Page 12 For technical questions, please call 1-888-866-5797. Item 59313

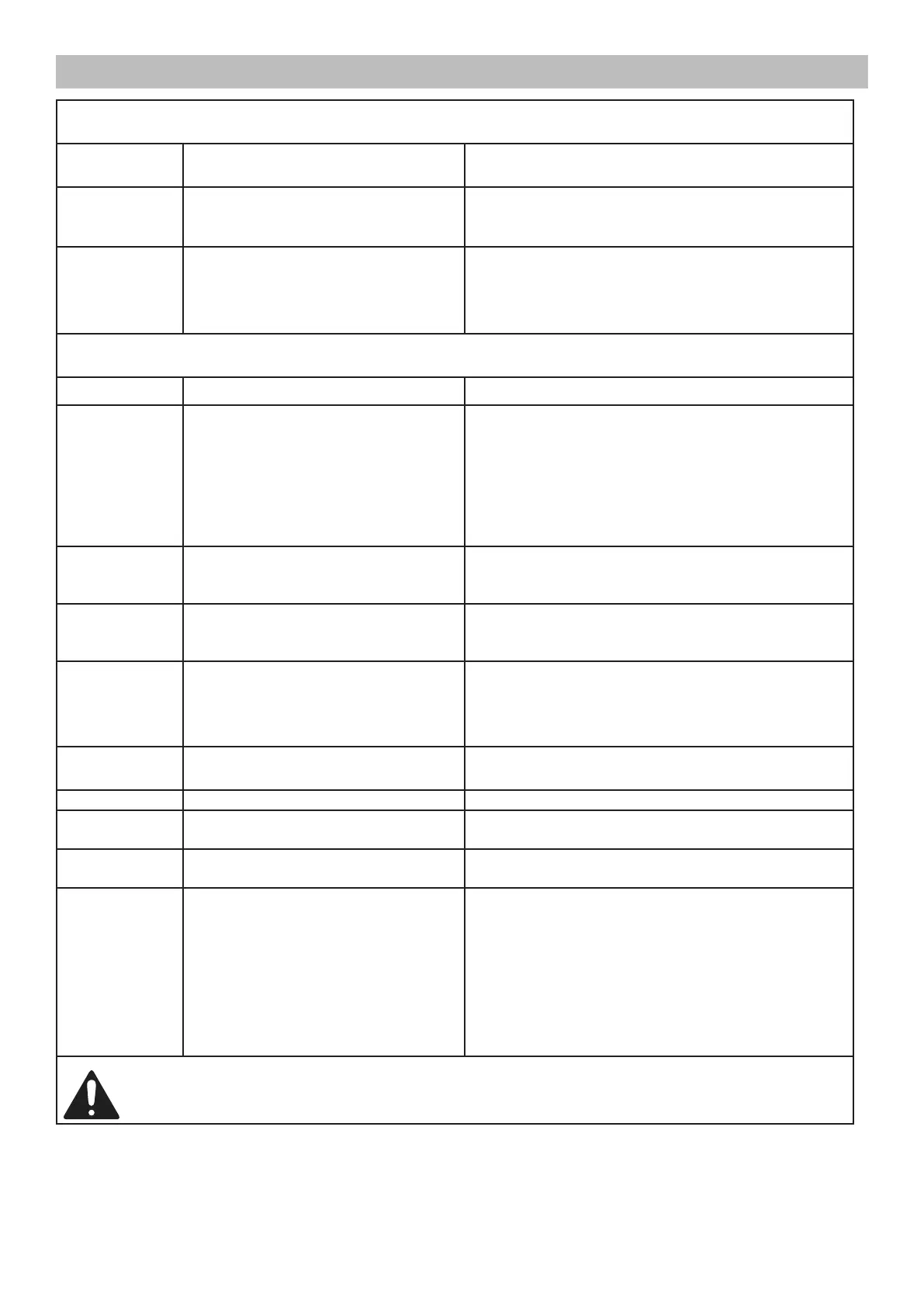

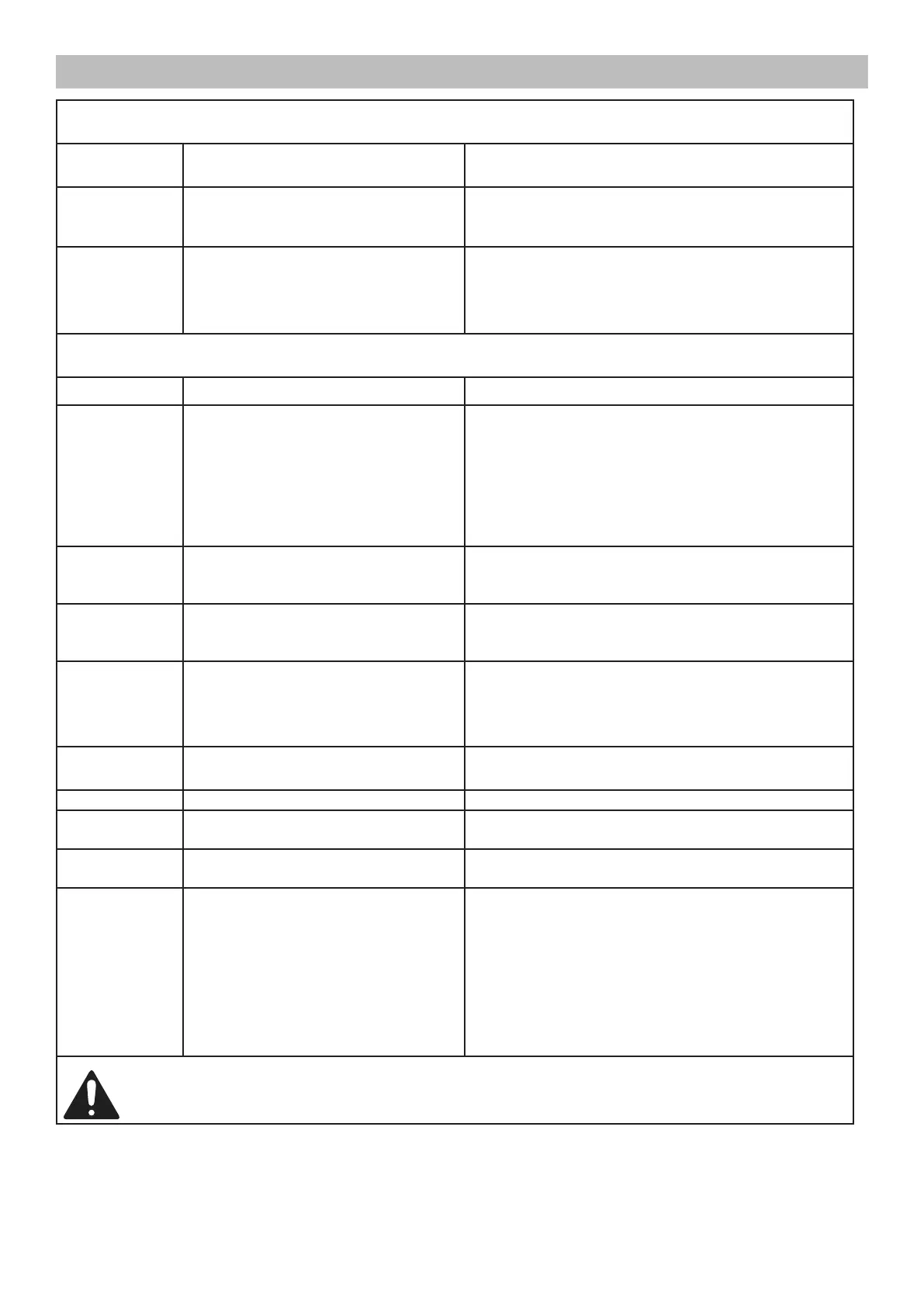

Troubleshooting

Workpiece

Problem Possible Causes Likely Solutions

Deeper cut at

ends of board

(snipe).

1. Too little support of long boards.

2. Uneven force on cutter head.

1. Provide better support for long boards.

2. Follow instructions according to

Correcting Snipe on page 11.

Torn, ragged,

rough or

raised grain.

1. Blades dull or damaged.

2. Cut is too heavy.

3. Blades cutting against grain.

4. Wood has a high moisture content.

1. Replace blades.

2. Reduce depth of cut.

3. Cut with grain.

4. Use dry wood.

Planer

Problem Possible Causes Likely Solutions

Tool will not start. 1. Cord not connected.

2. No power at outlet.

3. Internal damage or wear. (Carbon

brushes or switch, for example.)

1. Check that cord is plugged in.

2. Check power at outlet. If outlet is unpowered,

turn off tool and check circuit breaker.

If breaker is tripped, make sure circuit is right

capacity for tool and circuit has no other loads.

3. Have qualified technician service tool.

Tool operates

slowly.

Extension cord too long or

wire size too small.

Eliminate use of extension cord. If an extension cord

is needed, use one with the proper diameter for its

length and load. See Table A on page 2.

Performance

decreases

over time.

1. Blades dull or damaged.

2. Carbon brushes worn or damaged.

1. Replace blades.

2. Have qualified technician replace brushes.

Roller case

adjustment

difficult

1. Sprockets and/or chain dirty.

2. Elevating screws and/

or columns dirty.

3. Elevating screws worn.

1. Clean and lubricate sprockets and/or chain.

2. Clean and lubricate elevating

screws and/or columns.

3. Replace elevating screws.

Chain jumping 1. Sprockets worn.

2. Chain worn.

1. Have sprockets replaced.

2. Have chain replaced.

Belt Slipping Loose belt Replace belt.

Excessive

dust in air

Leaking bag or loose connection. Check connections or replace collection bag.

Excessive noise

or rattling.

Internal damage or wear. (Carbon

brushes, bearings, or fan for example.)

Have qualified technician service tool.

Overheating/

Circuit breaker

tripping.

1. Dull blades.

2. Forcing boards through planer.

3. Blade dull or damaged.

4. Cut is too heavy.

5. Motor being strained by long or

small diameter extension cord.

1. Replace blades.

2. Allow auto feed to work at its own rate.

3. Replace blades.

4. Reduce depth of cut.

5. Eliminate use of extension cord.

If an extension cord is needed, use one with

the proper diameter for its length and load.

See Table A on page 2.

Follow all safety precautions whenever diagnosing or servicing the tool.

Disconnect power supply before service.

Loading...

Loading...