10 / 18

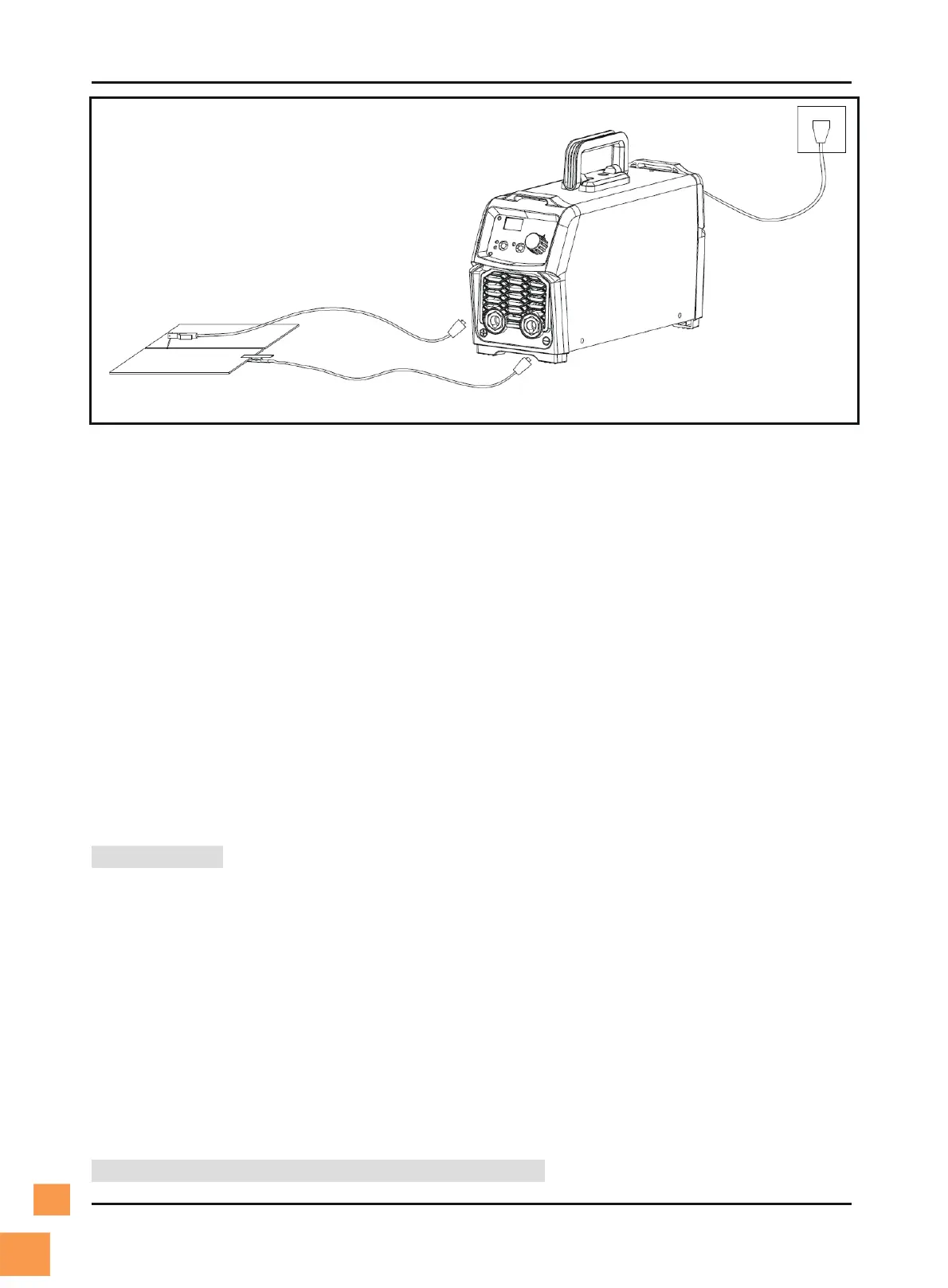

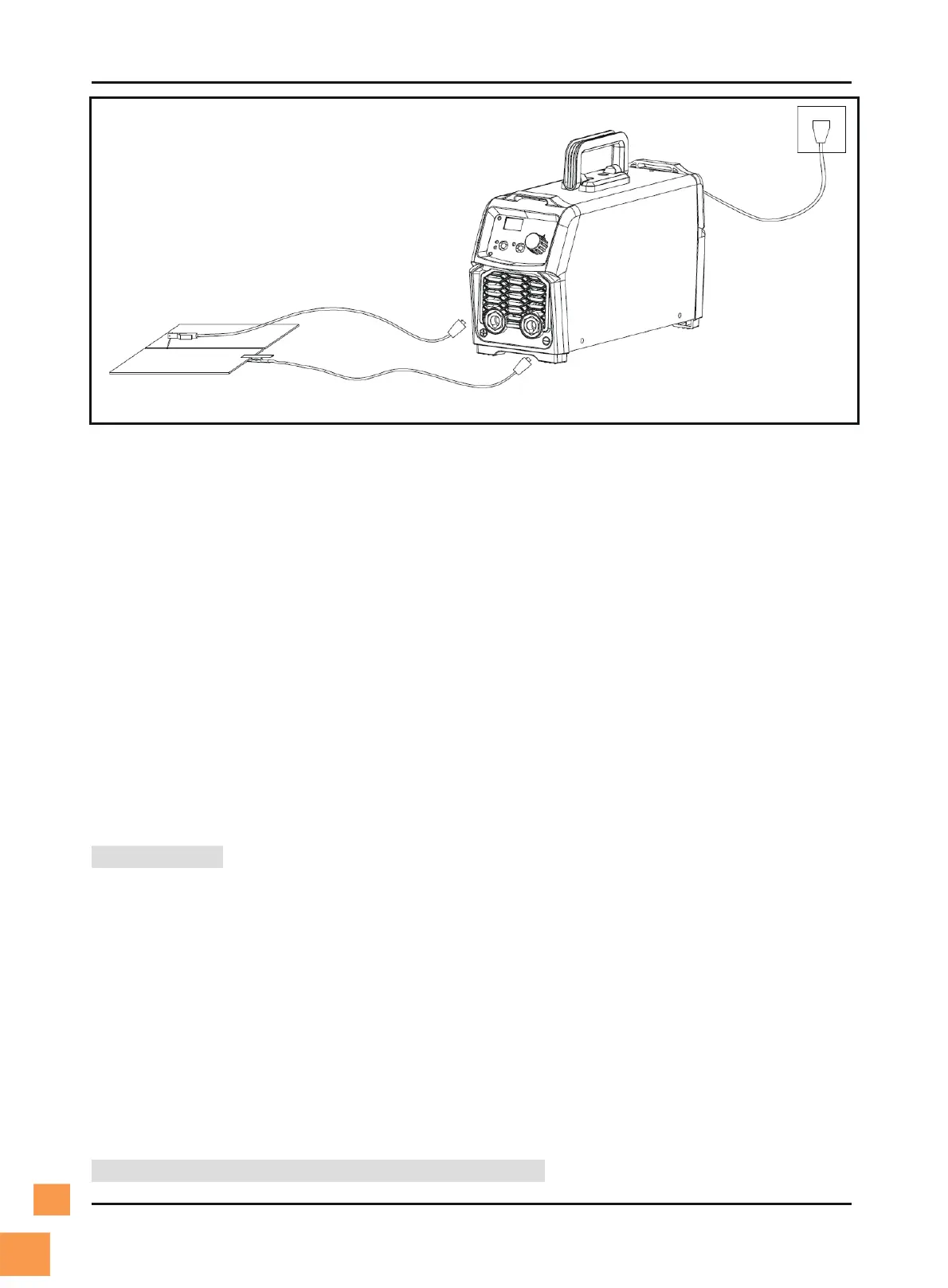

Fig.4 Schematic Diagram of MMA Welding

1) A primary power supply cable is available for this welding machine. Connect the power supply cable

to the rated input power.

2) The primary cable should be tightly connected to the correct socket to avoid oxidization.

3) Check whether the voltage value varies in acceptable range with a multi-meter.

4) Insert the cable plug with electrode holder into the “+” socket on the front panel of the welding

machine, and tighten it clockwise.

5) Insert the cable plug with work clamp int

o the “-” socket on the front panel of the welding machine,

and tighten it clockwise.

6) Ground connection is needed for safety purpose.

The connection as mentioned above in 4) and 5) is DCEP connection. Operator can choose DCEN

connection according to workpiece and electrode application requirement. Generally, DCEP connection

is recommended for basic electrode, while there is no special requirement for acid electrode.

11.3 Operation

1) After being installed according to the above method, and the power switch being switched on, the

machine is started with the power LED on and the fan working.

2) Pay attention to the polarity when connecting. Phenomena such as unstable arc, spatter, and

electrode sticking could happen if improper mode is selected. Exchange the polarity if necessary.

3) Select cable with larger cross-section to reduce the voltage drop if the secondary cables (welding

cable and earth cable) are long.

Preset the welding current according to t

he type and size of the electrode, clip the electrode and then

welding can be carried out by short circuit arc ignition. For welding parameters, please refer to the below

table.

11.4 Welding parameters table (for reference only)

Loading...

Loading...