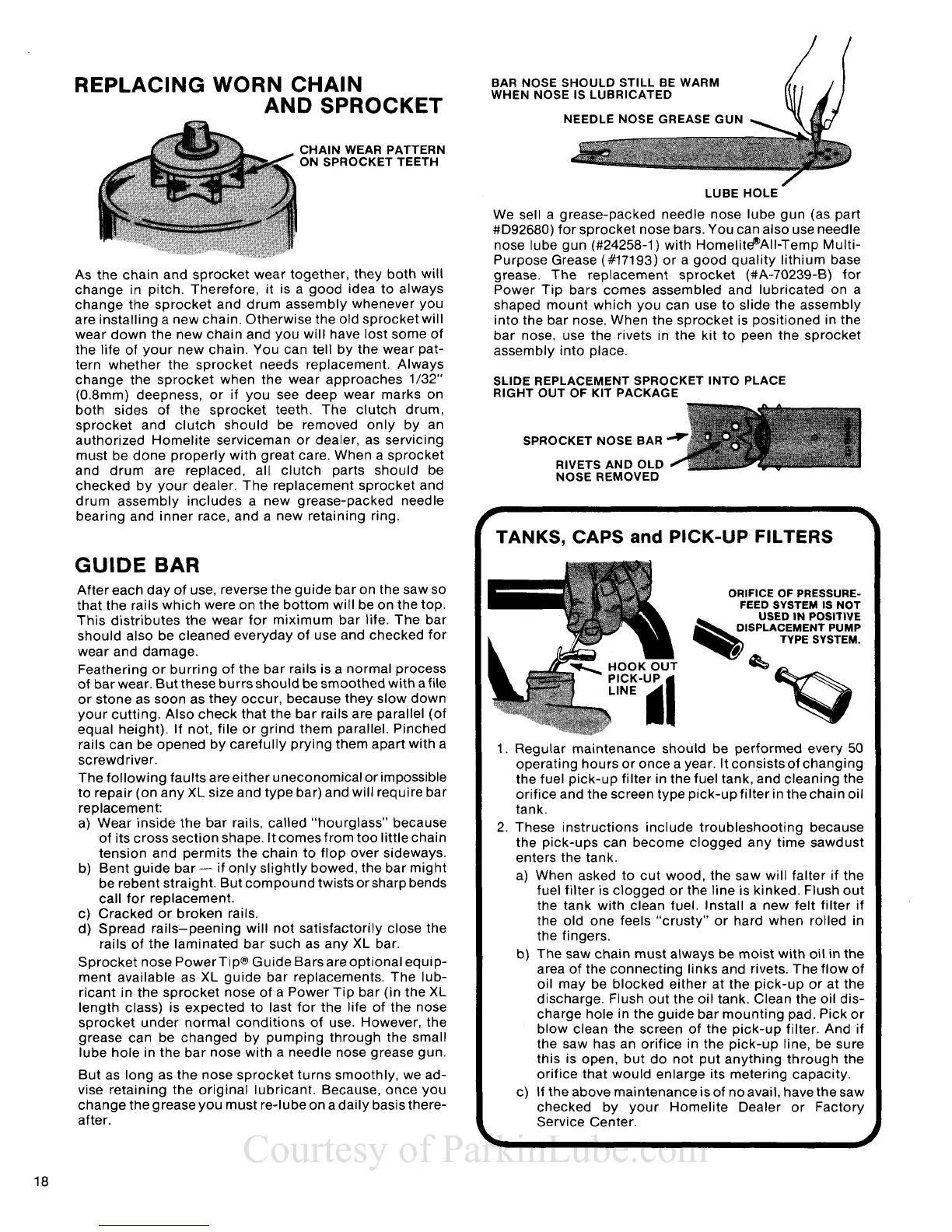

REPLACING WORN CHAIN

AND SPROCKET

As the chain and sprocket wear together, they both will

change in pitch. Therefore, it is a good idea to always

change the sprocket and drum assembly whenever you

are installing a new chain. Otherwise the old sprocket will

wear down the new chain and you will have lost some of

the life of your new chain. You can tell by the wear pat-

tern whether the sprocket needs replacement. Always

change the sprocket when the wear approaches 1/32"

(0.8mm) deepness, or if you see deep wear marks on

both sides of the sprocket teeth. The clutch drum,

sprocket and clutch should be removed only by an

authorized Homelite serviceman or dealer, as servicing

must be done properly with great care. When a sprocket

and drum are replaced, all clutch parts should be

checked by your dealer. The replacement sprocket and

drum assembly includes a new grease-packed needle

bearing and inner race, and a new retaining ring.

GUIDE BAR

After each day of use, reverse the guide bar on the saw so

that the rails which were on the bottom will be on the top.

This distributes the wear for

miximum bar life. The bar

should also be cleaned everyday of use and checked for

wear and damage.

Feathering or burring of the bar rails is a normal process

of bar wear. But these burrs should be smoothed with a file

or stone as soon as they occur, because they slow down

your cutting. Also check that the bar rails are parallel (of

equal height). If not, file or grind them parallel. Pinched

rails can be opened by carefully prying them apart with a

screwdriver.

The following faults are either uneconomical or impossible

to repair (on any XL size and type bar) and will require bar

replacement:

a) Wear inside the bar rails, called "hourglass" because

of its cross section shape. It comes from too little chain

tension and permits the chain to flop over sideways.

b) Bent guide bar

-

if only slightly bowed, the bar might

be

rebent straight. But compound twistsorsharp bends

call for replacement.

c) Cracked or broken rails.

d) Spread rails-peening will not satisfactorily close the

rails of the laminated bar such as any XL bar.

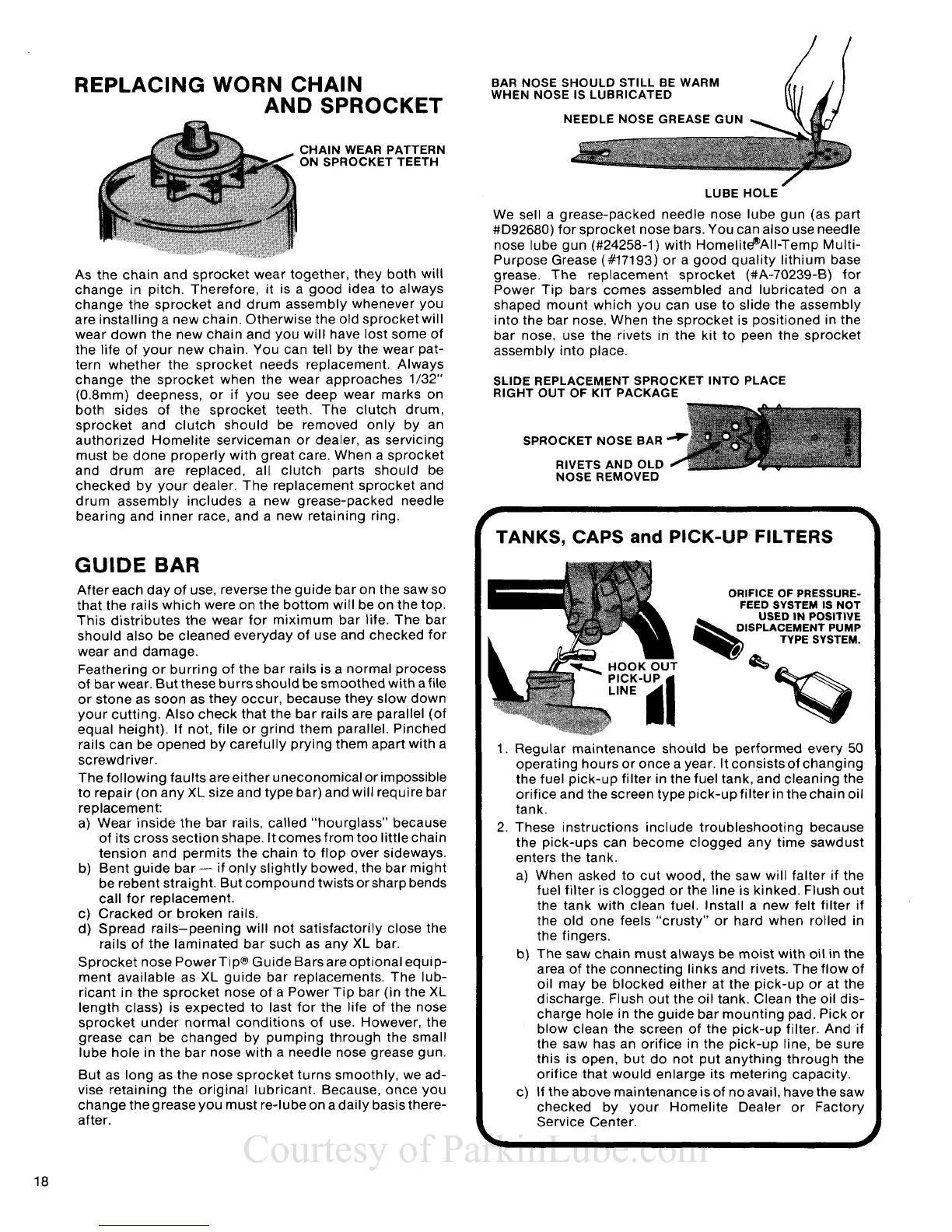

Sprocket nose

PowerTipm Guide Barsareoptional equip-

ment available as XL guide bar replacements. The lub-

ricant in the sprocket nose of a Power Tip bar (in the XL

length class) is expected to last for the life of the nose

sprocket under normal conditions of use. However, the

grease can be changed by pumping through the small

lube hole in the bar nose with a needle nose grease gun.

But as long as the nose sprocket turns smoothly, we ad-

vise retaining the original lubricant. Because, once you

change thegrease you must re-lube on a daily basis there-

after.

BAR NOSE SHOULD STILL BE WARM

WHEN NOSE IS LUBRICATED

NEEDLE NOSE GREASE GUN

LUBE HOLE

We sell a grease-packed needle nose lube gun (as part

#D92680) for sprocket nose bars. You can also use needle

nose lube gun

(#24258-1) with Homelit8All-Temp Multi-

Purpose Grease (W7193) or a good quality lithium base

grease. The replacement sprocket (#A-70239-8) for

Power Tip bars comes assembled and lubricated on a

shaped mount which you can use to slide the assembly

into the bar nose. When the sprocket is positioned in the

bar nose, use the rivets in the kit to peen the sprocket

assembly into place.

SLIDE REPLACEMENT SPROCKET INTO PLACE

RIGHT OUT OF KIT PACKAGE

SPROCKET NOSE BAR

RIVETS AND OLD

NOSE REMOVED

TANKS, CAPS

and

PICK-UP FILTERS

ORIFICE OF PRESSURE-

FEED SYSTEM IS NOT

USED

IN

POSITIVE

DISPLACEMENT PUMP

$6

TYPE SYSTEM.

1.

Regular maintenance should be performed every 50

operating hours or once a year. It consistsof changing

the fuel pick-up filter in the fuel tank, and cleaning the

orifice and the screen type

pick-up filter

in thechain oil

tank.

2. These instructions include troubleshooting because

the pick-ups can become clogged any time sawdust

enters the tank.

a) When asked to cut wood, the saw will falter if the

fuel filter is clogged or the line is kinked. Flush out

the tank with clean fuel. Install a new felt filter if

the old one feels "crusty" or hard when rolled in

the fingers.

b) The saw chain must always be moist with oil in the

area of the connecting links and rivets. The flow of

oil may be blocked either at the pick-up or at the

discharge. Flush out the oil tank. Clean the oil dis-

charge hole in the guide bar mounting pad. Pick or

blow clean the screen of the pick-up filter. And if

the saw has an orifice in the pick-up line, be sure

this is open, but do not put anything through the

orifice that would enlarge its metering capacity.

c) If the above maintenance is of no avail, have the saw

checked by your Homelite Dealer or Factory

Service Center.

Loading...

Loading...