The Honeywell Braukmann D06G Valve is a high-quality pressure regulating valve designed to maintain a constant outlet pressure across a wide range of inlet supply pressures. It is particularly well-suited for applications involving potable water and irrigation where accurate pressure regulation is critical. The valve's design, which includes a wide outlet pressure range, high inlet pressure rating, and a compact form factor, offers significant flexibility in both installation and application scenarios.

One of the key usage features of the D06G valve is its non-corroding unitized cartridge, which encapsulates all the working parts. This design not only ensures durability and longevity but also simplifies maintenance, as the cartridge is easily replaceable. The valve offers a broad outlet pressure range, from 15 to 130 psi across all models, and can handle an impressive inlet pressure rating of up to 400 psi. This versatility makes it adaptable to various system requirements.

For enhanced system protection and performance, the D06G valve incorporates a built-in strainer. This strainer helps to filter out sediment and debris from the water flow, preventing them from reaching and potentially damaging the internal components of the valve or other downstream equipment. Additionally, the valve includes a thermal bypass mechanism, which is integral to all models. This feature helps to manage thermal expansion within the system, contributing to stable operation and preventing pressure build-up due to temperature fluctuations.

The physical design of the D06G valve is notably narrow, making it an excellent choice for installations where space is restricted. This compact footprint allows for greater flexibility in mounting locations, especially in tight or crowded utility areas. The valve also features a balanced seat construction, which is crucial for delivering superior pressure regulation. This design ensures that the valve can maintain a consistent outlet pressure even when there are variations in the inlet pressure or changes in flow demand.

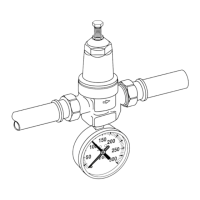

Connectivity is another practical aspect of the D06G valve. Both the inlet and outlet ports are internally threaded NPT, providing a standard and secure connection point for plumbing. Furthermore, these ports are externally threaded for use with union assemblies, offering additional flexibility for installation and future servicing. To facilitate system monitoring, all models of the D06G valve are equipped with gauge taps, allowing for easy attachment of pressure gauges to verify inlet and outlet pressures.

From a maintenance perspective, the D06G valve is designed for straightforward servicing. The unitized cartridge, which contains the diaphragm, valve seat, strainer, and disk, can be easily removed and replaced. This modular approach significantly reduces the time and effort required for repairs, as technicians can simply swap out the entire cartridge rather than disassembling and repairing individual components. The process for replacing the cartridge involves closing the supply valve, relieving downstream pressure, loosening the locking screw, and removing the bonnet, spring, and protection washer. The cartridge can then be carefully removed using screwdrivers as levers. After cleaning the valve's interior, a new cartridge, along with a new U-seal (provided in the repair kit), can be installed.

Cleaning the built-in strainer screen is also a simple procedure. It involves closing the supply valve, relieving downstream pressure, and then removing the strainer cup using a service tool. The strainer and its support can then be removed, cleaned, and reassembled. The design ensures that the U-seal remains in place during this process, simplifying reassembly.

Adjusting the outlet pressure of the D06G valve is a user-friendly process. Although the valve is factory-set at 60 psi (no flow), adjustments can be made by first closing the supply shutoff and opening a downstream faucet to relieve pressure. A pressure gauge can then be installed, and after closing the faucet and opening the supply valve, the locking screw can be loosened. Turning the adjusting knob clockwise increases pressure, while turning it counterclockwise decreases pressure. A slight downstream flow is recommended when decreasing pressure to ensure accurate adjustment. Once the desired pressure is set, the locking screw is tightened to secure the setting.

The D06G valve operates on a balanced, direct-acting pressure-regulating principle. The spring force holds the valve in an open position until the downstream pressure, sensed by a port, exerts sufficient force on the underside of the diaphragm to close the valve. When downstream pressure drops due to demand, the force on the diaphragm decreases, causing the valve to open again. Manual adjustments to the knob modify the spring force, thereby setting the desired outlet pressure. Once set, the D06G automatically regulates to maintain this pressure, adapting to varying inlet pressures and downstream flow demands. This robust and adaptable design makes the Honeywell Braukmann D06G Valve a reliable component for maintaining consistent water pressure in a variety of applications.