22 English

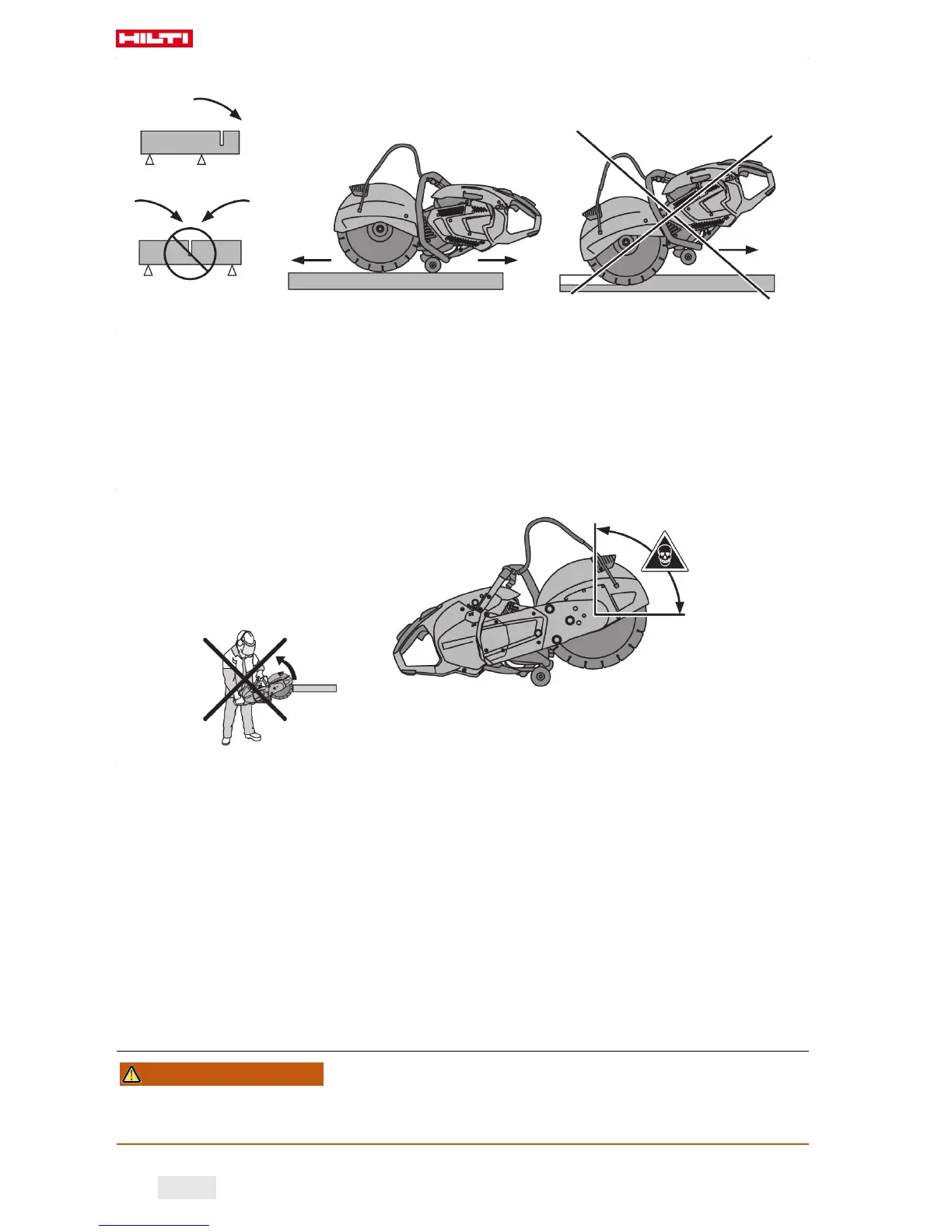

Reasons for the cutting disc stalling:

• The cut is too deep.

• The kerf closes (e.g. when cutting pipes or slabs).

• The cutting disc is off-square in the kerf.

• The cutting disc is unsuitable for the job (the cutting disc becomes clogged).

• The cutting disc is inserted too quickly into an existing kerf.

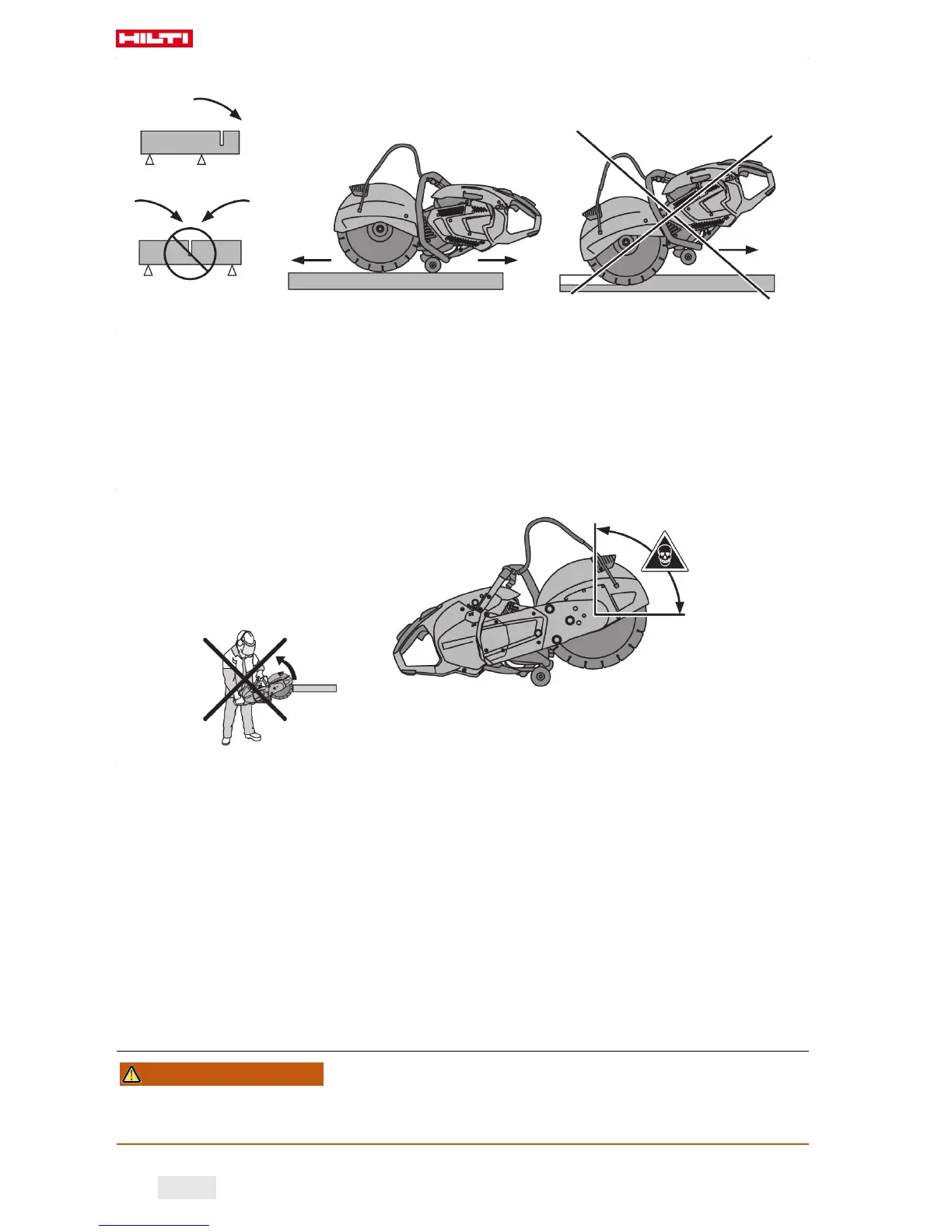

The hazardous situations that result from stalling differ, depending on the working position.

• Forward pull can occur when a horizontal cut is being made (e.g. in the ground). The saw suddenly

snatches forward, possibly pulling out of your hands.

• Climbing can occur when a vertical cut is being made (e.g. in a wall). The saw suddenly snatches upward,

possibly pulling out of your hands.

• Kickback can occur if the prohibited area of the disc is brought into contact with the workpiece.

To avoid the hazardous situations that result from stalling of the cutting disc:

▶

When cutting a thick workpiece, increase the depth of the kerf in steps. Avoid excessively deep cuts.

▶ Support slabs or large workpieces so that the kerf remains open during and after the cutting operation.

▶ Always bring the cutting disc into contact with the workpiece from above.

◁ Allow the cutting disc to contact the workpiece only at a point below the rotational axis of the disc.

▶ Take great care when guiding the cutting disc into an existing kerf.

▶ Do not tilt the cutting disc in the kerf.

7 Care and maintenance

WARNING

Risk of injury. Touching the rotating cutting disc or hot parts of the machine may lead to injury or burns.

▶ Switch the engine off and allow the product to cool down before all maintenance, repairs, cleaning or

servicing.

Printed: 24.04.2018 | Doc-Nr: PUB / 5265931 / 000 / 02

Loading...

Loading...