HOMELITE

SAW CHAIN

Your saw has a

fast-cutting

chain with a sprocket which

matches it in

pitch.

When the

chain

is to be replaced,

always install

a

new sprocket of matching

pitch

because

a

worn sprocket would be out-of-pitch and damage lhe

new chain.

Not only

lor

fastest cutting, but

also

for maximum life

of

the chain and all saw

parts,

always keep the chain

in

such

good,

sharp condition that

bearing down hard to

make lhe chain cut ls unnecessary. When the sawdust

turns

from

chips into a line

powder

and

you

lind

your-

sell

pressing

hard

to

feed

the chain, STOP IMMEDI-

ATELY and lile the chain.

Uniformity

and accuracy are

necessary for

success in

liling saw

chain. These are easiest to obtain

with a file

holder

which has

the required 35o top

filing angles

marked

on it, and also holds the lile at correct height

(1/10

ol file diameter above

top

plate

of tooth) to

pro-

duce

the required side

plale

angle and culting

edge.

For new 3/8

pitch

chain,

a

7132 diameler

"fast-cut"

round

file

and

holder

(our

assembly A-23133-A) is re-

quired.

When about

half of the original

tooth steel has

been liled away,

you

should switch first to

a 13164"

diamefer file and

later on lo a 3116tt

diameter file. The

reason

for

using a smaller

diameter

lile is the

slight

taper

of

the

tooth's top

plate

which reduces

the tooth

size.

HOW TO

FTLE

CUTTERS

A chain

liling vise holds

the cutters rock-steady for

filing;

but

you

can do a satisfactory

job

"on

the

bar"

if

you

tighten up the tension a

bit

so

the chain

does

not

wobble,

and do all

of the

filing

near the midpoint of the

bar.

ALWAYS WEAR GLOVES OR

PROTECT YOUR

HANDS WITH A RAG

WHEN WORKING

ON

THE

CHAIN.

Be

sure

to

file all cutters

to lhe same length

-

if

you

re-

place

worn

cutters, lile the new ones back to the same

length

as the other teelh

in

the

loop

so that all cutters

get

a biting

chance.

Here's What

You Should Do:

1. Hold file against

cutter lace

at 35o angle

(marked

on

file holder).

2. Keep file level

-

do not let it dip or rock.

3.

File in one direDtion only-towards

lront

corner ol

the tooth. Move file away

from

tooth face on return

stroke.

4. Use

light

but lirm

pressure,

mostly

towards back ol

tooth. Avoid heavy downward filing

pressure.

The

hofder will keep 10o/o ol lhe tile above the lop

plate,

automatically

producing

a beveled hollow-ground

under edge.

5. Put a

few

lirm strokes

on

every

tooth,

filing all

cutters

on one side

of the chain, then

all cutters on the other.

Rotate file

in holder

occasionally.

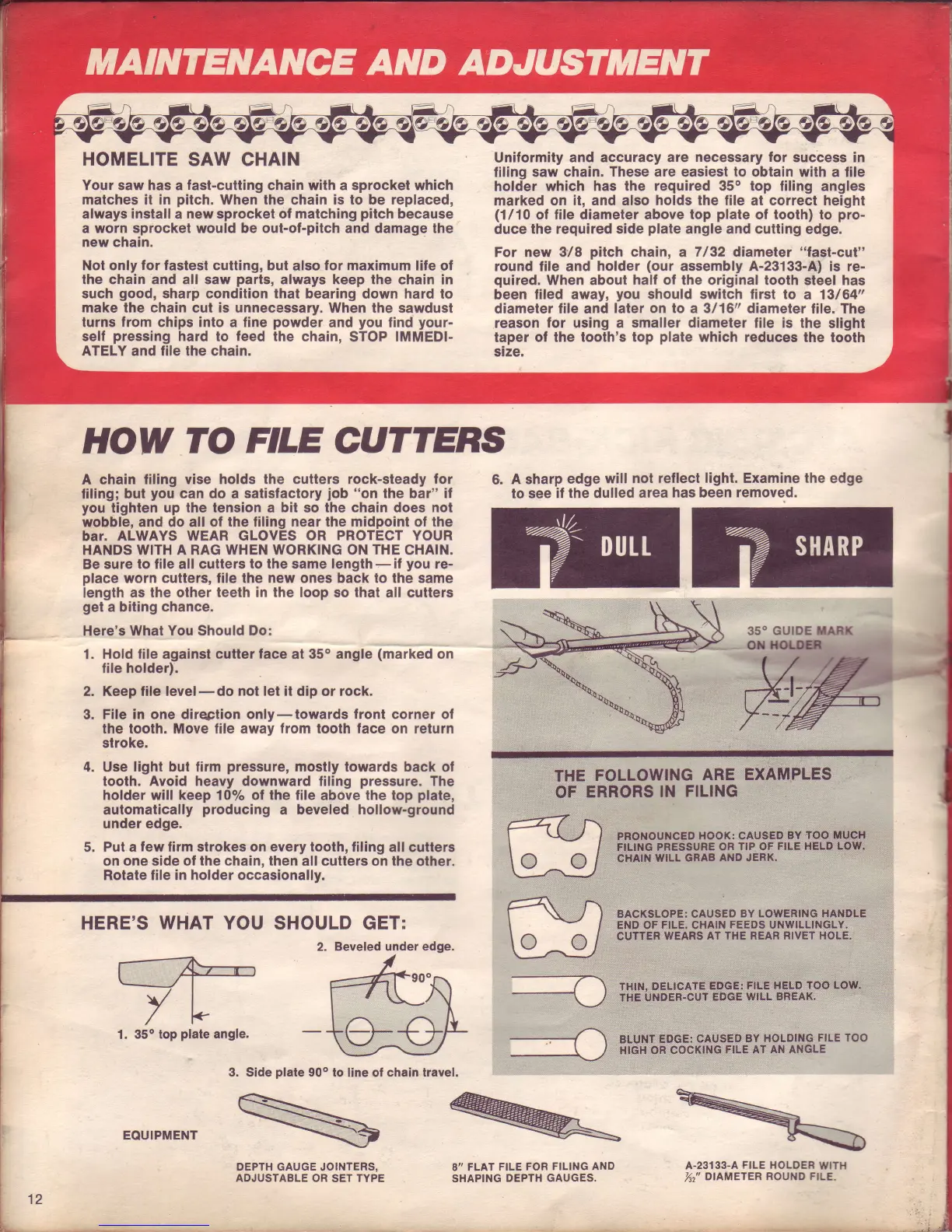

HERE'S

WHAT

YOUSHOULD GET:

2. Beveled

under edge.

3. Side

plale

90o

to line of

chain

travel.

6.

A sharp

edge

will

not reflect light. Examine the edge

to see

if the dulled

area

has been removed.

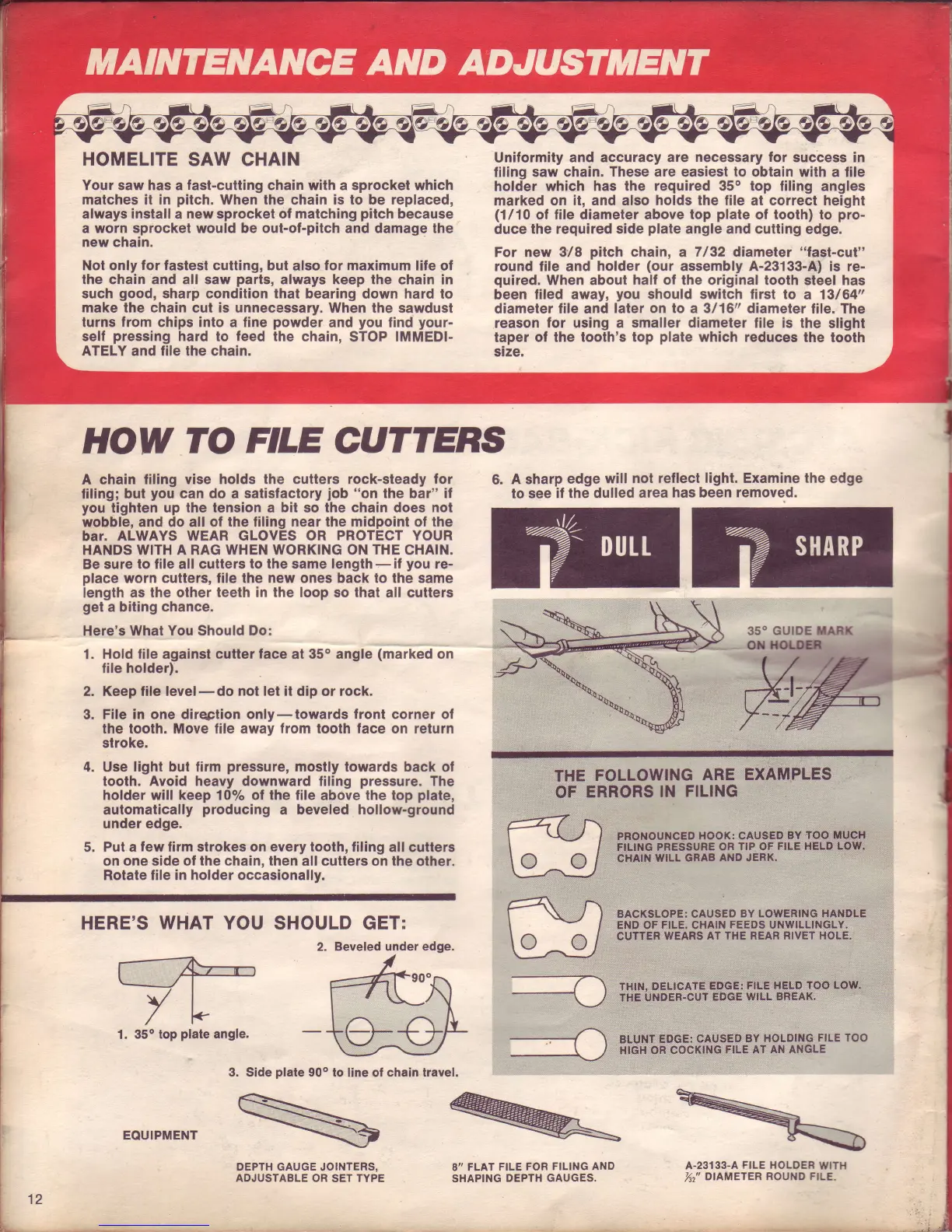

DEPTH GAUGE

JOINTERS,

ADJUSTABLE

OR SET

TYPE

A.23133.A

FILE HOLDER

WITH

I/3'"

DIAMETER

ROUND FILE.

I

w@

THE

FOLLOWING

ARE

EXAMPLES

OF ERRORS

IN

FILING

PRONOUNCED

HOOK: CAUSED

BY:IOO

IIUCH

FILIIIG PRESSUR€

OR

TIP

OF

FILE

HELD

LOW.

CHAIN

WILL GRAB

ANO JERX,

.'.

BACKSLOPE: CAUSED

BY LOWERING HANDLE

END OF

FILE.

CHAIN

FEEDS

UNWILLINGLY,

CUTTER

WEARS

AT THE REAR RIVET HOLE.

THIN,

DELICATE

EDGE:

FILE HELD

TOO LOW.

THE UNDER-CUT

EDGE WILL

BREAK.

BLUNT EDGE:

CAUSED

BY HOLDIIG

FILE

TOO

HIGH

OR COCKING

FILE AT AN ANGLE

<,

tr-,.--gJ

n_l

P^9/

-----\_/

---{l

_-.---__\--l

8,

FLAT FILE

FOR FILING

AND

SHAPING

DEPTH GAUGES,

plate

angle.

EOUIPMENT

Loading...

Loading...