11

EN2R--9023 9705R0--NE

CALCULATIONS

General

The maximum allowable leak--rate (according the EN676 and

EN746--2) is 0,1 % of the maximum burner capacity. The test

time necessary to detect a falling valve is a function of:

− inlet pressure

− test volume

− burner capacity.

When the volume between two safety--valves is bigger it

takes more time (in case of a leaking valve) to change the

status of the gas pressure switch. The correct OS--number

for the A4021A can be selected after calculating the

appropriate test--times for the intended application.

The switching point of the pressure--switch is set to 50 % of

the maximum inlet pressure.

ThetestperiodTpiscalculatedfromtheinletpressurePi,the

test volume Vp ( see Table 4.) and maximum burner capacity

Qm, in formula:

Tp ≡

2xPixVp

Qm

[s]

Pi = inlet pressure [mbar]

Vp = test volume [ dm

3

],seealsoTable4.

Qm = burner capacity [dm

3

/h]

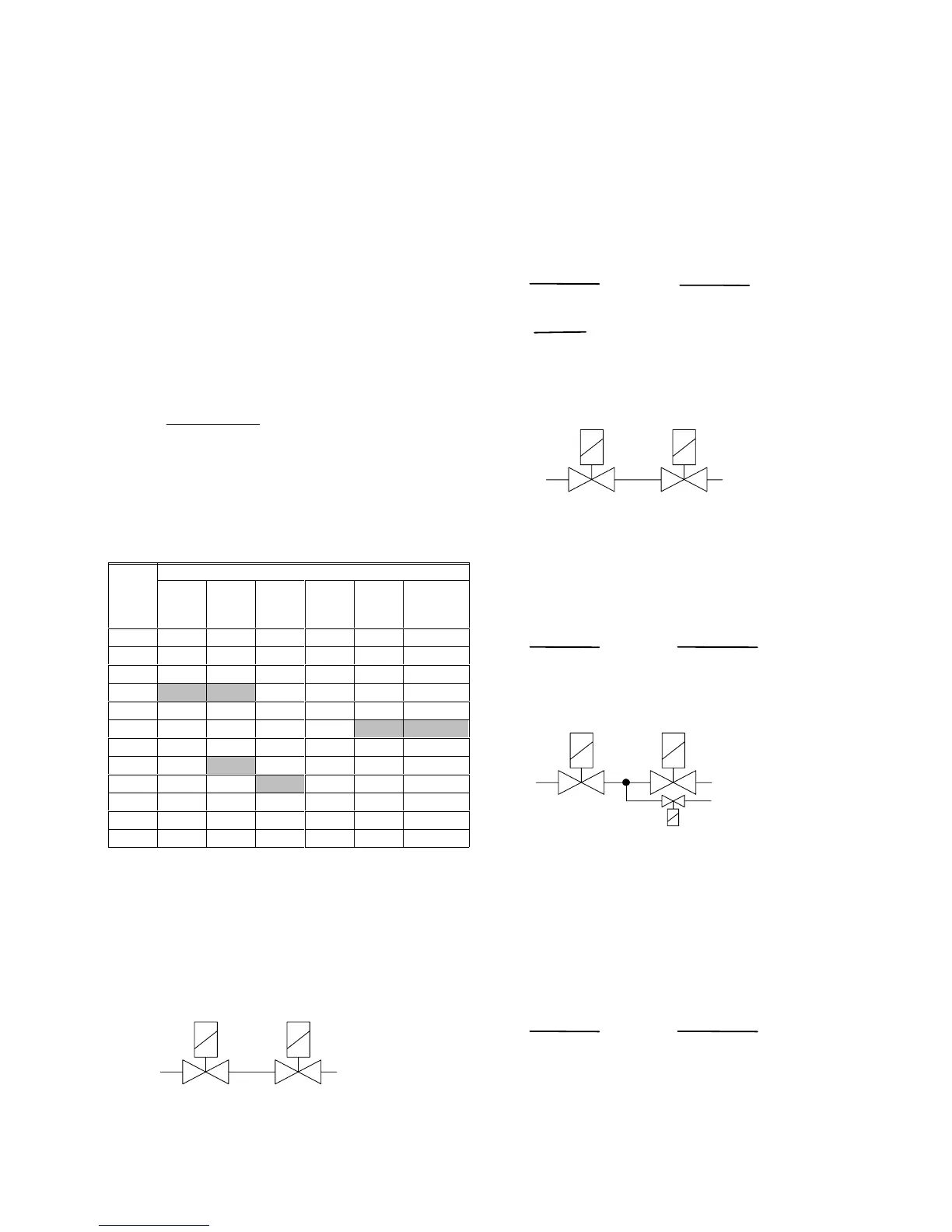

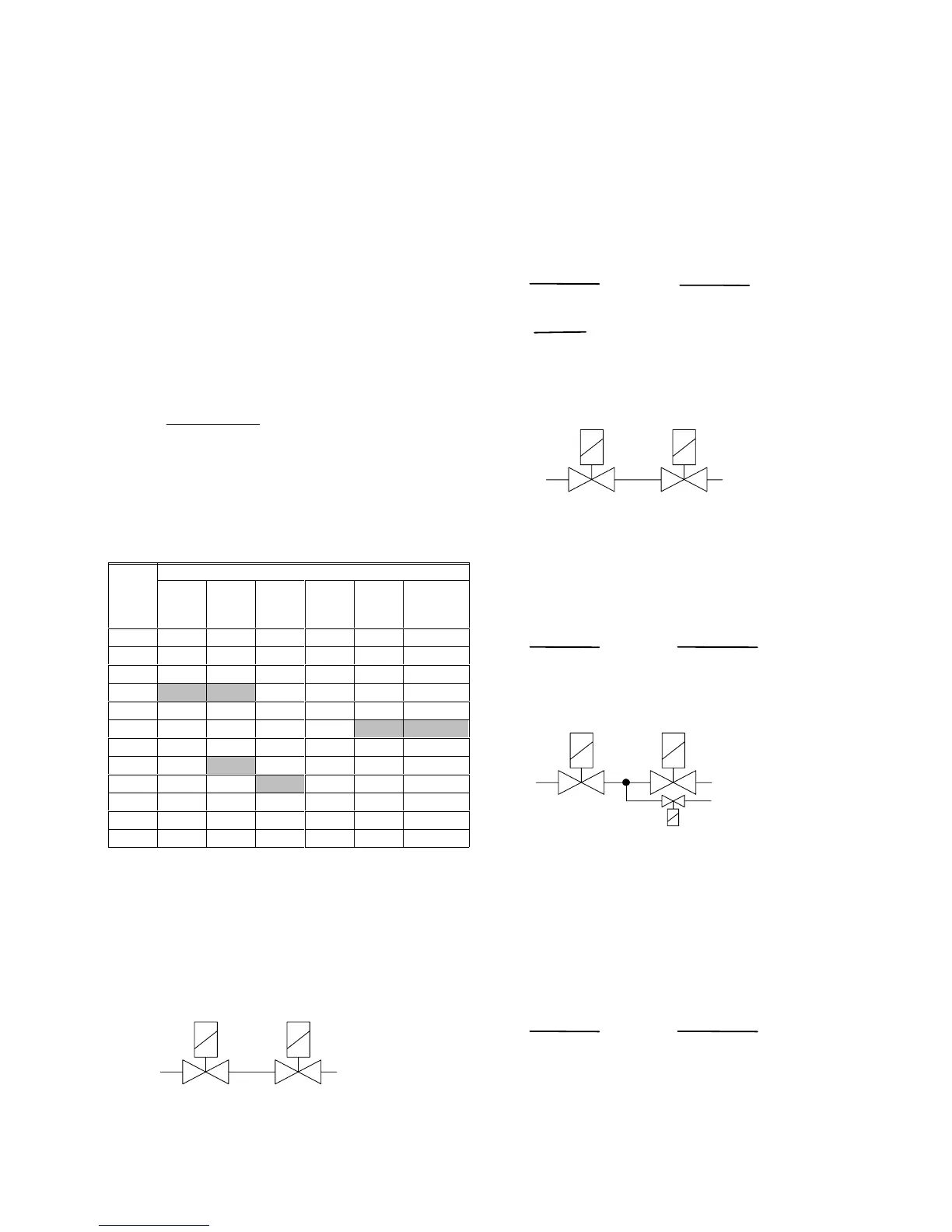

Table 4. Volumes in dm

3

for UGV valves

Vp

with length of

pipe L (including V1 and V2)

DN

Length between valves (m)

0 0,5 1 1,5 2 per

extra

meter

10T 0.06 0.10 0.14 0.18 0.22 0.08

15T 0.06 0.15 0.24 0.33 0.42 0.18

20T 0.12 0.28 0.43 0.59 0.74 0.31

25T 0.19 0.44 0.68 0.93 1.2 0.49

32T 0.69 1.1 1.5 1.9 2.3 0.80

40T 0.71 1.4 2.0 2.7 3.3 1.3

50T 1.3 2.3 3.3 4.2 5.2 2.0

65T 2.7 4.4 6.0 7.7 9.3 3.3

80T 2.9 5.4 7.9 10 13 5

65F 3.2 4.9 7.5 8.2 9.8 3.3

80F 4.4 6.9 9.4 12 14 5.0

100F 6.5 10.5 14.4 18 22 7.9

NOTE: T=Thread

F=Flange

V

0m

= volume of 2 valves with L= 0 m

IMPORTANT

ThetotalvolumeVphastobecalculatedwithall

volumes between the tested valves: internal

volumes of valves and all pipes

Calculation examples

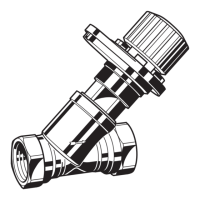

Example 1

Calculate the maximum pipe length between two 1 1/2” safety

valves when an A4021A valve proving system is used with a

test period (per valve) of 25 seconds.

Given: Pi = 75 mbar

Qm = 30 dm

3

/h

valve: 1 1/2”→DN40

To be calculated: L(max.) [m]

Calculation:

p ≡

2xPixVp

Qm

[s]

→

Tp ≡

2x150x4.4

60

=22[s]

Choose always a A40121 with a test time (per valve) higher

than the (minimum) calculated test time Tp.

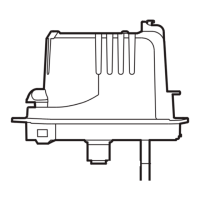

Example 3

Calculate the test period (per valve) in given situation.

Given: Pi = 150 mbar

Qm = 100 dm

3

/h

valve: VE4080A with 1 meter pipe (L1)

pilotvalve:VE4025with0.5meterpipe(L2)

To be calculated: Tp [s]

Calculation:

From Table 4. :

DN80T, L1=1m

DN25T, L2=0.5

Vp = V

1m + (

V

0.5m --

V

0m =

7.9 + (0.44 -- 0.19/2) = 8.25 dm

3

.

Loading...

Loading...