Page 5For technical questions, please call 1-888-866-5797.Item 64855

h. Use extra caution when cutting a workpiece

that is twisted, knotted, warped or does

not have a straight edge to guide it with a

miter gauge or along the fence. A warped,

knotted, or twisted workpiece is unstable

and causes misalignment of the kerf with

the saw blade, binding and kickback.

i. Never cut more than one workpiece, stacked

vertically or horizontally. The saw blade could

pick up one or more pieces and cause kickback.

j. When restarting the saw with the saw

blade in the workpiece, center the saw

blade In the kerf so that the saw teeth are

not engaged in the material. If the saw

blade binds, it may lift up the workpiece and

cause kickback when the saw is restarted.

k. Keep saw blades clean, sharp, and with

sufficient set. Never use warped saw

blades or saw blades with cracked or broken

teeth. Sharp and properly set saw blades

minimize binding, stalling and kickback.

9. Table saw operating procedure warnings

a. Turn off the table saw and disconnect

the power cord when removing the table

insert, changing the saw blade or making

adjustments to the Riving Knife, anti-

kickback device or saw blade guard, and

when the machine Is left unattended.

Precautionary measures will avoid accidents.

b. Never leave the table saw running unattended.

Turn it off and don’t leave the tool until it

comes to a complete stop. An unattended

running saw is an uncontrolled hazard.

c. Locate the table saw in a well-lit and level

area where you can maintain good footing

and balance. It should be installed in an area

that provides enough room to easily handle the

size of your workpiece. Cramped, dark areas,

and uneven slippery floors invite accidents.

d. Frequently clean and remove sawdust

from under the saw table and/or the dust

collection device. Accumulated sawdust

is combustible and may self-ignite.

e. The table saw must be secured. A table saw

that is not properly secured may move or tip over.

f. Remove tools, wood scraps, etc. from the

table before the table saw is turned on.

Distraction or a potential jam can be dangerous.

g. Always use saw blades with correct size

and shape (diamond versus round) of

arbor holes. Saw blades that do not match

the mounting hardware of the saw will run

off-center, causing loss of control.

h. Never use damaged or incorrect saw blade

mounting means such as flanges, saw blade

washers, bolts or nuts. These mounting

means were specially designed for your saw,

for safe operation and optimum performance.

i. Never stand on the table saw, do not

use it as a stepping stool. Serious injury

could occur if the tool is tipped or if the

cutting tool is accidentally contacted.

j. Make sure that the saw blade is installed

to rotate in the proper direction. Do not use

grinding wheels, wire brushes, or abrasive

wheels on a table saw. Improper saw

blade installation or use of accessories not

recommended may cause serious injury.

Grounding

TO PREVENT ELECTRIC SHOCK AND

DEATH FROM INCORRECT

GROUNDING WIRE CONNECTION READ

AND FOLLOW THESE INSTRUCTIONS:

Grounded Tools: Tools with

Three Prong Plugs

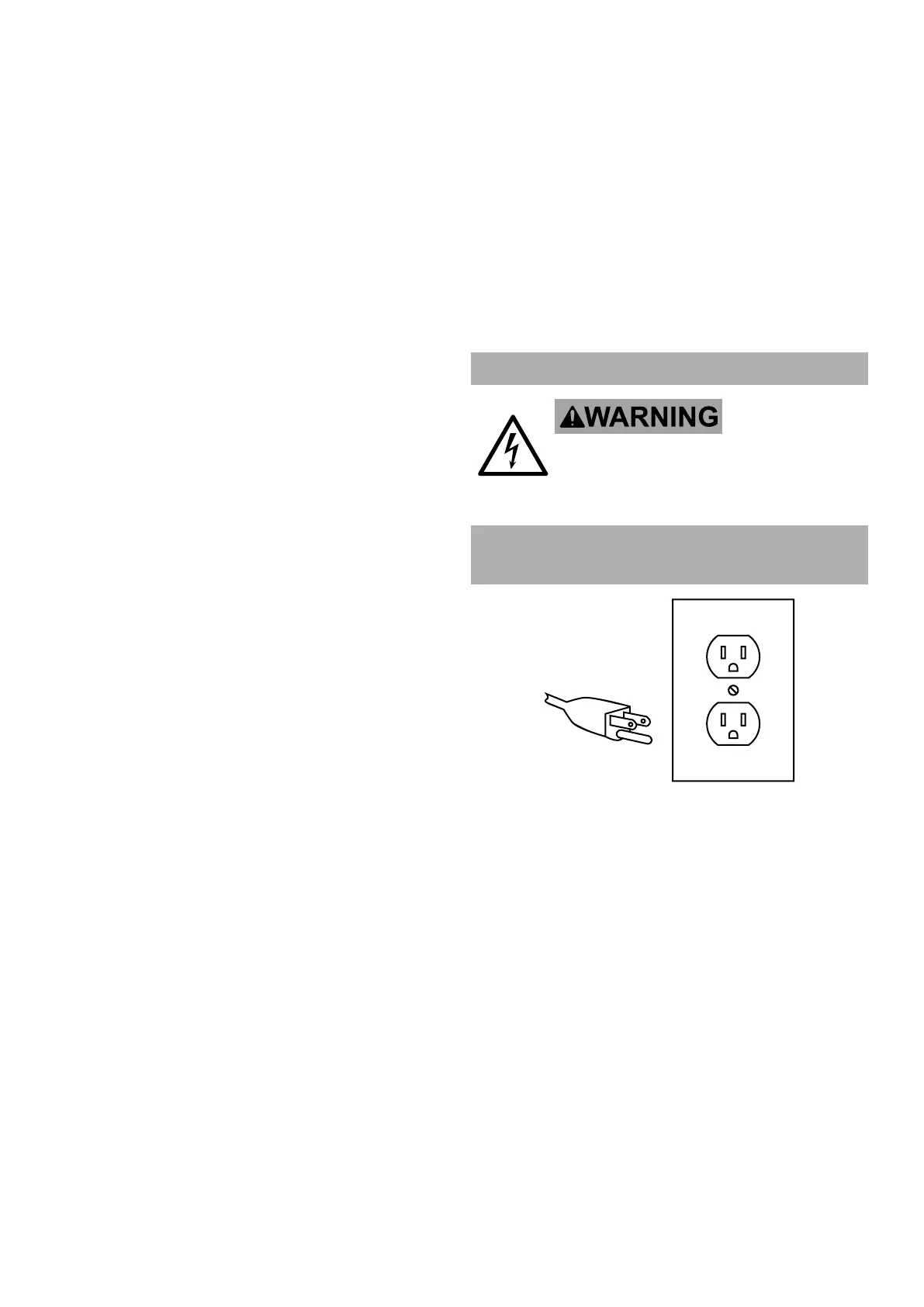

3-Prong Plug and Outlet

1. Tools marked with “Grounding Required” have a three

wire cord and three prong grounding plug. The plug

must be connected to a properly grounded outlet.

If the tool should electrically malfunction or break

down, grounding provides a low resistance path to

carry electricity away from the user, reducing the risk

of electric shock. (See 3-Prong Plug and Outlet.)

2. The grounding prong in the plug is connected through

the green wire inside the cord to the grounding

system in the tool. The green wire in the cord must

be the only wire connected to the tool’s grounding

system and must never be attached to an electrically

“live” terminal. (See 3-Prong Plug and Outlet.)

3. The tool must be plugged into an appropriate outlet,

properly installed and grounded in accordance with

all codes and ordinances. The plug and outlet should

look like those in the preceding illustration.

(See 3-Prong Plug and Outlet.)

Loading...

Loading...