To avoid injury, turn the switch OFF and disconnect the

saw from the power source before making any

adjustments. NEVER make tension adjustments with the

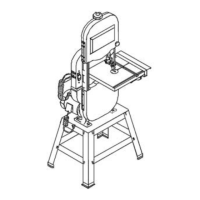

The gauge (1) on the bracket (2) at the rear of the upper

wheel housing indicates the proper tension for the

Set the blade tension gauge to correspond with the

width of the blade in use.

Turn the blade tension knob (3) clockwise, raising

the upper wheel to tighten the blade. Turn the knob

counterclockwise to lower the upper wheel,

3. As you become familiar with the saw, you may want

to change the tension settings.

Changes in blade width and type of material

being cut will have an effect on the blade tension.

Too much or too little tension could break the blade.

When the band saw is not in use, relax the blade

To avoid injury, turn the switch OFF and unplug the

saw from the power source before making any

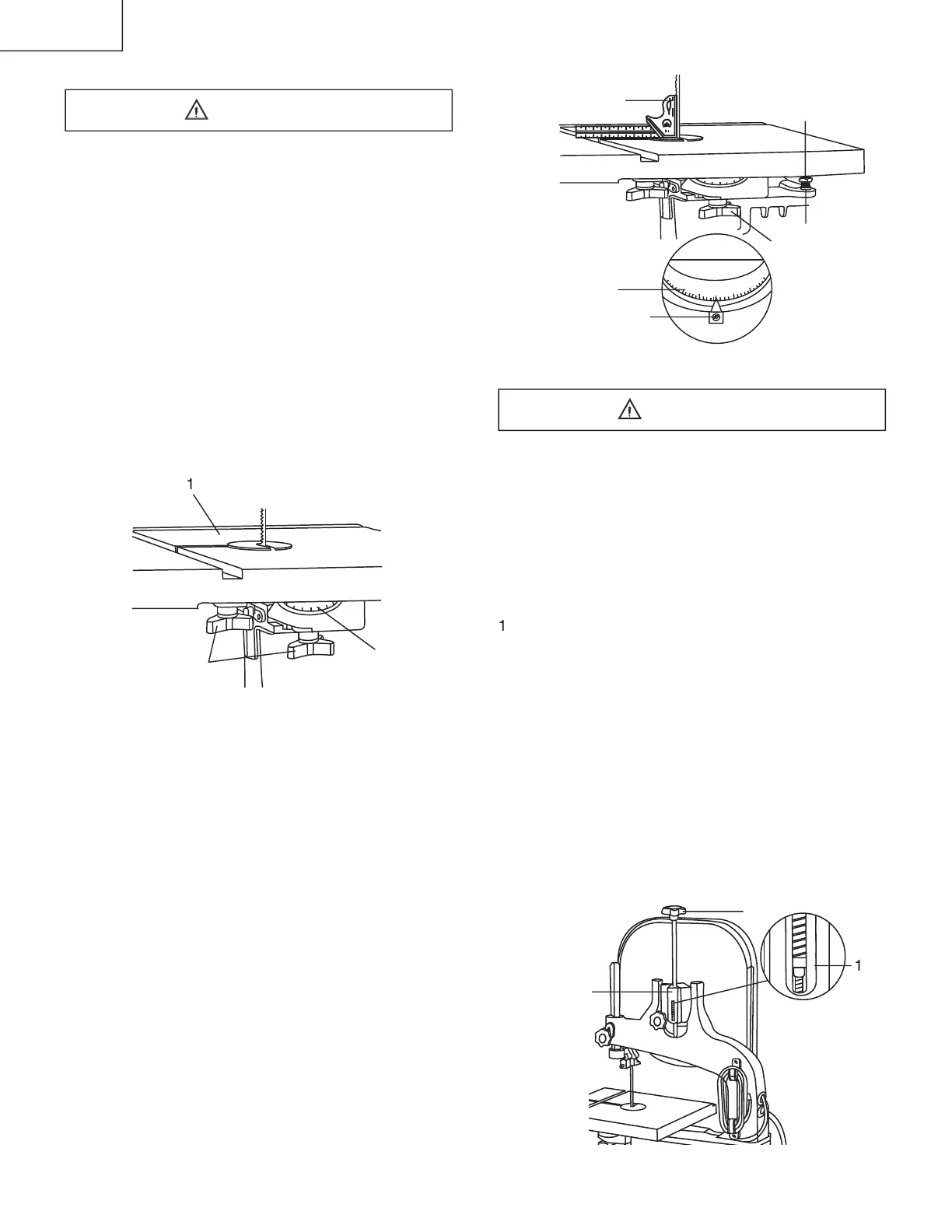

TABLE ADJUSTMENTS (FIG. J, K)

Tilting the table (Fig. J)

The band saw table (1) tilts 0° to 45° right

1. Loosen both table lock knobs (2) underneath the

2. Tilt the table to the desired angle on the scale (3)

3. Tighten the two table lock knobs.

ADJUSTING THE 90° TABLE STOP

1. Loosen the table lock knobs (2) and tilt the table to

2. Loosen the nut (4) on the table stop bolt (5) and

lower the stop bolt as far as possible.

3. Tilt the table until rests on the stop bolt.

4. Place a combination square (6) on the table with the

heel of the square against the saw blade

5. Adjust the tilt of the table left or right until it is 90°

to the blade. Make sure there is no space between

the square and the blade. Tighten the table lock

6. Adjust the table stop bolt up until it touches the table.

7. Loosen the lock knobs and see that the table is

resting on the stop bolt.

8. Check the square to make sure the table is still

square to the blade. If not, readjustment the stop

9. When the adjustment is accurate at 90°, align the

pointer (7) to 0° the scale (8).

Loading...

Loading...