MERLIN NX IP AND MST/TP VAV CONTROLLER - INSTALLATION INSTRUCTIONS

EN1Z-1076GE51 R0722 10

The actuator mounts directly onto the VAV box damper

shaft and has up to 44 in-lb. (5 Nm) torque, 90-degree

stroke, and 108 second timing at 50 Hz and 90 second

timing at 60 Hz.

The actuator is shipped with two mechanical end limit set

screws to control the amount of rotation from 12° to 95°.

These set screws must be securely fastened in place. To

ensure tight closing of the damper, the shaft adapter has a

total rotation stroke of 95°.

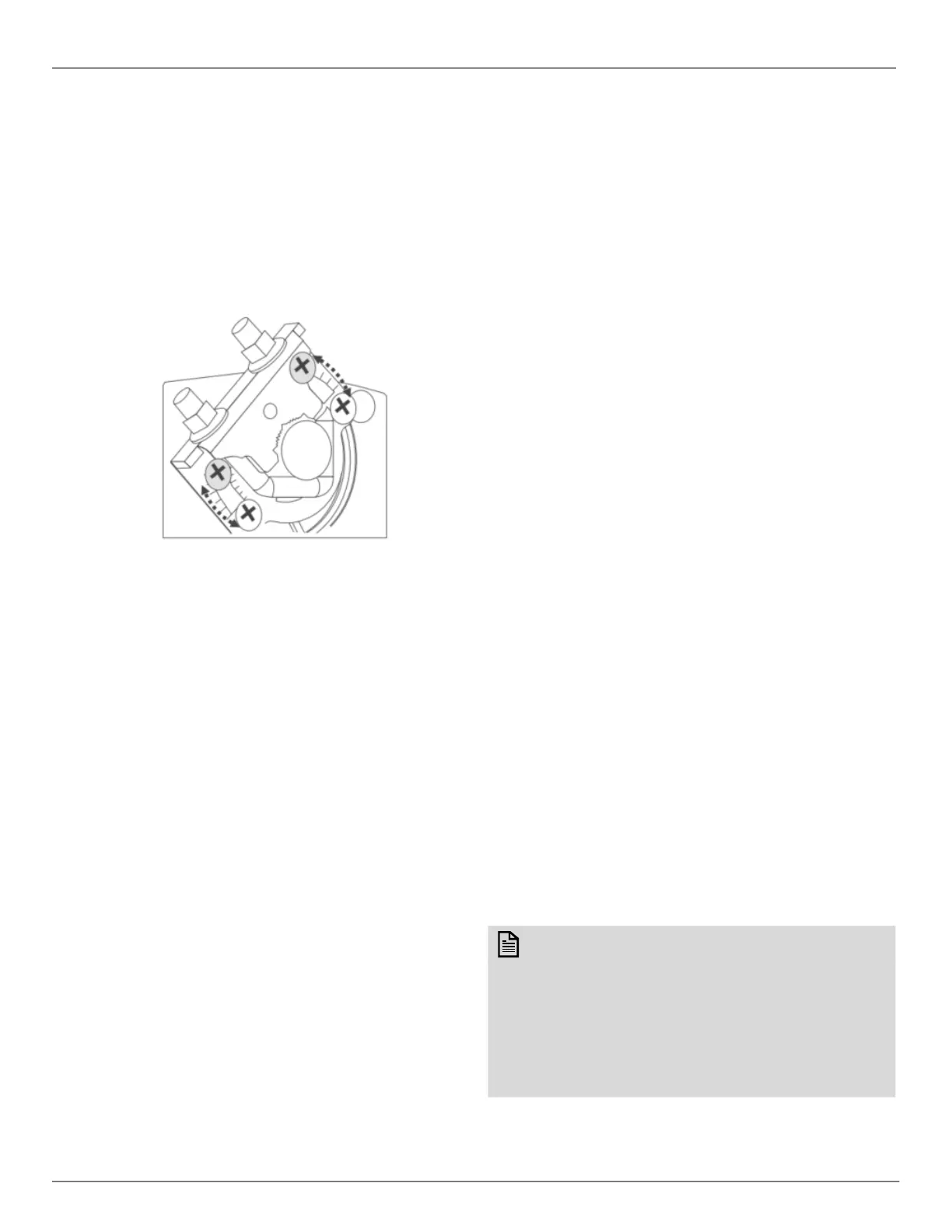

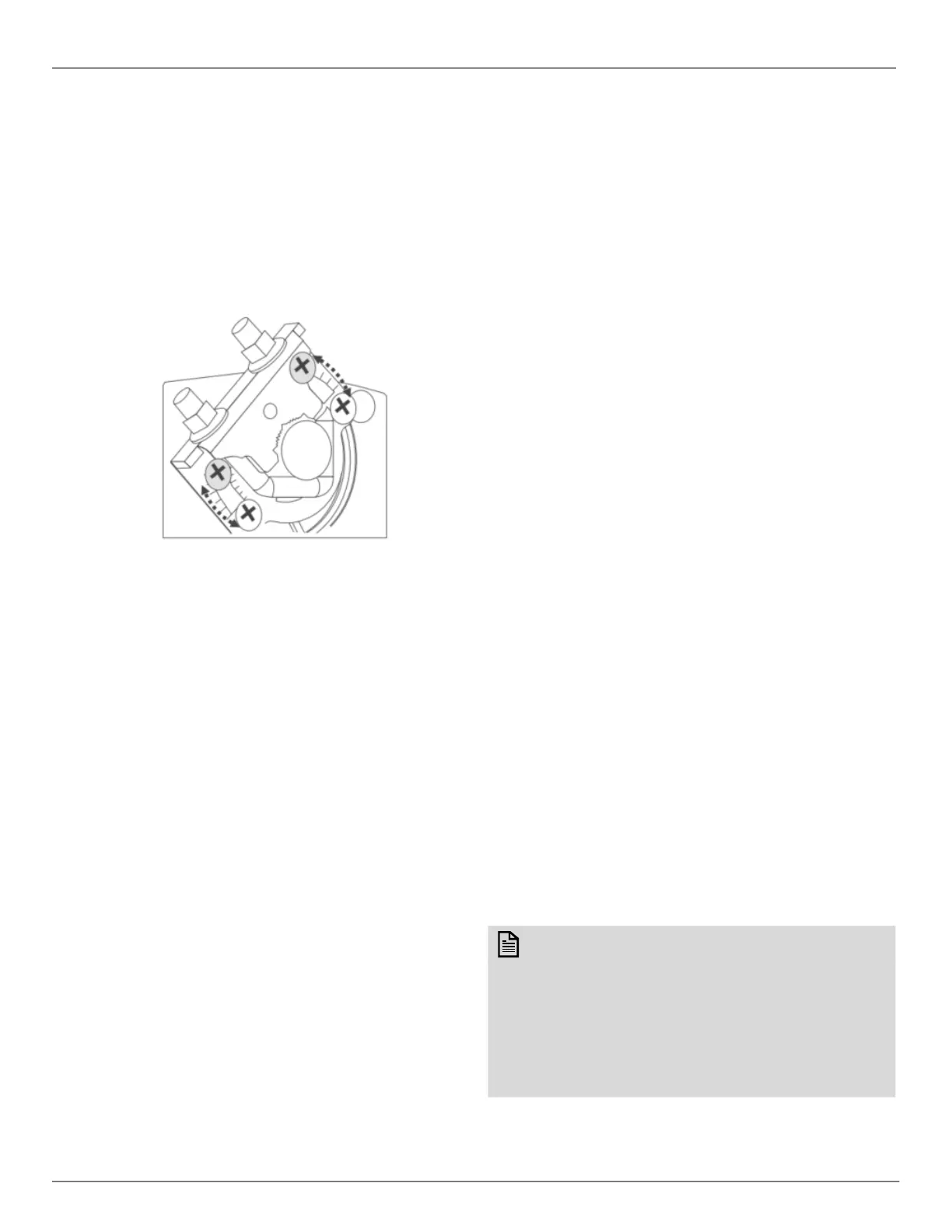

Fig. 10. Setting the mechanical end limits

NOTE: The actuator is shipped with the mechanical end-

limit set screws set to 95° of rotation.

Adjust the two set screws closer together to reduce

the rotation travel. Each “hash mark” indicator on

the bracket represents approximately 6.5° of rota-

tion per side.

The Declutch button, when pressed, allows you to

rotate the universal shaft adapter.

The unit is shipped with the actuator set to rotate open in

the clockwise (CW) direction to a full 95°. The extra 5°

ensures a full opening range for a 90⁰ damper. The

installation procedure varies depending on the damper

opening direction and angle:

1. If the damper rotates clockwise (CW) to open, and the

angle of the damper open-to-closed is 90°:

a. Manually open the damper fully (rotate clockwise).

b. Using the Declutch button, rotate the universal shaft

adapter fully clockwise.

c. Mount the actuator to the VAV damper box and shaft.

d. Tighten the two bolts on the centering clamp (8 mm

wrench; 70 lb.-in. [8 Nm] torque). When the actuator

closes, the damper rotates CCW 90 degrees to fully

close.

2. If the damper rotates clockwise (CW) to open, and the

angle of the damper open-to-closed is 45 or 60 degrees:

a. Manually open the damper fully (rotate clockwise).

b. The actuator is shipped with the mechanical end limits

set at 95 degrees. Adjust the two mechanical end-limit

set screws to provide the desired amount of rotation.

Adjust the two set screws closer together to reduce the

rotation travel.

c. Tighten the two mechanical end-limit screws (Phillips #2

screwdriver; (26.5-31 lb.-in. [3.0-3.5 Nm] torque).

d. Using the Declutch button, rotate the universal shaft

adapter fully clockwise.

e. Mount the actuator to the VAV damper box and shaft.

f. Tighten the two bolts on the centering clamp (8 mm

wrench; 70 lb. in. [8-10 Nm] torque).

g. When the actuator closes, the damper rotates CCW

either 45 or 60 degrees to fully close.

3. If the damper rotates counterclockwise (CCW) to open,

and the angle of the damper open-to-closed is 90

degrees:

a. Manually open the damper fully (rotate counterclock-

wise).

b. Using the Declutch button, rotate the universal shaft

adapter fully counterclockwise.

c. Mount the actuator to the damper box and shaft.

d. Tighten the two bolts on the centering clamp (8 mm

wrench; 70 lb.-in. [8Nm] torque). When the actuator

closes, the damper rotates CW 90 degrees to fully close.

4. If the damper rotates counterclockwise (CCW) to open,

and the angle of the damper open-to-closed is 45 or 60

degrees:

a. Manually open the damper fully (rotate counterclock-

wise).

b. The actuator is shipped with the mechanical end limits

set at 95 degrees. Adjust the two mechanical end-limit

set screws to provide the desired amount of rotation.

Adjust the two set screws closer together to reduce the

rotation travel.

c. Tighten the two mechanical end-limit screws (Phillips #2

screwdriver; (26.5-31 lb.-in. [3.0-3.5 Nm] torque).

d. Using the Declutch button, rotate the universal shaft

adapter fully counter-clockwise.

e. Mount the actuator to the VAV damper box and shaft.

f. Tighten the two bolts on the centering clamp (8 mm

wrench; 70 lb.-in. [8Nm] torque).

g. When the actuator closes, the damper rotates CW either

45 or 60 degrees to fully close.

Airflow Sensor Connection

Connect the air flow pickup to the two restrictor ports on the

controller.

NOTE:

Use 1/4 in. (6 mm Outside diameter and 5 mm inner

diameter), with a 3/64 in. (1 mm) wall thickness, ple-

num-rated 1219 FR (94V-2) tubing.

You should always use a fresh cut on the end of the

tubing that connects to the air flow pickups and the

restrictor ports on the controller. Secure the connec-

tion using a zip tie (procured locally).

Loading...

Loading...