FUELTANK

and

FILTER

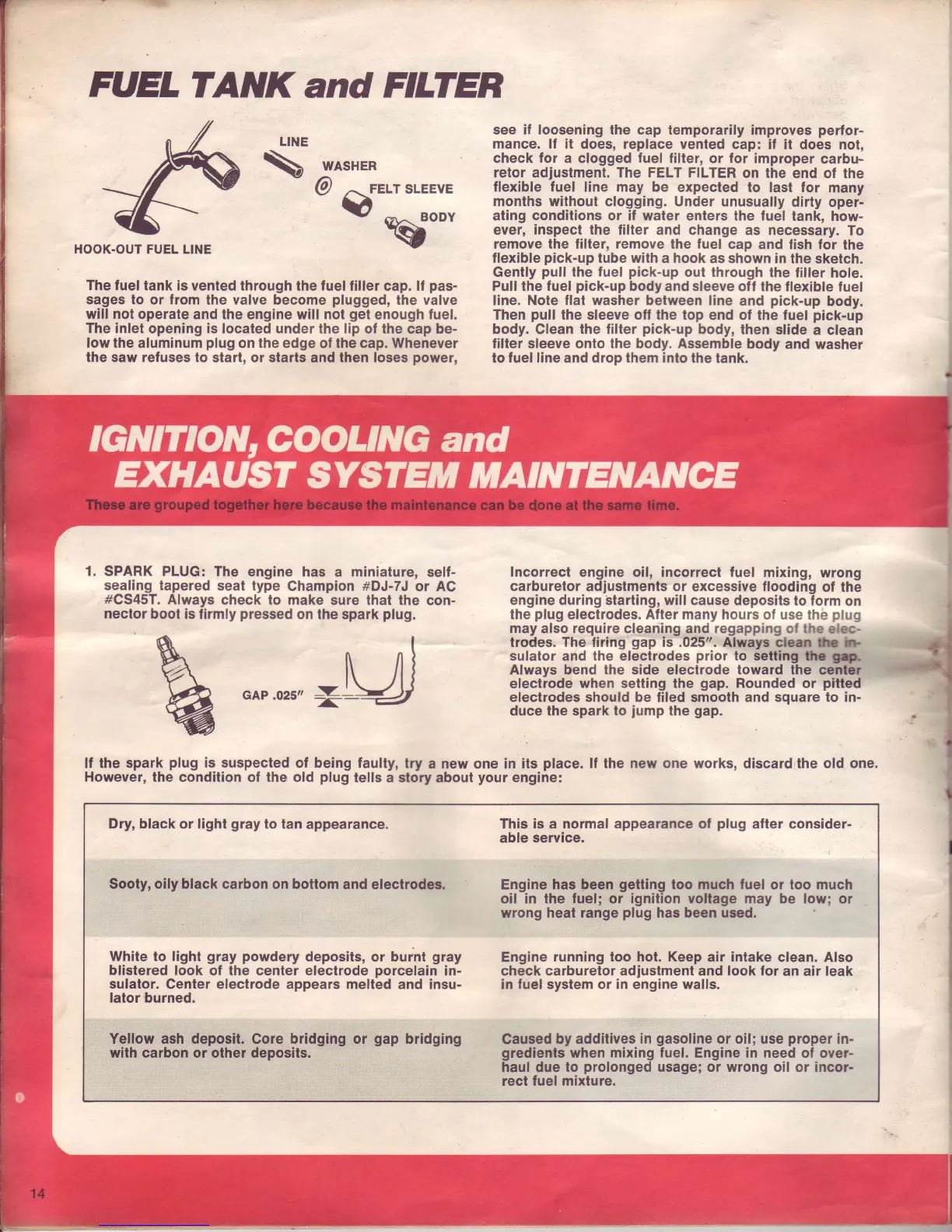

LINE

\

r,r/AsHER

(9)

--FELT

SLEEvE

V

-^

"oo,

q--

see if loosening the cap temporarily

improves

perfor-

mance. lf it

does, replace vented cap:

if it does not,

check

for

a clogged tuel filter,

or

for

improper

carbu-

retor

adjustment. The

FELT

FILTER

on the

end ol the

llexible fuel line may

be expected to last for

many

monlhs

withoul clogging. Under unusually

dirty oper-

ating

conditions

or if water enters the fuel

tank,

how-

ever,

inspecl the

filter and change

as

necessary.

To

remove the filler,

remove

the

fuel

cap

and fish for

the

llexible

pick-up

tube with a hook

as shown in

the sketch.

Gently

pull

the

fuel

pick-up

out through

the filler

hole.

Pull the fuel

pick-up

body and sleeve olf the

flexible fuel

line. Note

flat

washer between line

and

pick-up

body.

Then

pull

the sleeve off the top

end of the fuel

pick-up

body. Clean the filter

pick-up

body,

then slide

a clean

filter

sleeve onto the body. Assemble

body and

washer

to

fuel

line and drop them into the tank.

HOOK-OUT

FUEL LINE

The fuel

tank is vented

through the

fuel

filler cap. lf

pas-

sages to or from

the

valve

become

plugged,

the valve

will not operate

and the engine will not

get

enough

fuel.

The inlet opening is located under

the

lip

of the cap be-

low the

aluminum

plug

on the edge

of

the cap.

Whenever

the saw refuses to

start, or starts and then loses

power,

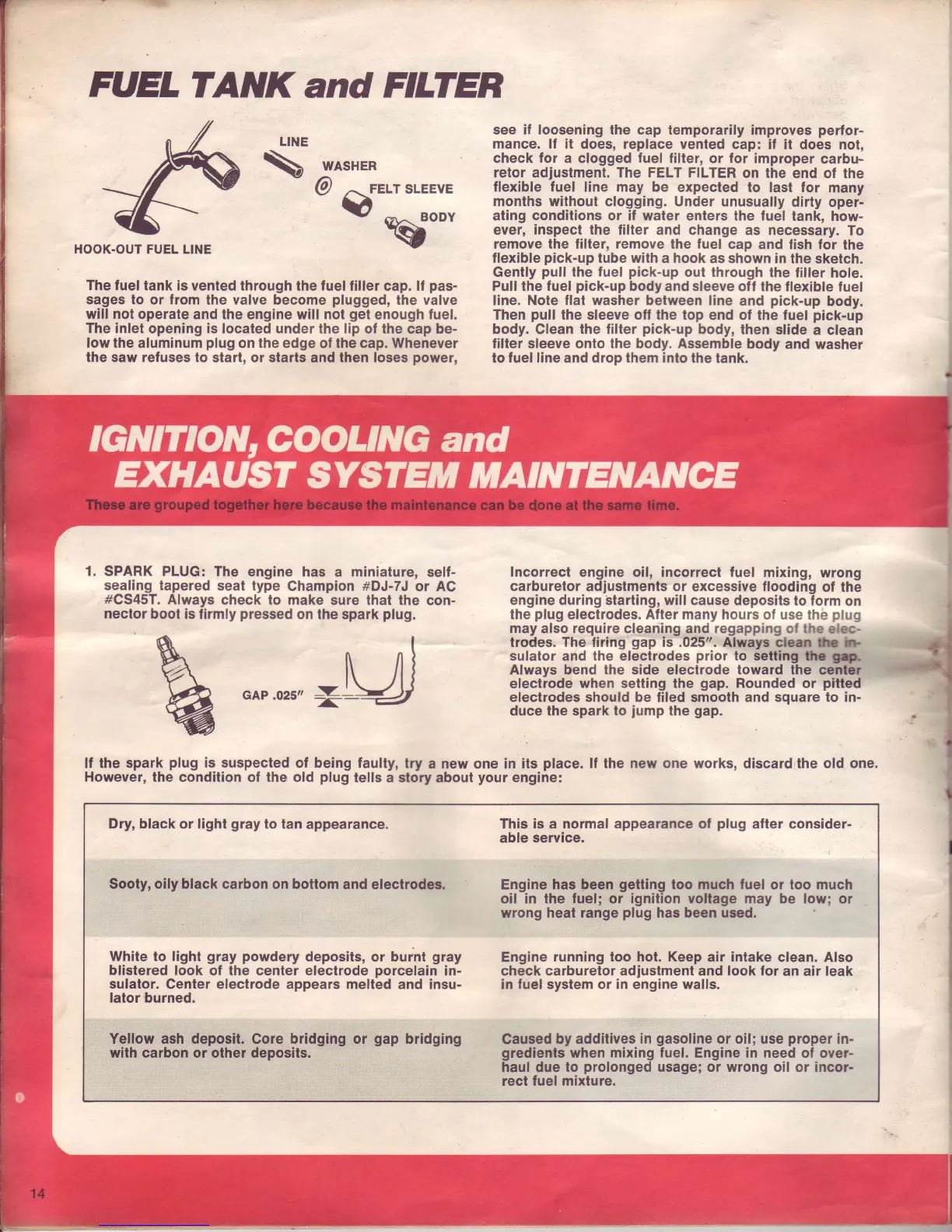

1. SPARK PLUG:

The engine

has a miniature,

self-

seafing tapered

seat type

Champion

#DJ-7J

or AC

#CS45T.

Always

check to make

sure that the con-

nector boot

is firmly

pressed

on

lhe spark

plug.

Incorrect engine

oil, incorrect fuel mixing,

wrong

carburetor

adjustments or excessive llooding

of the

engine during Starting, will cause

deposits to form

on

the

pluq

electrodes. After manv hours of use thb

pluq

.AP.O2'"=v,l

the

plug

electrodes. After many hours of use thb

plug

may

also

require cleaning and regapping ol

the

elec-

trodes. The liring

gap

is .025", Always

clc

b b

sulator and the electrodes

prior

to

settlng

it-lf$l

Always bend

the

side electrode

toward

the csl$

electrode

when setting the

gap.

Rounded or

pitted

electrodes should be filed smooth and square to in-

duce the spark lo

jump

the

gap.

t

lf the spark

plug

is suspected of

being

faulty,

lry

a new one

in its

place.

lf

the

new one works,

discard the

old one.

However, the condition

of the old

plug

tells a story about

your

engine:

Dry,

black or light

gray

to tan

appearance.

8ooly, oilyblack carbon on botlom

and electrode&

While to

light

gray powdery

deposits,

or burnt

gray

blistered look ol the center electrode

porcelain

in-

sulator.

Center electrode appears melted and insu-

lator burned.

Yellow

ash deposit. Core

bridging or

gap

bridging

with carbon or olher deposits.

This is

a

normal appearance of

plug

after consider-

able service.

Engine

has

peen

getting

too mueh fuel

or

too much

oil

in the fuel; or ignition voltage may be low;

or

wrong

heat range

plug

has been used.

Engine running too

hol. Keep

air intake clean.

Also

check carburetor

adjustment

and

look lor

an

air

leak

in

luel system or in engine walls.

Caused by

additives in

gasoline

or oil; use

proper

in-

gredients

when mixing

fuel.

Engine in need of over-

haul due to

prolonged

usage;

or

wrong

oil or incor-

rect fuel mixture.

Loading...

Loading...