SH

16 © HOLMS INDUSTRI AB, ALL RIGHTS RESERVED 161230.

Operation

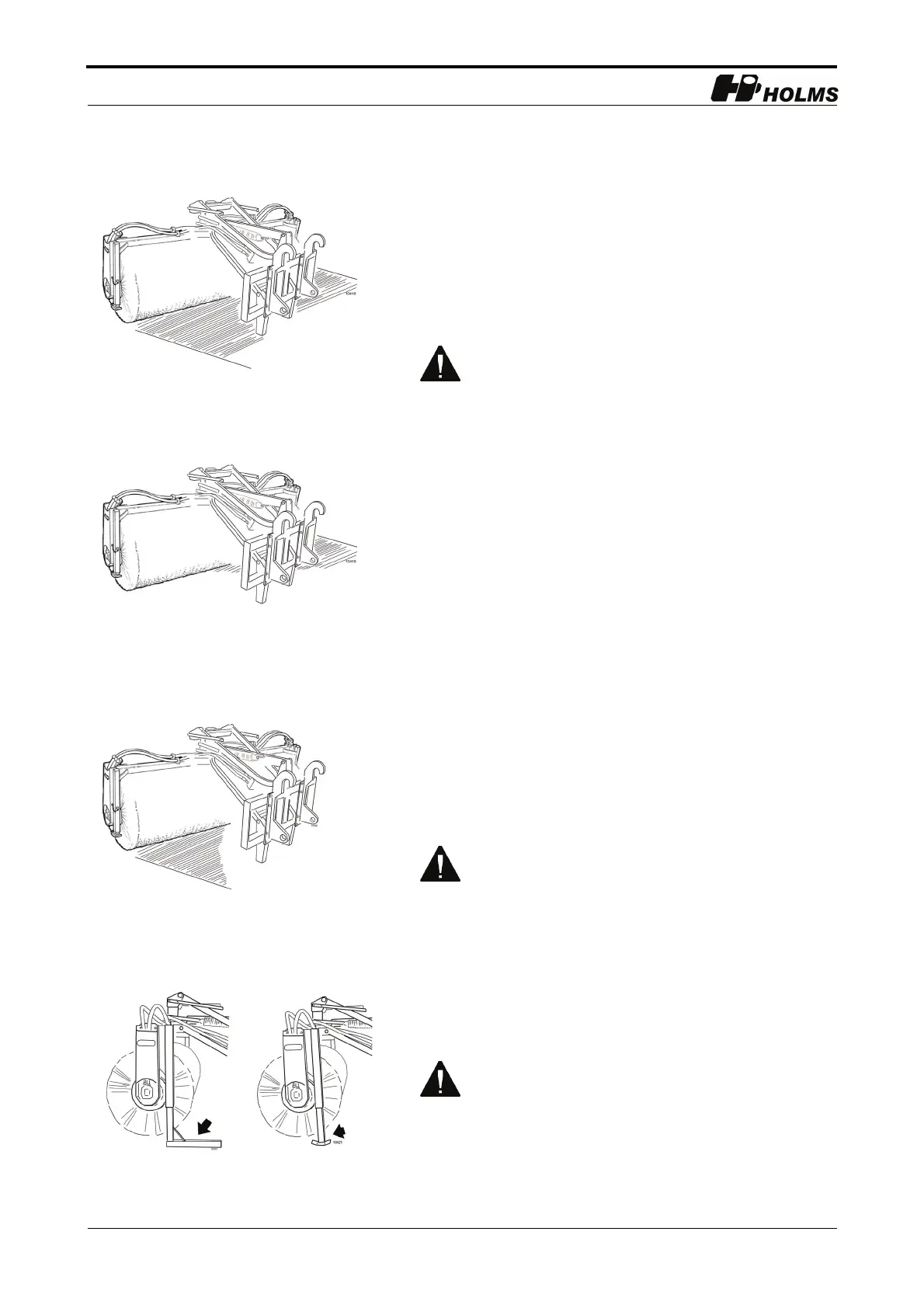

Settings for sweeping will normally be as per section

“Adjusting the height and tilt of the sweeper roller” on

page 14. The yellow markings on the height indicator and

tilt indicator must line up. In this position the loader

attachment is vertical to the ground. The sweeper roller

then applies even pressure along its entire width (see

figure 13).

If greater pressure is required on either side of the roller

or if the roller has become unevenly worn, this can be

adjusted by altering the tilt. Tilting the sweeper

backwards produces greater pressure on the side of the

sweeper roller angled towards the carrier (see figure 14).

Tilting the sweeper forwards produces greater pressure

on the side of the sweeper roller angled away from the

carrier (see figure 15).

When transporting the sweeper on the carrier the sweeper

shall be in uptilted position.

Disconnection from carrier when using standard

attachments

1. Release the machine attachment’s lock pins before

lowering the sweeper roller to the ground in order to

prevent damage to the counterbalancing system.

2. Lower and secure the supports in parking position.

3. Lower the sweeper roller to the ground.

4. Release the quick couplings for the third and fourth

function hydraulic outlet or the hydraulic motor

circuit and electrical cabling.

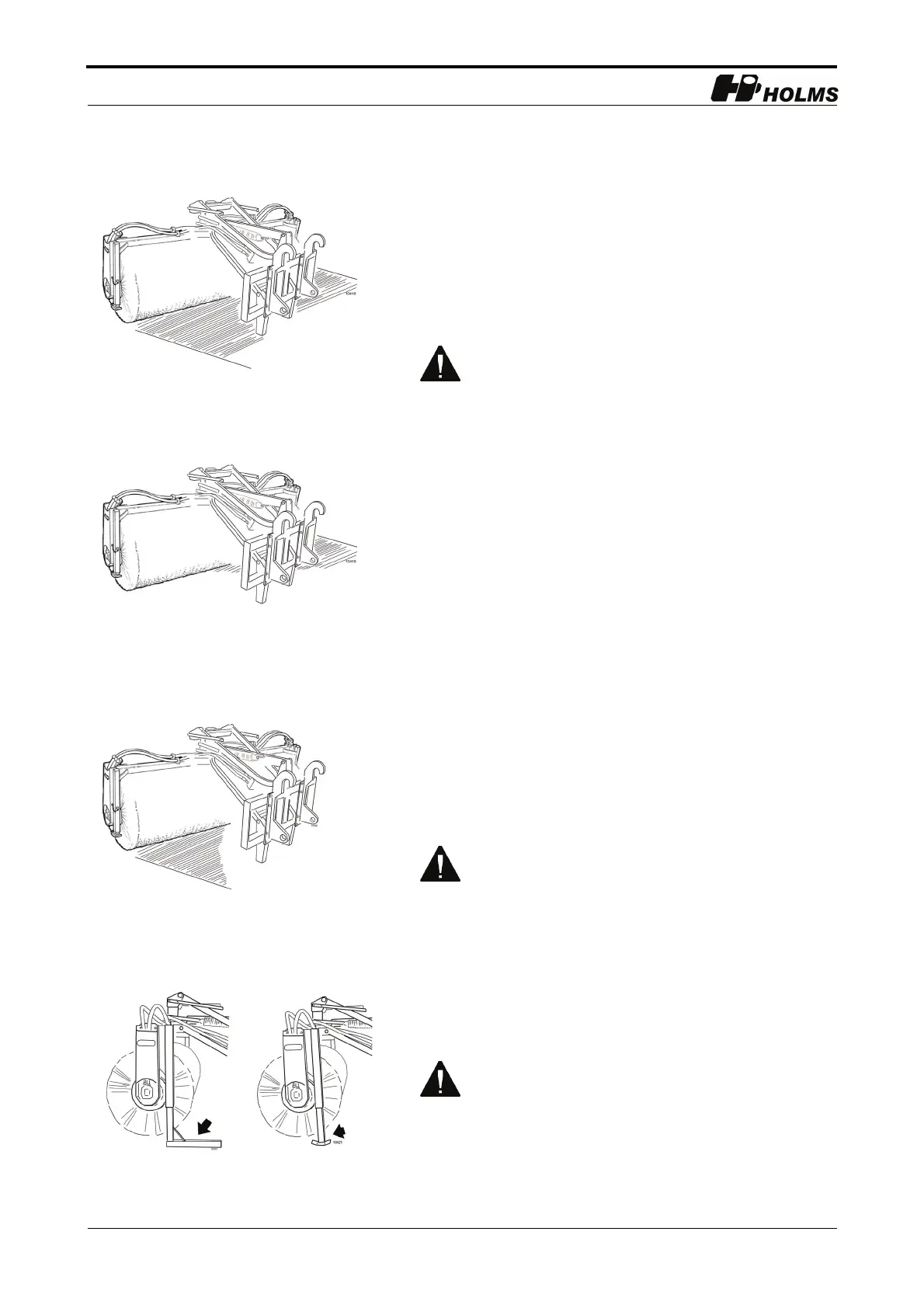

Disconnection from carrier without own lifting device

1. Position the supports in the parking position (see

figure 16). Set the connection device pin in the lifting

position.

Do not use the carrier’s lifting function to adjust

the ground pressure. Use the adjustment lever

instead (see figure 11 on page 15).

The brush will become deformed if the sweeper

roller is not parked on the supports.

Before disconnection the roller must be in line with

the angling cylinder and any lateral movement.

13.Sweeper roller with even pressure

14.Sweeper tilted backwards

15.Sweeper tilted forwards

16.Supports in parking position

Loading...

Loading...