5

EN2R--9023 9705R0--NE

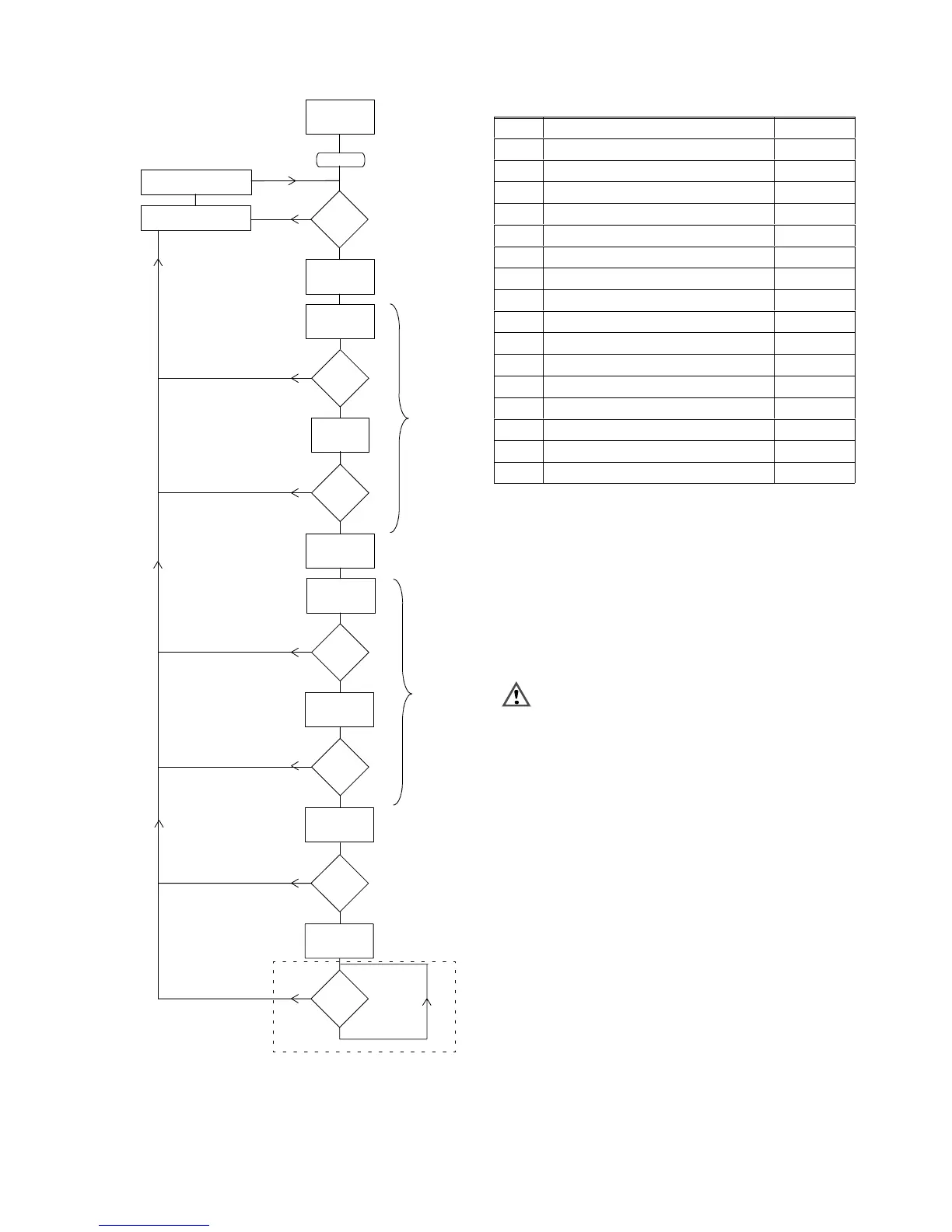

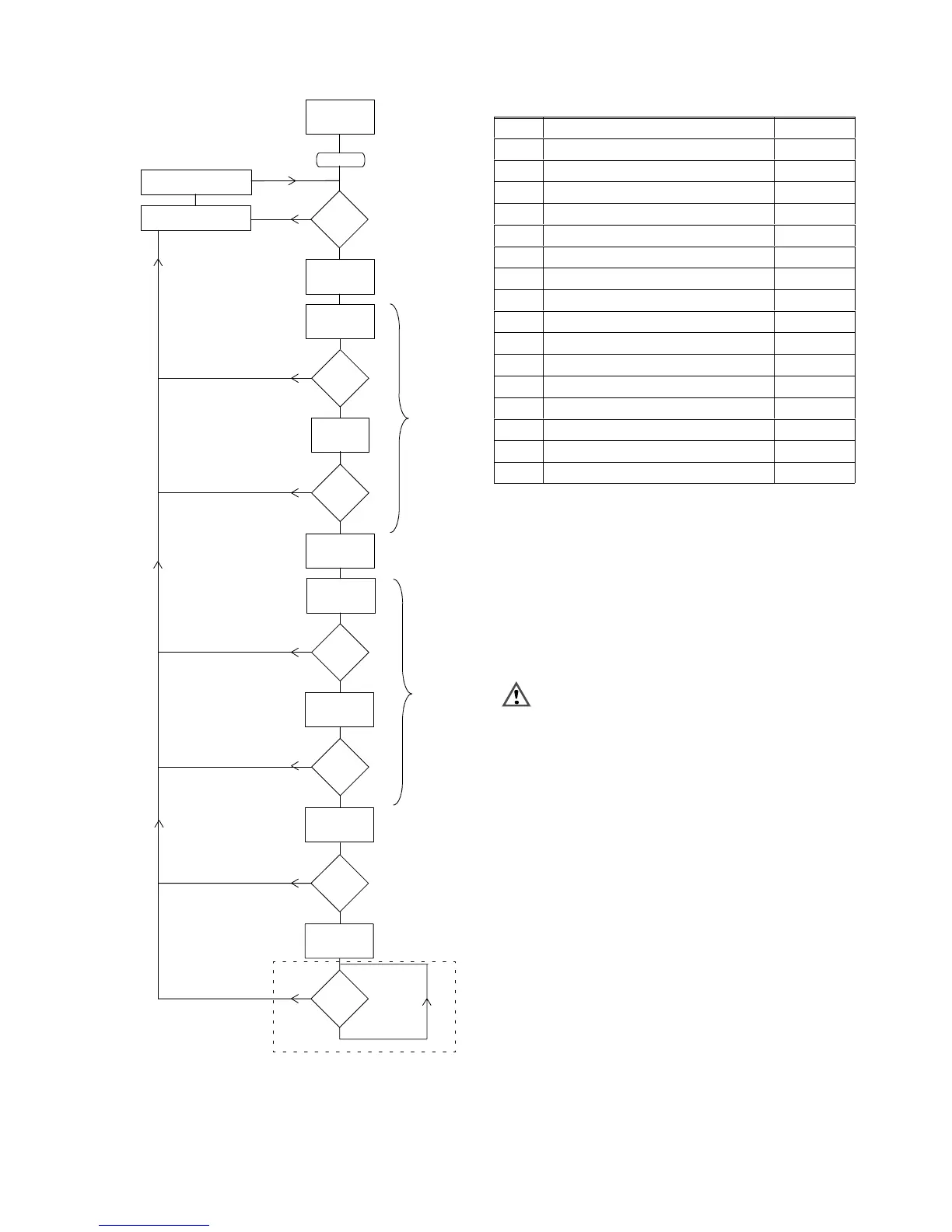

stabilization

time (3 sec.)

pressure

=low?

open valve 2

(5 sec.)

wait

(22 sec.)

open valve 1

(5 sec.)

pressure

=low?

stabilization

time (3 sec.)

pressure

=high?

wait

(22 sec.)

pressure

=high?

enable

ignition

controller

error + lock--out

no

no

no

no

yes

yes

yes

yes

test valve 1

test valve 2

self test

=OK?

yes

no

manual reset

1

2

3

4

5

6

7

8

10

11

12

13

pin 12

connected

enable

ignition

controller

yes

?

self test

=OK?

each 4 hours

no

no

yes

14

15

15

STANDBY

RUN

0

9

start

Fig. 5. General flow chart valve proving (given timings

for A4021A1002/1010

Table 2. Sequence timings for normal operation

State

Description Time

1)

(s)

0 STANBY infinite

2)

1 self--test + memory test <2

2 V2 powered 5

3 waiting for pressure to get low 3

4 wait 22

5 valve 1 powered 5

6 waiting for pressure to get high 3

7 wait 22

8 waiting for ignition controller to start indefinite

3)

9 RUN period, every 4 hours self--test

10 alarm, “error during test valve 1” indefinite

11 alarm, “valve 1 failing/leaking”

5)

indefinite

12 alarm, “error during test valve 2” indefinite

13 alarm, “valve 2 failing/leaking”

5)

indefinite

14 alarm, “error heat demand” indefinite

15 alarm, “self--test error”

4)

indefinite

1)

Timings depending on O.S. numbers, shown

A4021A1002/1010

2)

STANDBY can be infinite time period

3)

Depending on pre--purge and start--up time of the used

ignition controller

4)

When during the test sequence a fault is discovered by the

A4021, the system will go into a non--volatile lock--out and

generate an alarm “self test error” (see also

Troubleshooting section).The “self test error” also occurs

when the anti--recycle--counter reaches the value 10, see

also page 10 of the Product handbook.

5)

Leakage ≥ 0.1 % of maximum flow rate.

WARNING

No standard valve proving after lock--out of the

ignition controller.

Valve proving after lockout maybe required, this can

be achieved by special wiring diagrams. E.g. when a

DTSP switch is used to reset the ignition controller

and interrupting the heat--demand for the A4021A.

Loading...

Loading...