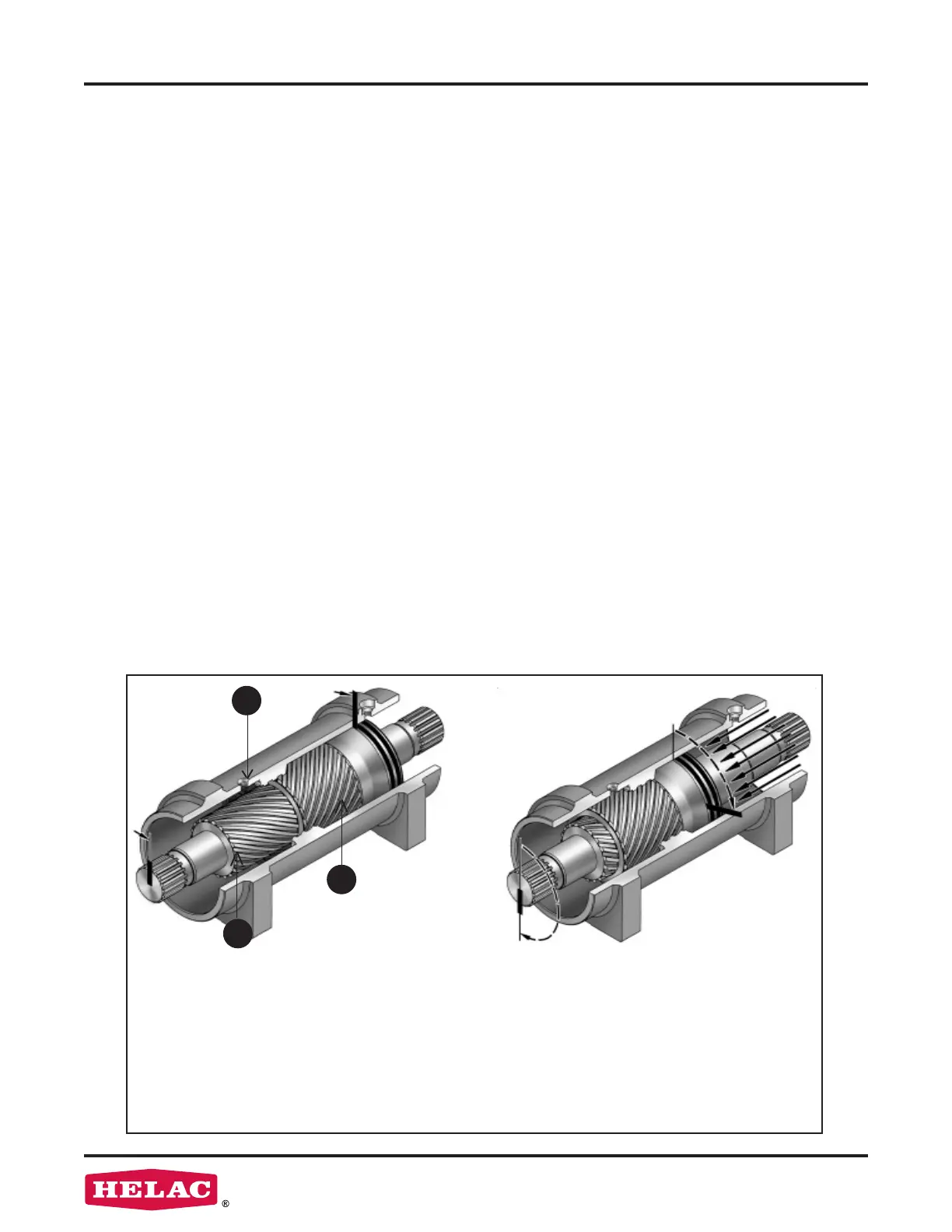

Applying uid pressure will displace the

piston axially while the helical gearing causes

the piston and shaft to rotate simultaneously.

The double helix design compounds rotation:

shaft rotation is about twice that of the piston.

Applying pressure to the opposite port will

return the piston and shaft to their original

starting positions.

3

2

1

Loading...

Loading...