27

Surface Roughness and Tipping

Because of the small penetration depth surface roughness of the material has relatively

strong influence on the measured data. Surface roughness in the category of plaster or

floor isn’t a serious problem, but for a reliable measurement surface roughness

shouldn’t be larger.

The area, where the sensing head has to be put onto, shouldn’t have too large

roughness and ledges. It could be better if the measurement would be repeated at a

smoother place. If such smooth places aren’t available then a mean value should be

generated from several single measurements. By calculation of the standard deviation

the reliability of the measurement can be checked.

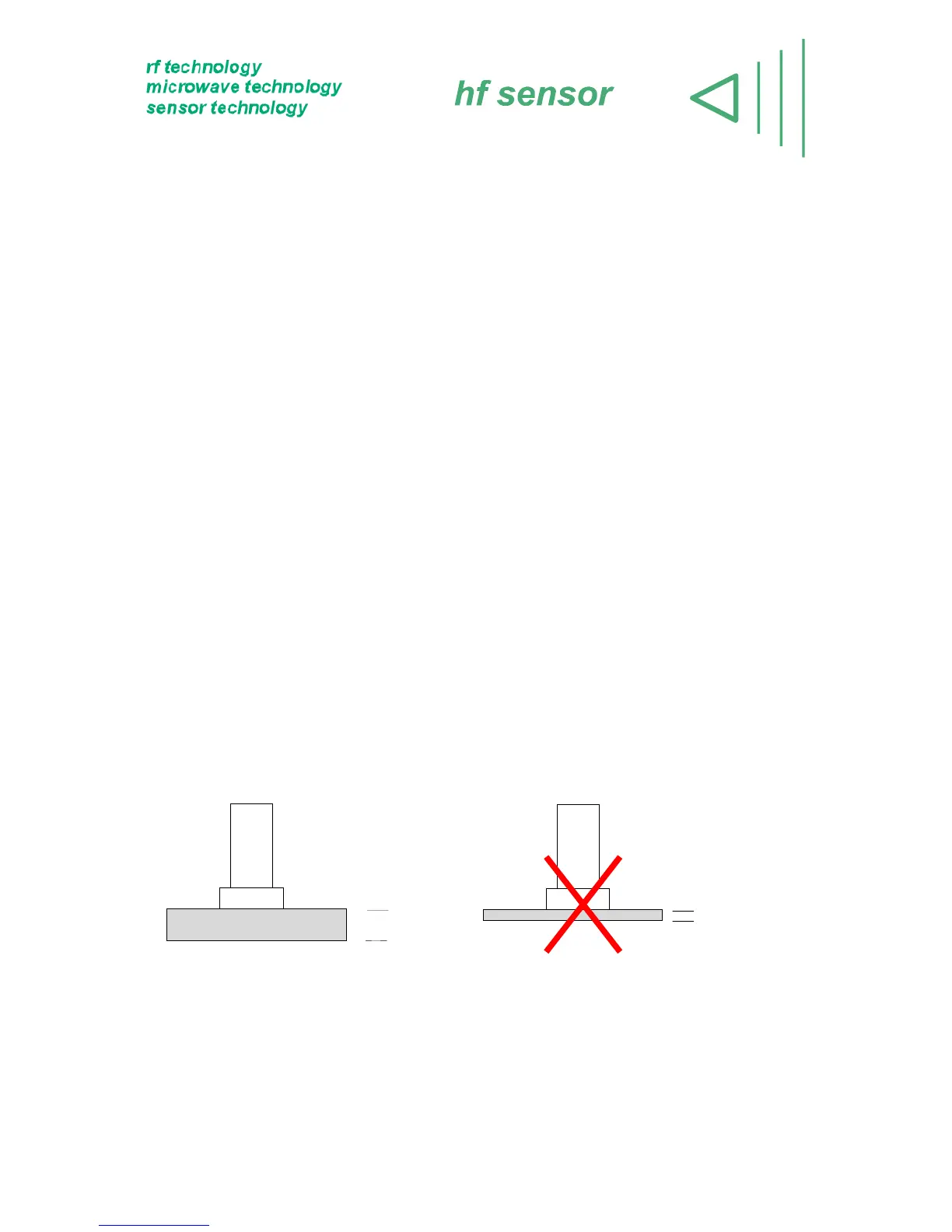

Take care during the measurement that the sensing head isn’t tipping. Even low

variations in the distance between the active microwave element and the surface of the

material, as they can be caused by tipping, may cause considerable falsification of the

measured values.

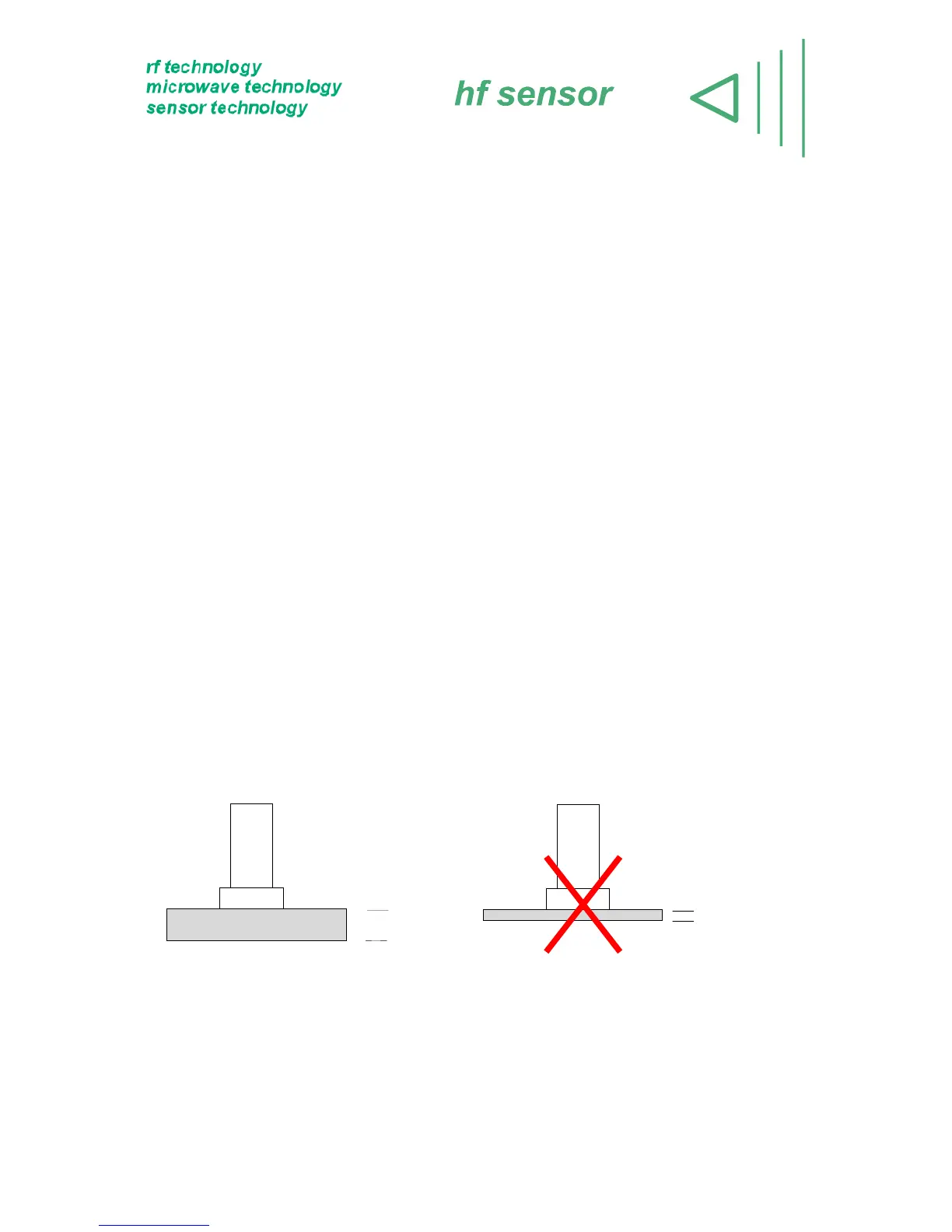

Minimum Thickness of Material

The field penetrates the material, depending on moisture and material type, in the range

of 1 ... 3 cm. Therefore test objects must have a minimum thickness in this range. If

material thickness is lower, the measurement can be falsified.

Moisture measurement with the surface sensing head MOIST-R1M V2 is also possible

in objects with lower thickness.

Before doing such a measurement hf sensor must be consulted, because usually

for such measurements special arrangements must be used.

> 1 ... 3 cm

< 1 cm

Loading...

Loading...