13

/

18

welding cable and labor protection supplies.

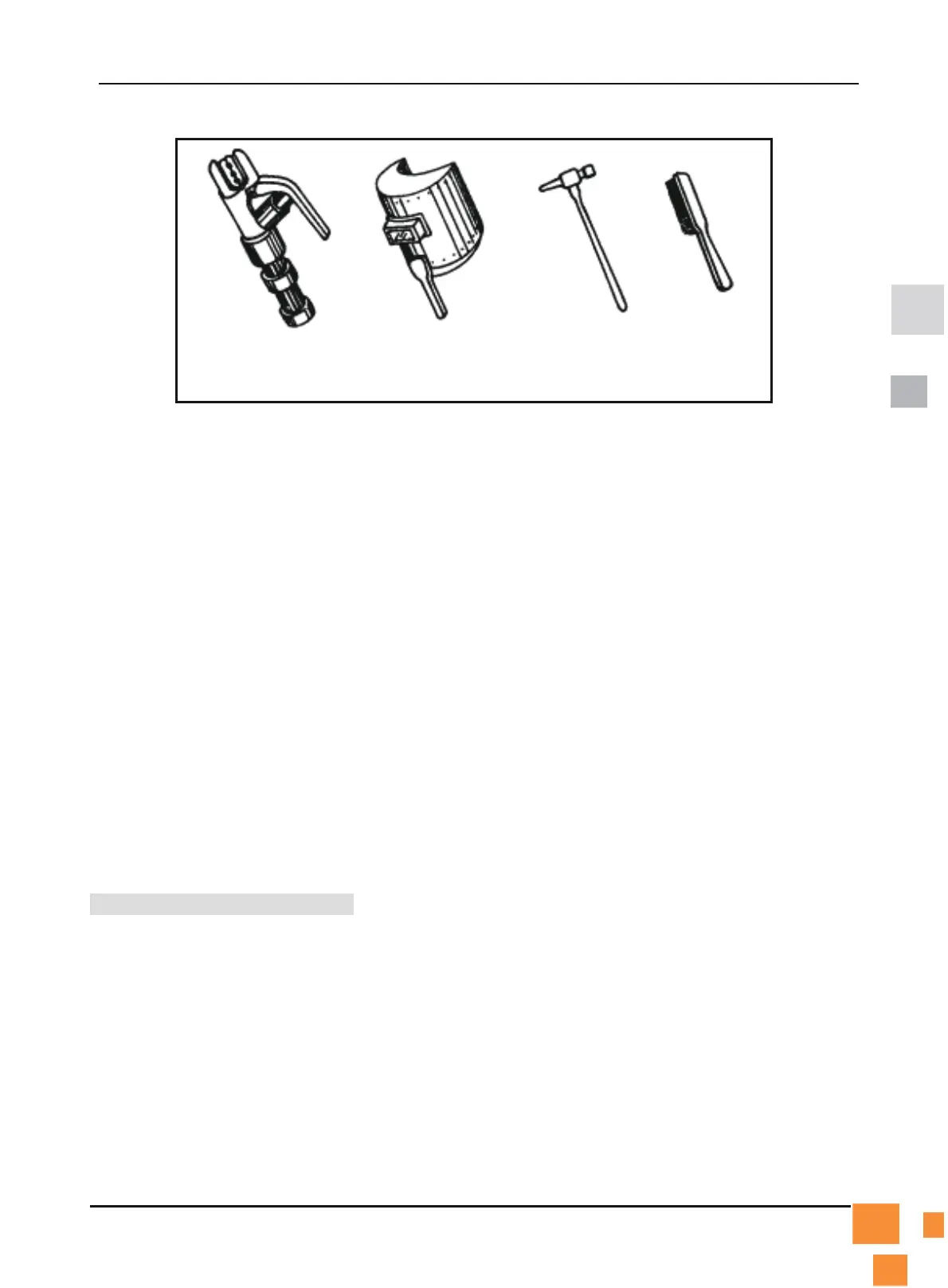

a) electrode holder b) welding mask c) slag hammer d) wire brush

Fig. 5 Tools for MMA

a) Electrode holder: a tool for clamping electrode and conducting current, mainly including 300A type

and 500A type.

b) Welding mask: a shielding tool for protecting eyes and face from injuring due to arc and spatter,

including handholding type and helmet type. Colored chemical glass is installed on the viewing window

of the mask to filter ultraviolet ray and infrared ray. Arc burning condition and weld crater condition can

be observed from the viewing window during welding. Thus, welding can be carried out by oper

ators

conveniently.

c) Slag hammer (peen hammer): for the use of removing slag crust on the surface of weld joint.

d) Wire brush: for the use of removing dirt and rust at the joints of the workpiece before welding, as well

as cleaning the surface of weld joint and the spatter after welding.

e) Welding cable: generally cables formed from many fine copper wires. Electrode holder and welding

machine are connected via a cable, and this cable is named as welding cable (live wire). Welding

machine and workpiece are connected via another

cable (earth wire). The electrode holder is covered

with insulating material performing insulation and heat insulating.

13.3 Basic Operation of MMA

1) Welding joint cleaning

Rust and greasy dirt at the joint should be removed completely before welding in order to implement arc

igniting and arc stabilizing conveniently as well as ensure the quality of weld joint. Wire brush can be

used for condition with low requirement on dust removal; grinding wheel can be used for condition with

high requirement on dust removal.

2) Posture in operating

Take flat welding of butt joint and T-shaped joint from left to right as an example. (See Fig. 6) The

operator should stand at the right s

ide of the working direction of weld joint with mask in the left hand and

electrode holder in the right hand. The left elbow of the operator should be put on his left knee to prevent

Loading...

Loading...