11

/

18

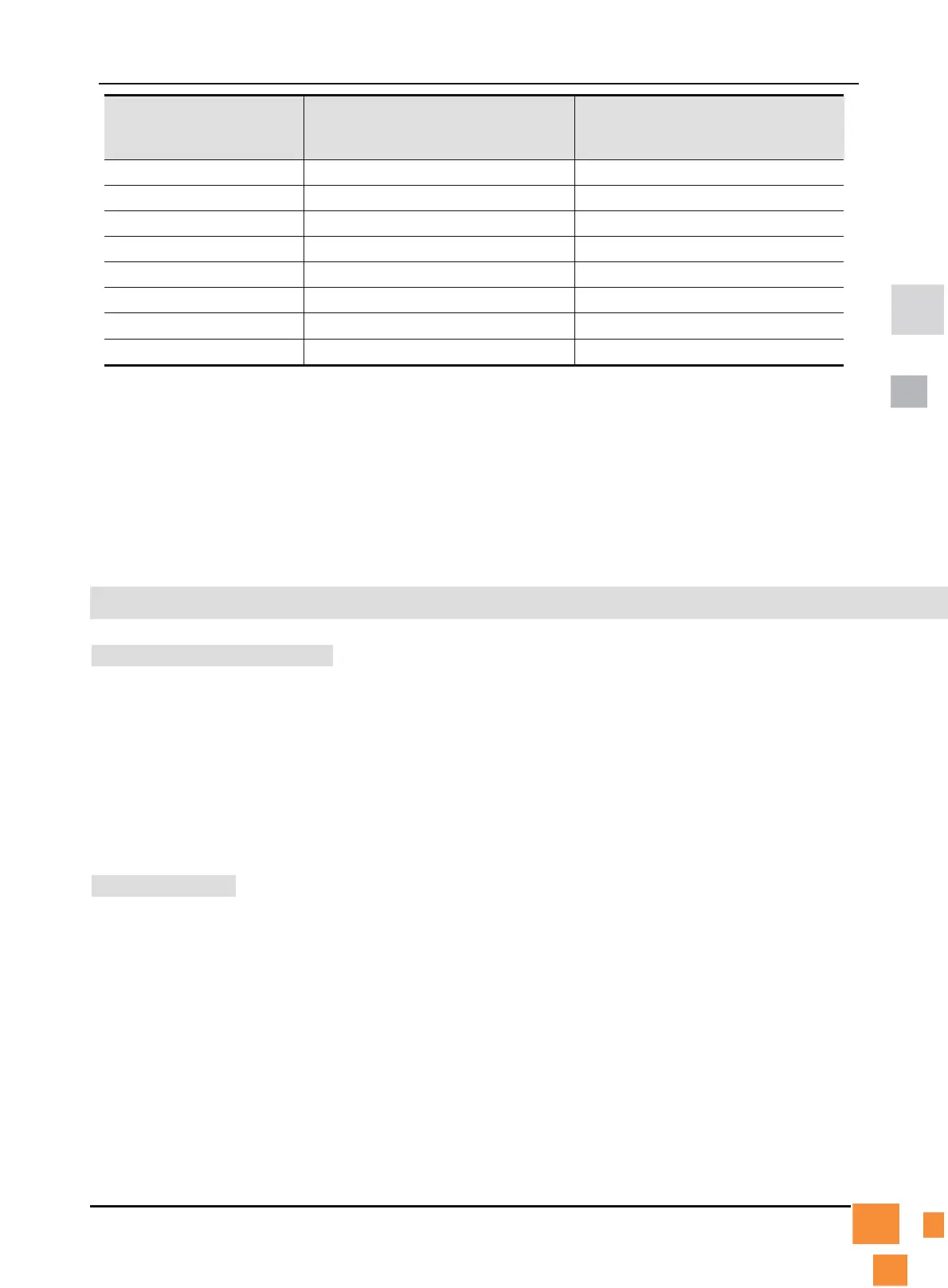

Electrode Diameter

(mm)

Recommended Welding Current

(A)

Recommended Welding

Voltage (V)

1.0 20~60 20.8~22.4

1.6 44~84 21.76~23.36

2.0 60~100 22.4~24.0

2.5 80~120 23.2~24.8

3.2 108~148 23.32~24.92

4.0 140~180 24.6~27.2

5.0 180~220 27.2~28.8

6.0 220~260 28.8~30.4

Note: This table is suitable for mild steel welding.

12. CAUTION

12.1 Working Environment

1) Welding should be carried out in dry environment with humidity of 90% or less.

2) The temperature of the working environment should be between -10℃and 40℃.

3) Avoid welding in the open air unless sheltered from sunlight and rain. Keep it dry at all times and do

not place it on wet ground or in puddles.

4) Avoid welding in dusty area or environment with corrosive chemical gas.

5) Gas shielded arc welding should be operated in environment without strong airflow.

12.2 Safety Tips

Over-current/over-heating protection circuit is installed in this machine. When the output current or inner

temperature exceeds the set standard, the machine will stop automatically. However, excessive use of

machine will lead to welder damage. Therefore, please note:

1) Ventilation

This welder can create powerful welding current that has strict cooling requirements that cannot be

met with natural ventilation. Therefore the internal fan is very important in enabling the machine to

work steadily with effective cooling. The operator should

make sure that the louvers be uncovered

and unblocked. The minimum distance between the machine and nearby objects should be 30cm.

Good ventilation is of critical importance to the normal performance and lifespan of the machine.

Loading...

Loading...