8

T72007 A

HXL5

®

HUB MAINTENANCE PROCEDURES

IMPORTANT: End play can be checked with brake

drum installed or removed (preferred)� If

installed, ensure all brake drum wheel

fasteners are installed and tightened

to manufacturers specications before

checking end play�

2� Ensure hub hubcap mounting surface and end of

spindle are clean and totally free of any burrs or

debris�

3� Rotate hub at least 5 revolutions to ensure

bearings are fully seated�

NOTE: The hub MUST be rotated before performing

end play measurement� Rotation works the

rollers into their fully seated positions against

the bearing cone shoulder� Failure to rotate

hub could result in a false end play reading�

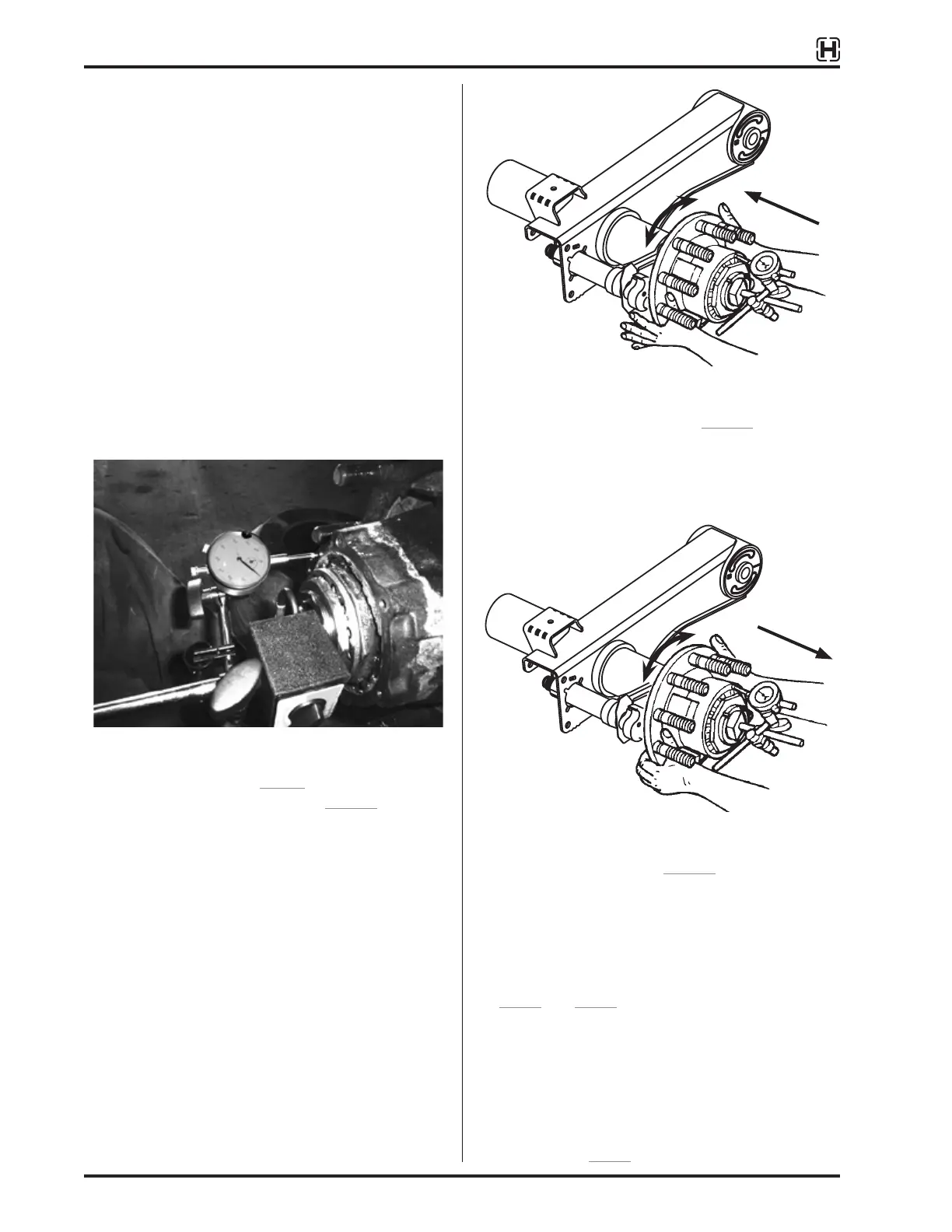

Figure 4: Checking end play

4� Attach dial indicator (Table 2) with magnetic base

to at surface at end of spindle (Figure 4)�

5� Adjust dial indicator so its pointer line of action is

parallel to spindle axis and touches hub’s hubcap

mounting surface� Ensure the plunger contacts

the hub on a surface that is smooth and fully

machined� Any regions with scratches, gouges or

non-cleanup should be avoided�

6� Check indicator for free movement in both

directions� Lightly push and pull on indicator arm

to verify plunger is free to move at least �005” in

each direction� If indicator bottoms out, readjust

until it is free to move �005” in both directions�

7� Zero indicator�

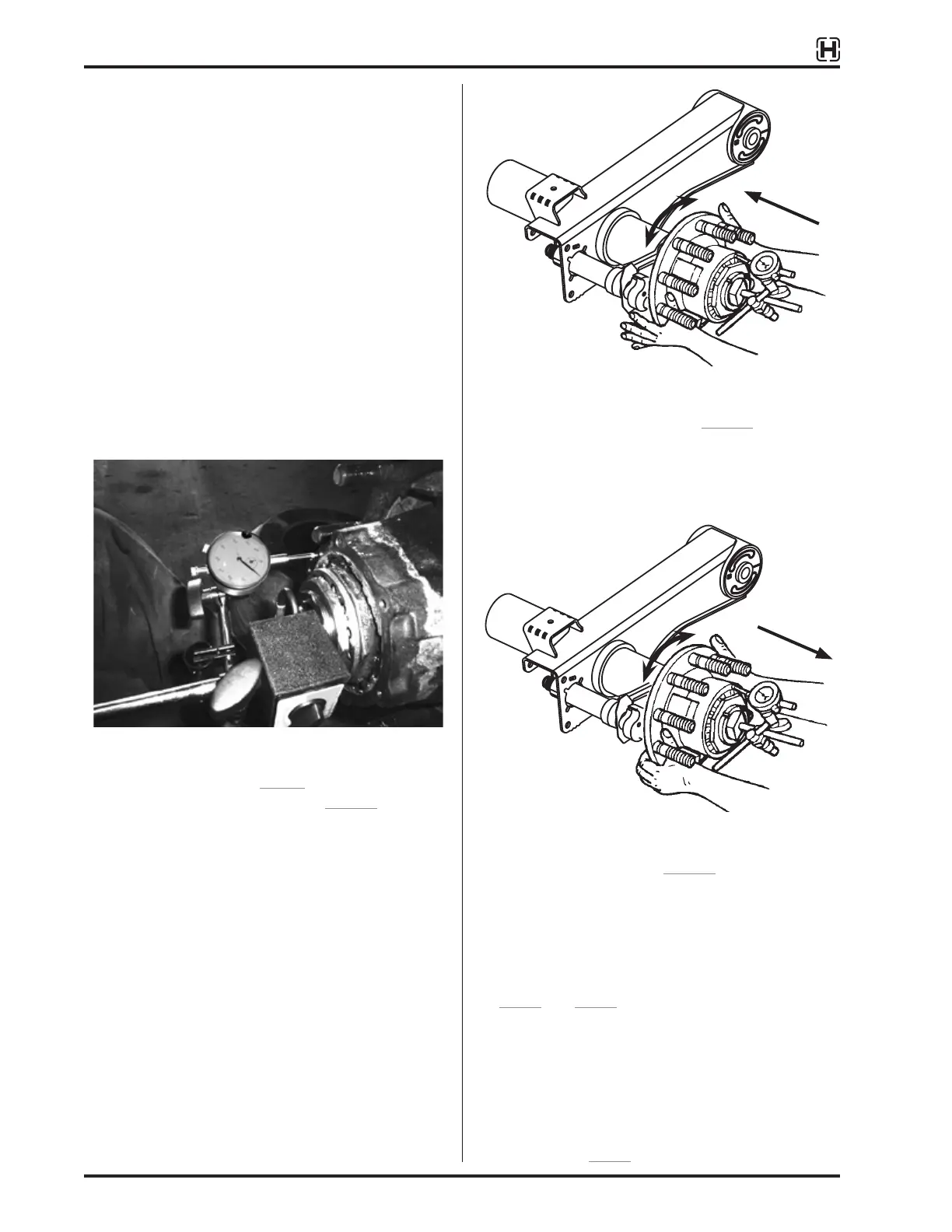

Rotate and

push hub

Figure 5: Checking inward end-play

8� Grasp hub ange, as shown in Figure 5, and push

the hub inward while rotating hub slightly in both

directions (15 - 30° between two holes) until the

dial indicator reading remains constant� Record

reading�

Figure 6: Checking outward end-play

9� While still grasping hub (Figure 6) pull hub outward

while rotating hub slightly in both directions (15 -

30° between two holes) until dial indicator reading

remains constant� Record reading�

10� End play is the total movement of the indicator�

Calculate difference between recorded values of

Step8 and Step9 to determine end play, record

value�

IMPORTANT: End play must be between 0�001”

(0�0254 mm) and 0�005” (0�0127 mm)�

If subsequent readings are necessary,

the hub must be rotated at least 5

revolutions to reseat the bearings (refer

to Step3)�

Rotate and

pull hub

Loading...

Loading...