SECTION 6-MAINTENANCE

8

ADJUSTMENT

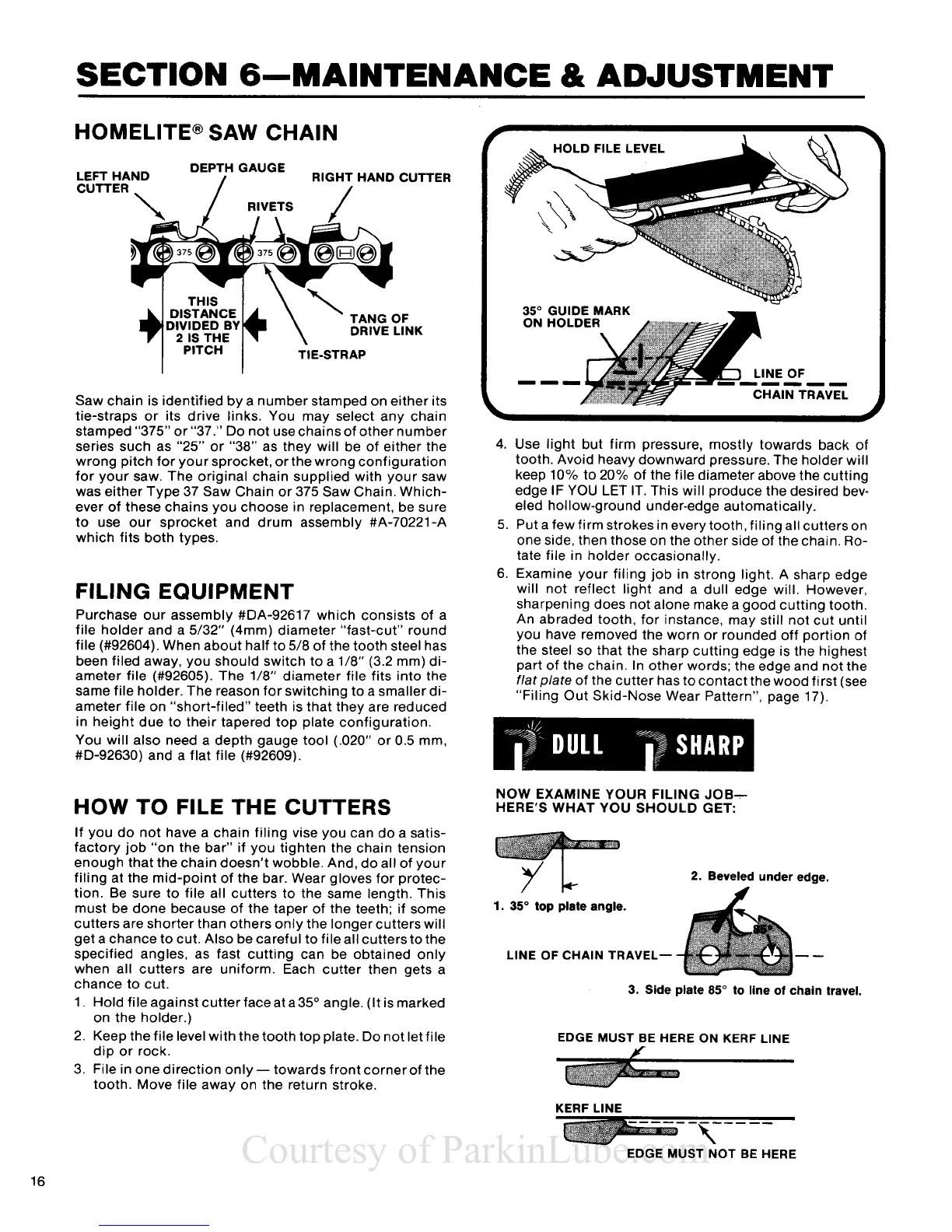

HOMELITEB SAW CHAIN

LEFT HAND

DEPTH GAUGE

/

RIGHT HAND CUTTER

CUTTER

-

/

\.

/

RIVETS

/

TIE-STRAP

Saw chain is identified by a number stamped on either its

tie-straps or its drive links. You may select any chain

stamped "375" or

"37." Do not usechainsof other number

series such as "25" or "38" as they will be of either the

wrong pitch for your sprocket, or the wrong configuration

for your saw. The original chain supplied with your saw

was either Type 37 Saw Chain or 375 Saw Chain. Which-

ever of these chains you choose in replacement, be sure

to use our sprocket and drum assembly #A-70221-A

which fits both types.

FILING EQUIPMENT

Purchase our assembly #DA-92617 which consists of a

file holder and a 5/32"

(4mm) diameter "fast-cut" round

file

(#92604). When about half to 5/8 of the tooth steel has

been filed away, you should switch to a

1/8" (3.2 mm) di-

ameter file

(#92605). The 1/8" diameter file fits into the

same file holder. The reason for switching to a smaller di-

ameter file on "short-filed" teeth is that they are reduced

in height due to their tapered top plate configuration.

You will also need a depth gauge tool

(.020" or 0.5 mm,

#D-92630) and a flat file

(#92609).

HOW TO FILE THE CUTTERS

If you do not have a chain filing vise you can do a satis-

factory job "on the bar" if you tighten the chain tension

enough that the chain doesn't wobble. And, do all of your

filing at the mid-point of the bar. Wear gloves for protec-

tion. Be sure to file all cutters to the same length. This

must be done because of the taper of the teeth; if some

cutters are shorter than others only the longer cutters will

get a chance to cut. Also be careful to file all cutters to the

specified angles, as fast cutting can be obtained only

when all cutters are uniform. Each cutter then gets a

chance to cut.

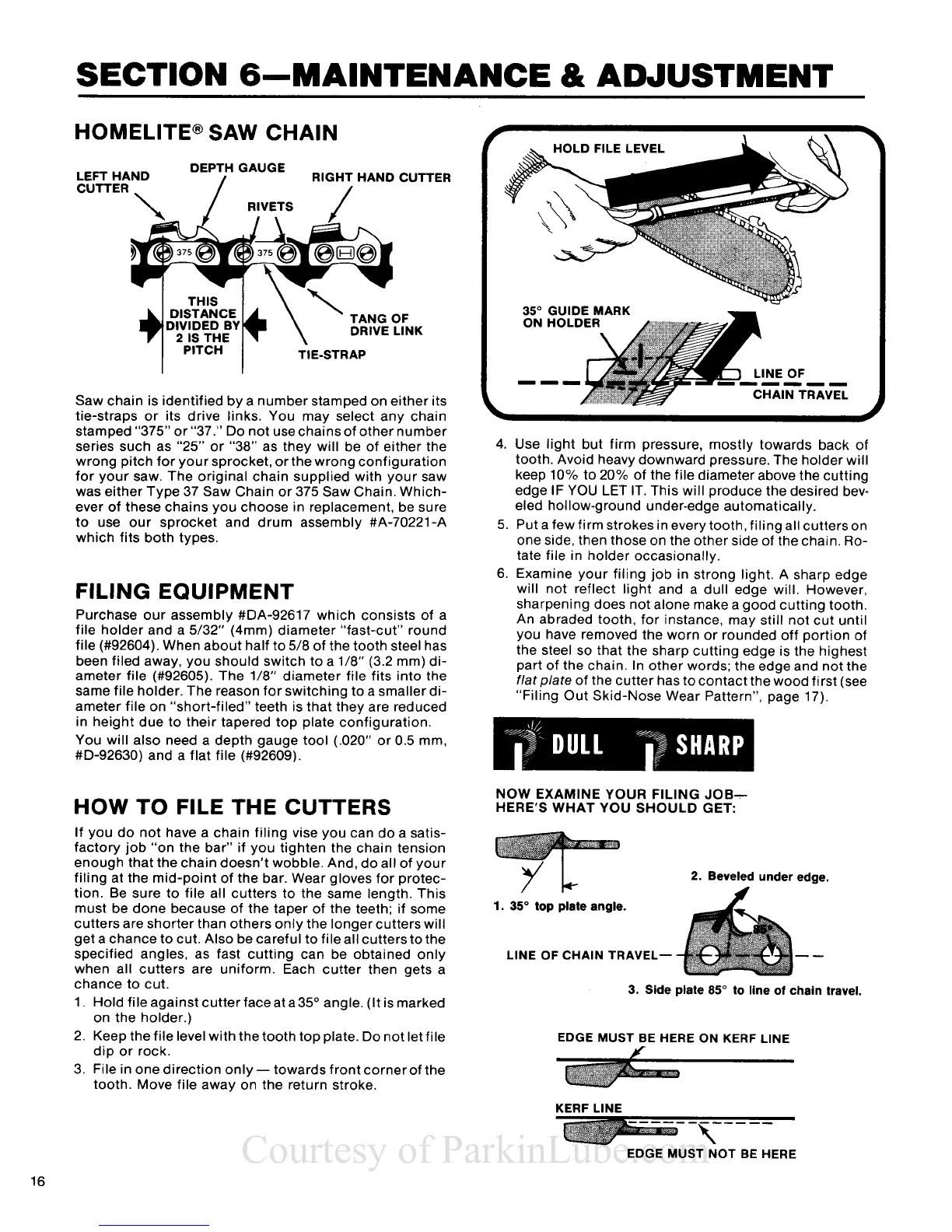

1. Hold file against cutter face at

a35O angle. (It is marked

on the holder.)

2. Keep the file level with the tooth top plate. Do not let file

dip or rock.

3. File in one direction only

-

towards front cornerof the

tooth. Move file away on the return stroke.

35" GUIDE MARK

ON HOLDER

CHAIN TRAVEL

4.

Use light but firm pressure, mostly towards back of

tooth. Avoid heavy downward pressure. The holder will

keep

10O/0 to 20% of the file diameter above the cutting

edge IF YOU LET IT. This will produce the desired bev-

eled hollow-ground under-edge automatically.

5.

Put a few firm strokes in every tooth, filing all cutterson

one side, then those on the other side of the chain. Ro-

tate file in holder occasionally.

6. Examine your filing job in strong light. A sharp edge

will not reflect light and a dull edge will. However,

sharpening does not alone make a good cutting tooth.

An abraded tooth, for instance, may still not cut until

you have removed the worn or rounded off portion of

the steel so that the sharp cutting edge is the highest

part of the chain. In other words; the edge and not the

flat

plate

of the cutter has to contact the wood first (see

"Filing Out Skid-Nose Wear Pattern", page 17).

NOW EXAMINE YOUR FILING JOB-

HERE'S WHAT YOU SHOULD GET:

2.

Beveled under edge.

I

1.

35" top plate angle.

LINE OF CHAIN TRAVEL-

--

3. Side plate 85" to line of chain travel.

EDGE MUST BE HERE ON KERF LlNE

1(

KERF LlNE

EDGE MUST NOT BE HERE

Loading...

Loading...