9

T72007 A

HXL5

®

HUB MAINTENANCE PROCEDURES

A� If checking end play after installation, return to

INSPECTING HUB INSTALLATION on page13,

Step3�

B� If end play is more than 0.005” (0�127mm)�

Refer to CONTACTING HENDRICKSON Technical

Services for guidance on required next steps�

IMPORTANT: DO NOT place the suspension back into

service without correcting the problem�

C� If end play is within specication, no bearing

adjustment is necessary� Refer to Figure 13 on

page12 and check to ensure:

i� Spindle nut is secure�

ii� Interlock and tang are properly seated�

iii� Retaining screws are securely in place�

11� If not already done so, perform CHECKING FOR SEAL

LEAKS on page7�

12� Go to INSTALL HUBCAP on page13�

13� Reassemble brake wheel-end components�

REMOVING AND INSTALLING HUB

IMPORTANT: To ensure continued warranty, DO

NOT perform the following procedures

without obtaining prior authorization

from Hendrickson Trailer Technical

Services� Refer to CONTACTING

HENDRICKSON for contact information�

NOTE: In order to maintain warranty status,

CONTACTING HENDRICKSON is recommended

before removing the hubcap and disturbing the

precision spindle nut�

WARNING: Prior to performing maintenance

procedures, help ensure conditions

are safe by following section

PREPARING TRAILER FOR SERVICE on

page5.

HUB REMOVAL

Only after receiving proper authorization from

Hendrickson Technical Services, use the following

procedure to remove the HXL5

®

hub assembly:

1� Remove tire / wheel assembly�

2� Disengage brakes and:

If drum brake, remove brake drum�

If ADB equipped, remove the caliper�

3� Remove hubcap screws and remove hubcap,

discard gasket�

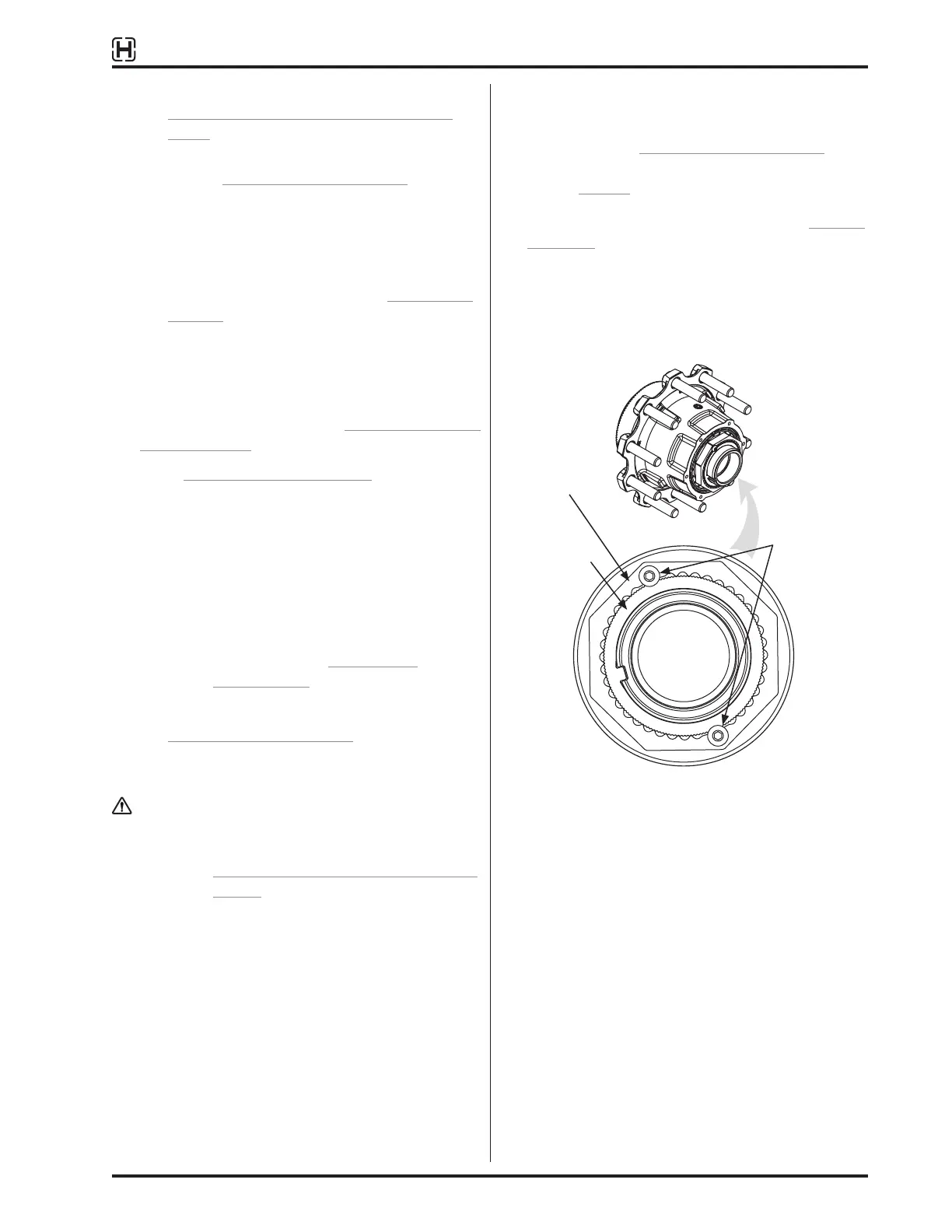

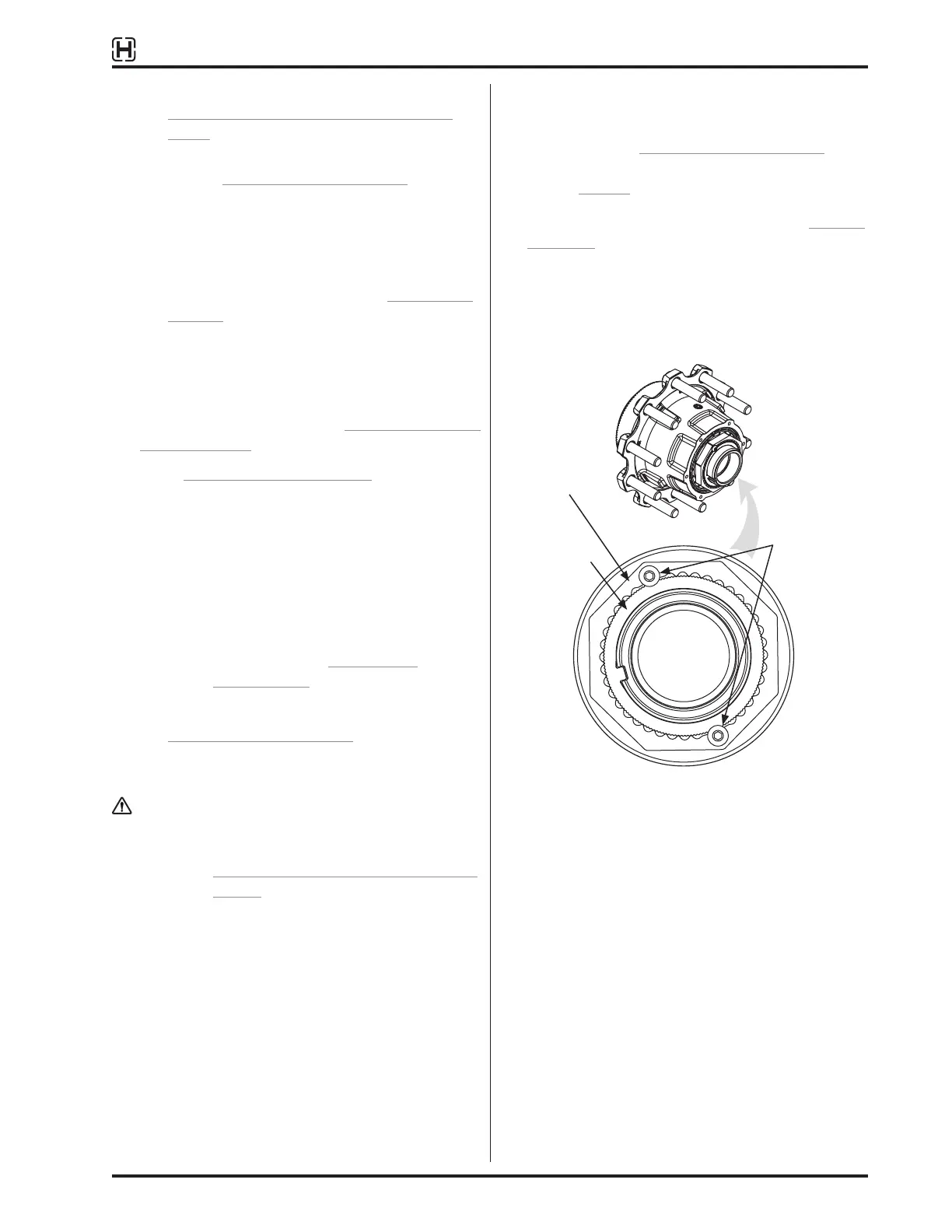

4� Using a hex key (TOOLS REQUIRED on page6),

remove button-head cap screws from interlock

washer Figure 7�

5� Remove interlock washer and spindle nut (Figure 1

on page5)�

NOTE: Pushing on edge of interlock washer near one

of the screw holes will cause the opposite edge

to tip away from the nut, allowing easy removal

of interlock washer�

Figure 7: Button-head cap screw on PRECISION240

®

or

PRECISION320

®

nut system

6� Carefully pull HXL5

®

hub assembly slightly toward

spindle end� A short quick motion should allow

outer bearing to exit the hub� Be prepared to catch

outer bearing if it slides off the end of the spindle�

Otherwise, simply remove it�

7� Remove hub from spindle. The inner bearing is

held in the hub by the hub seal and should come

off with the hub�

8� Remove and DISCARD HUB SEAL:

A� If the seal is in the hub - a pry bar can be

used to carefully remove the seal from the hub

bore� Damage to hub and hub surfaces must

be avoided�

Button-head cap

screw

Interlock washer

PRECISION240

®

or

PRECISION320

®

spindle nut

Loading...

Loading...