6

T72007 A

HXL5

®

HUB MAINTENANCE PROCEDURES

ADB HUB AND ROTOR

For air disc brake (ADB) systems, the caliper must

be removed before removing the hub and rotor

assembly� ADB rotor and caliper mounting is dened in

Hendrickson literature number T71004 Hub and Rotor

Assembly and Caliper Mounting Procedures� Original

mounting hardware must be discarded, once removed,

and replaced with new hardware during reassembly�

Procedures for service and repair of Hendrickson’s

MAXX22T™ ADB can be found in Hendrickson literature

number T72009� For component replacement and

repair of ADB systems and rotors manufactured by other

vendors, links to Bendix, ConMet, Haldex and Wabco

literature is available at

www�hendrickson-intl�com/TrailerLit�

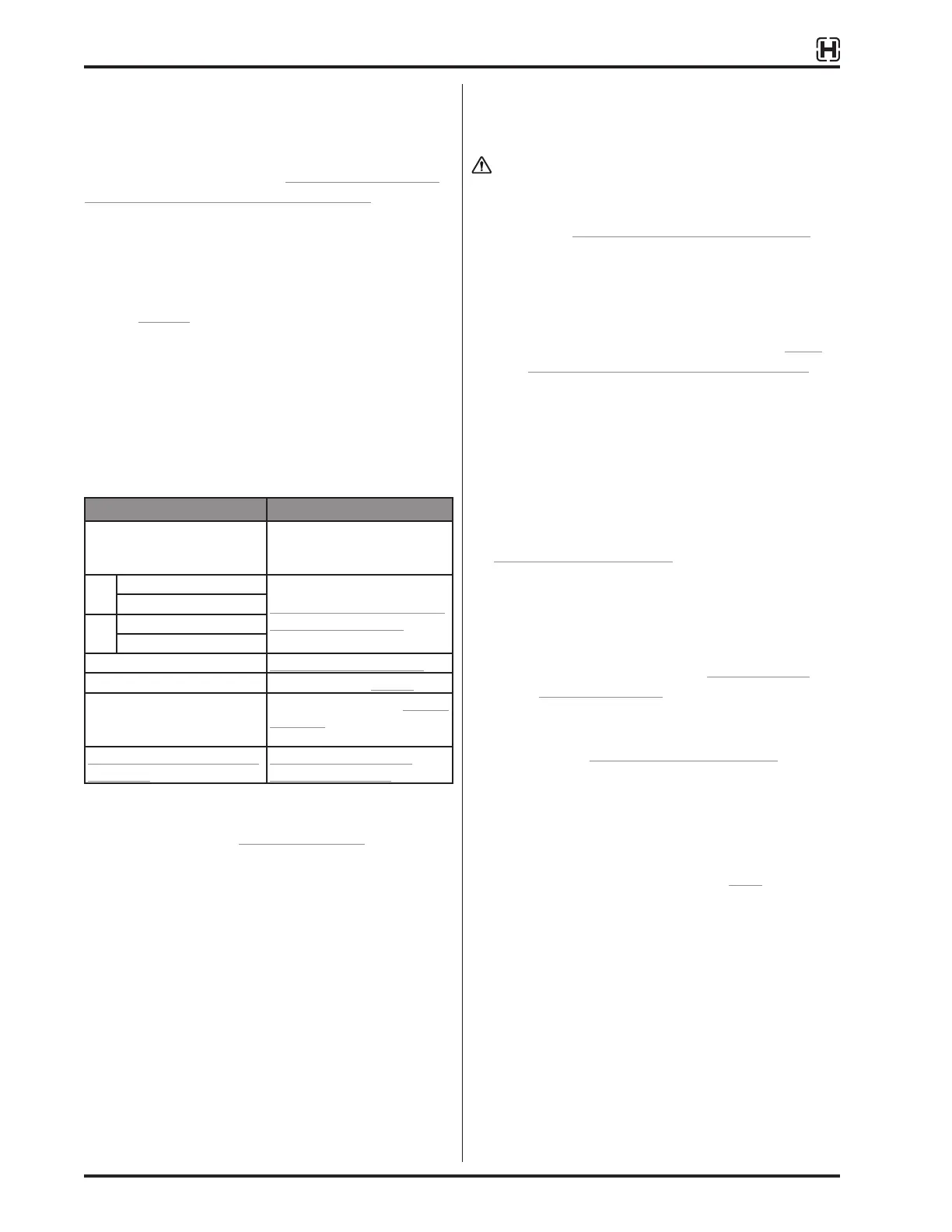

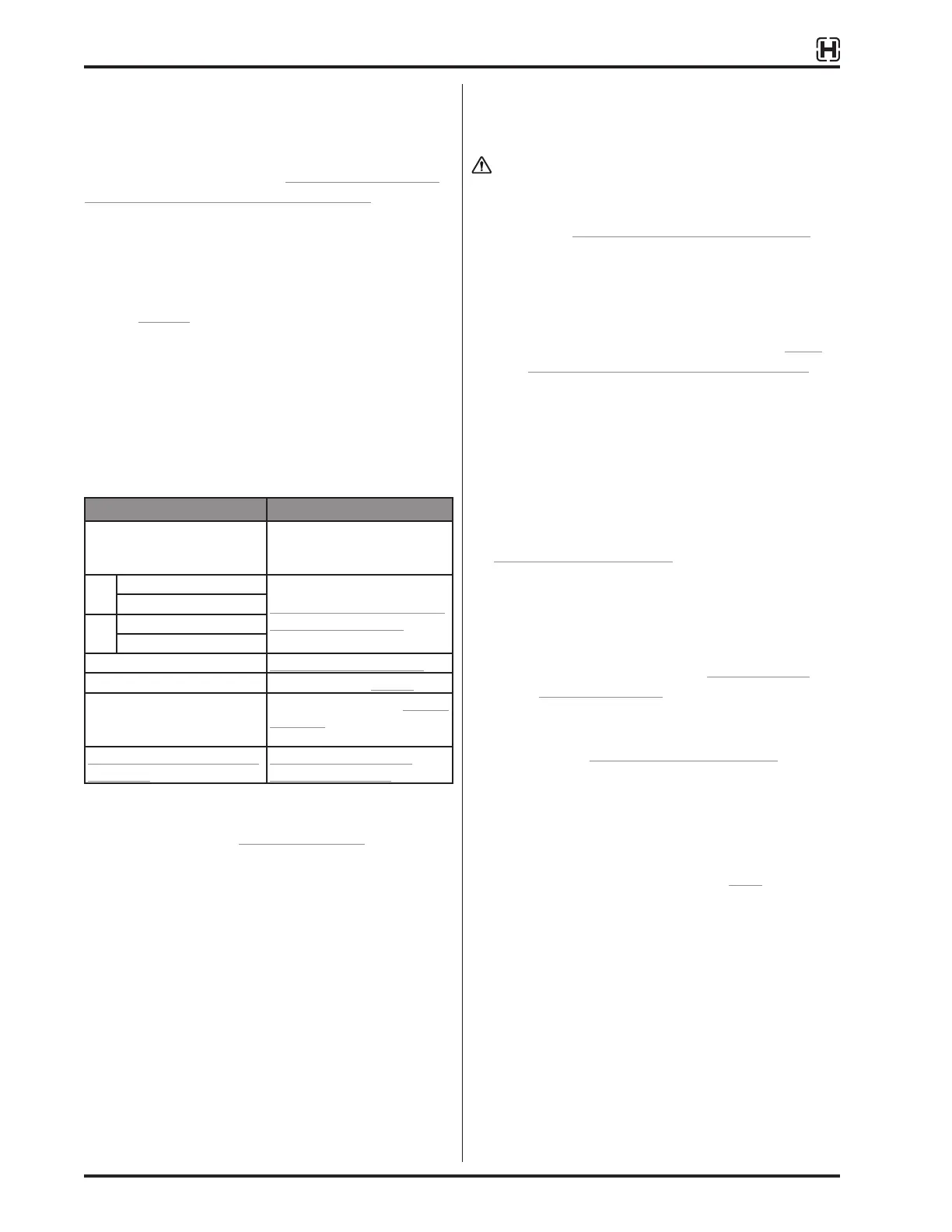

TOOLS REQUIRED

The following tools may be required during the

performance of some maintenance procedures:

TOOL WHERE USED

Torque Wrench

(10 - 200 ft� lbs� or

13 - 271 Nm)

To be used with sockets listed in

this table�

HN

3

13

/

16

inch socket

INSTALLING PRECISION SPINDLE

NUT SYSTEM on page12

5

/

32

inch hex key

HP

4

7

/

8

inch socket

3

/

16

inch hex key

1

/

2

inch socket INSTALL HUBCAP on page13

1

/

4

or

5

/

16

inch hex key Lube ll port plug (Figure 1)

Dial Indicator, with mounting

stand (resolution to 0�0001",

0�002 mm)

End-play measurement (Figure 4

on page8)

HUB SF GREASE DAM TEMPLATE

on page15

HUB AND OUTER BEARING

ASSEMBLY on page11

Table 2: List of required tools

IMPORTANT: Torque (Table 3 on page14) cannot

be properly applied with an ordinary

wrench� A calibrated torque wrench must

be used to tighten fasteners to specied

values�

INSPECTION

At regular intervals, the HXL5

®

hub assembly should be

checked for seal leaks and smooth rotation�

WARNING: Prior to performing inspection

procedures, help ensure conditions

are safe by following section

PREPARING TRAILER FOR SERVICE.

NOTE: Recommended inspection intervals are based

on an average trailer usage of 100,000

miles (160,000 km) per year� Higher usage

would require more frequent inspections�

Refer to Hendrickson literature number L578

Suspension Preventive Maintenance Guide for

more details�

Inspections should be performed:

• Daily pre-operation check� This would include a

general walk around to check for signs of obvious

damage, wear or other abnormalities�

• Every month, visually inspect back of the hub and

the hubcap for leakage� Refer to the section titled

CHECKING FOR SEAL LEAKS for complete inspection

details�

• Every three to four months:

− Perform monthly inspection�

− Check for smooth rotation�

» Refer to the section titled CHECKING FOR

SMOOTH ROTATION for details�

» If assistance is required or the hub feels

rough, sounds noisy or does not rotate freely,

refer to CONTACTING HENDRICKSON Technical

Services department for further assistance�

• During brake service - at this time, wheels are

removed making it easy to perform quarterly

inspections�

Refer to Hendrickson literature number L578 for

additional recommended suspension inspection

procedures�

Loading...

Loading...