7

T72007 A

HXL5

®

HUB MAINTENANCE PROCEDURES

CHECKING FOR SEAL LEAKS

The HXL5 hub assembly is lled with Chevron Delo®

Synthetic Grease SF at the factory during the

manufacturing process� The grease is contained in the

hub by the hub seal where leakage can occur (Figure 1

on page5)�

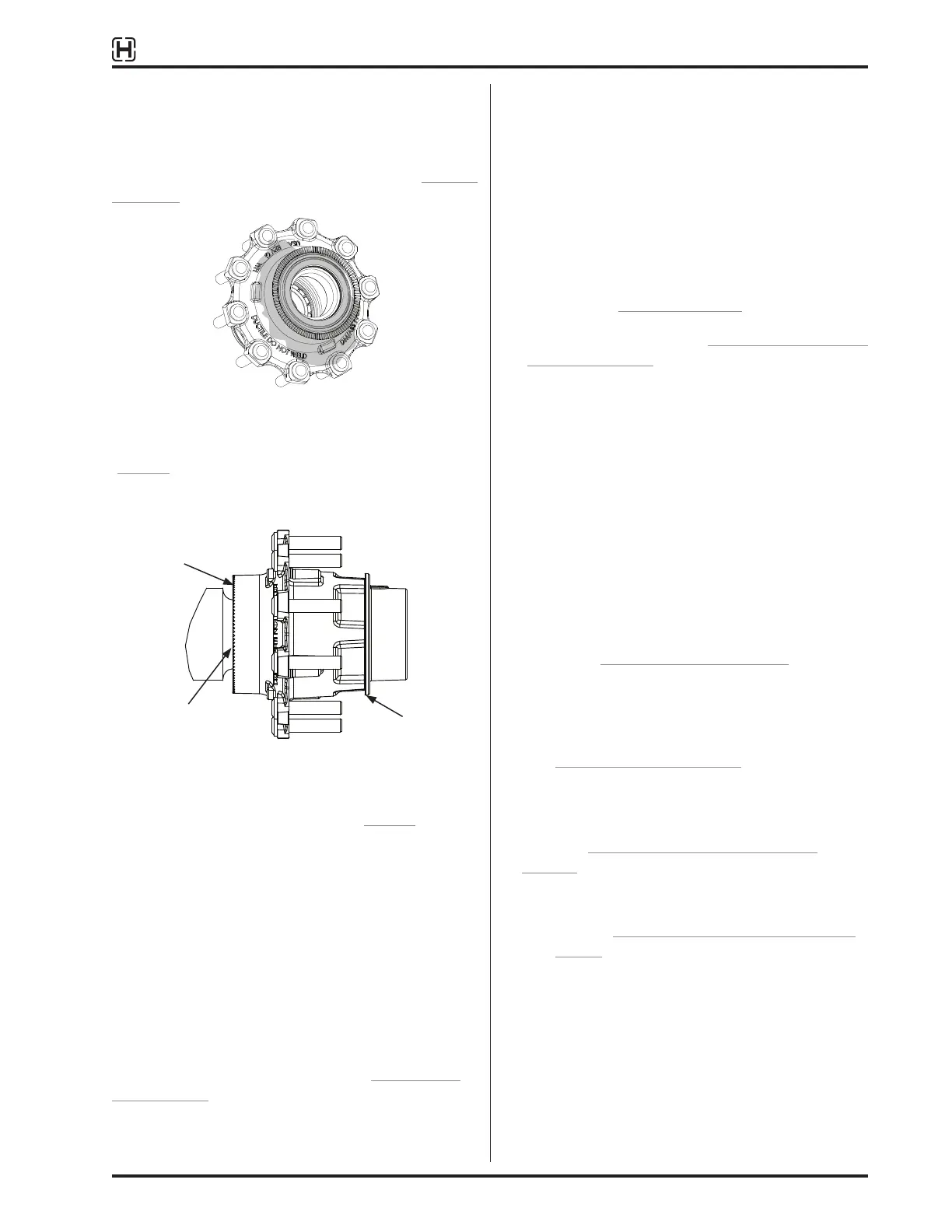

Figure 2: Check back side of hub for grease seal leak

To check for leaks, look at the inboard side of the hub,

(Figure 2)� A small amount of grease may be visible at

the hub seal� This is a normal occurrence and does

not necessarily indicate a seal leak� Wipe clean�

Hub seal

Spindle seal

journal

Hubcap

gasket

Outboard

side

Inboard

side

Figure 3: Areas where leaks may occur

A small amount of grease may also appear at the

spindle bearing shoulder to hub joint (Figure 3) This

is also normal and does not necessarily indicate a

seal leak� It should be wiped clean to minimize any

accumulation of dirt�

NOTICE: Pressure or steam washing should be

avoided in this area as water could

be forced past the seal and degrade

lubricant performance and corrode

bearings.

If the hub seal is leaking, a large quantity of grease will

be present in the areas of the hub, spindle hubcap and

wheel� If you see this condition, refer to CONTACTING

HENDRICKSON Technical Services for guidance on how

to proceed�

CHECKING FOR SMOOTH ROTATION

Many factors can effect smoothness of rotation� Primary

causes include:

• Bearing wear

• Damaged hub seal

• Debris

NOTE: A reasonable assessment can be performed

without removing tires and rims� However, this

procedure is best performed with hub only as

shown in Figure 5 on page8�

1� Ensure trailer is secure per PREPARING TRAILER FOR

SERVICE on page5�

2� Disengage brakes and remove brake drum

(recommended)�

3� While maintaining physical contact, slowly rotate

hub in both directions at least ve revolutions�

4� During rotation, ensure smooth and quiet rotation�

The bearings should move smoothly� Feel for any

resistance in movement� Any debris in bearings

should be felt as it moves over rollers in bearings�

IMPORTANT: If bearings feel rough, sound noisy or

DO NOT rotate freely, DO NOT place the

suspension back into service� Refer to

CONTACTING HENDRICKSON Technical

Services for guidance�

CHECKING END PLAY

This procedure must be performed:

• After CONTACTING HENDRICKSON Technical Services,

before removing the hubcap (as stated on hubcap

label), for guidance relative to suspected wheel end

play movement�

• As part of INSPECTING HUB INSTALLATION on

page13�

1� If not already done so:

A� Perform PREPARING TRAILER FOR SERVICE on

page5�

B� Remove wheel (tires and rims)�

C� Disengage brakes�

D� If drum brake, remove drum (recommended)�

If ADB, remove brake pads per manufacturer’s

recommended procedures�

E� Remove hubcap and discard gasket�

Loading...

Loading...