EC7830A, RM7830A, EC7850A, RM7850A 7800 SERIES RELAY MODULES

13 32-00198—01

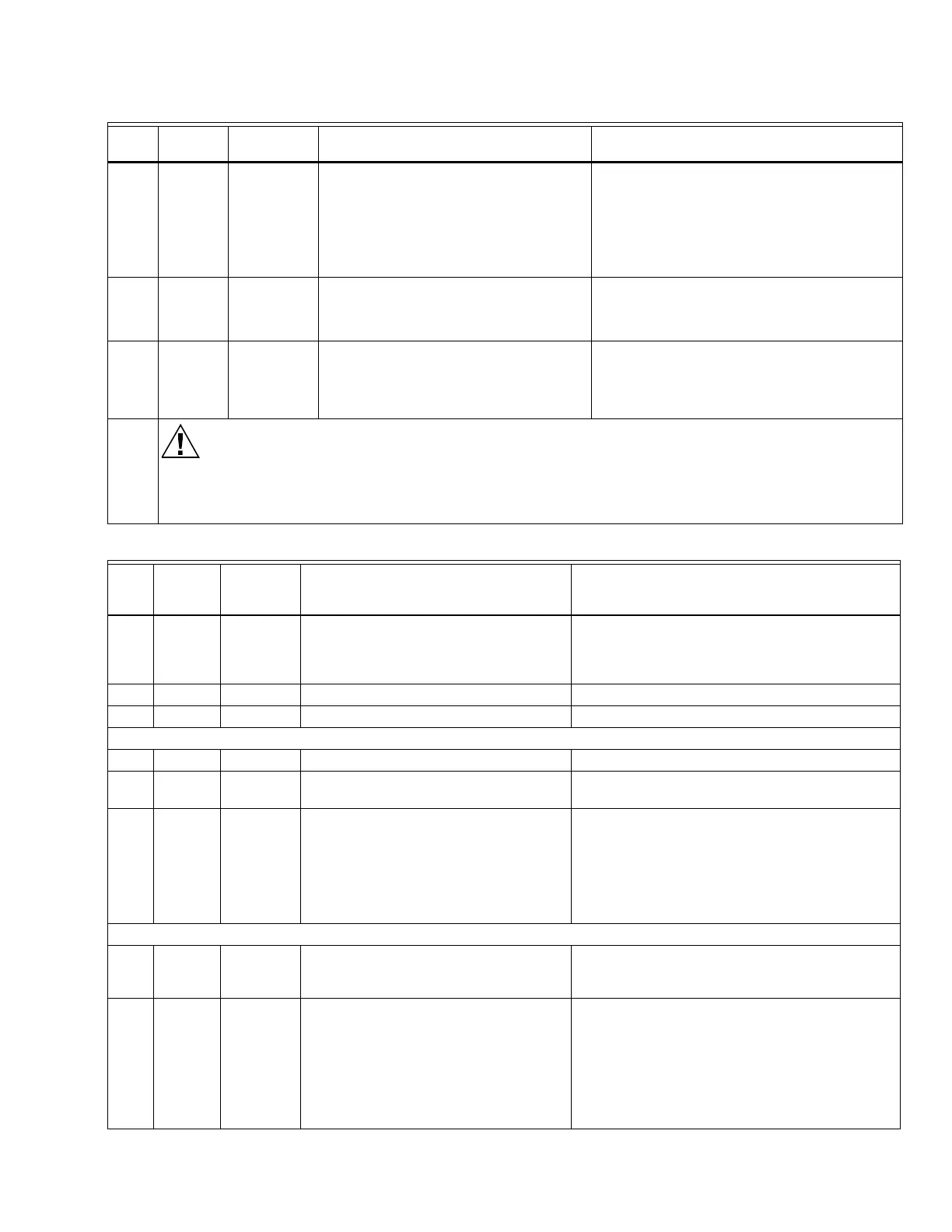

85-8 — 1. Ignition spark (if ignition trans-

former is connected to terminal 8).

2. Automatic pilot valve opens (if

connected to terminal 8).

NOTE: Refer to wiring diagram of sys-

tem being tested.

1. Watch for spark or listen for buzz.

a. Ignition electrodes are clean.

b. Ignition transformer is okay.

2. Listen for click of fee head of valve for

activation.

a. Actuator, if used.

b. Pilot valve.

9 5-21 — Same as test no. 8 for connections to

terminal 8. If using direct spark ignition,

check the first stage fuel valve(s) instead

of the pilot valve.

Same as test no. 8. If using direct spark

ignition, check the first stage fuel valve(s)

instead of the pilot valve.

10 5-9 — Automatic fuel valve(s) open(s).

If using direct spark ignition on a model

with intermittent pilot on terminal 21,

check the optional second stage fuel

valve, if used.

1. Listen for and observe operation of the

main fuel valve(s) and actuator(s).

2. Valve(s) and actuator(s).

Final

Equipment Damage Hazard.

Failure to remove jumpers can damage equipment.

After completing these tests, open the master switch and remove ALL test jumpers from the subbase

terminals. Then remove bypass jumpers from the low fuel pressure limits (if used).

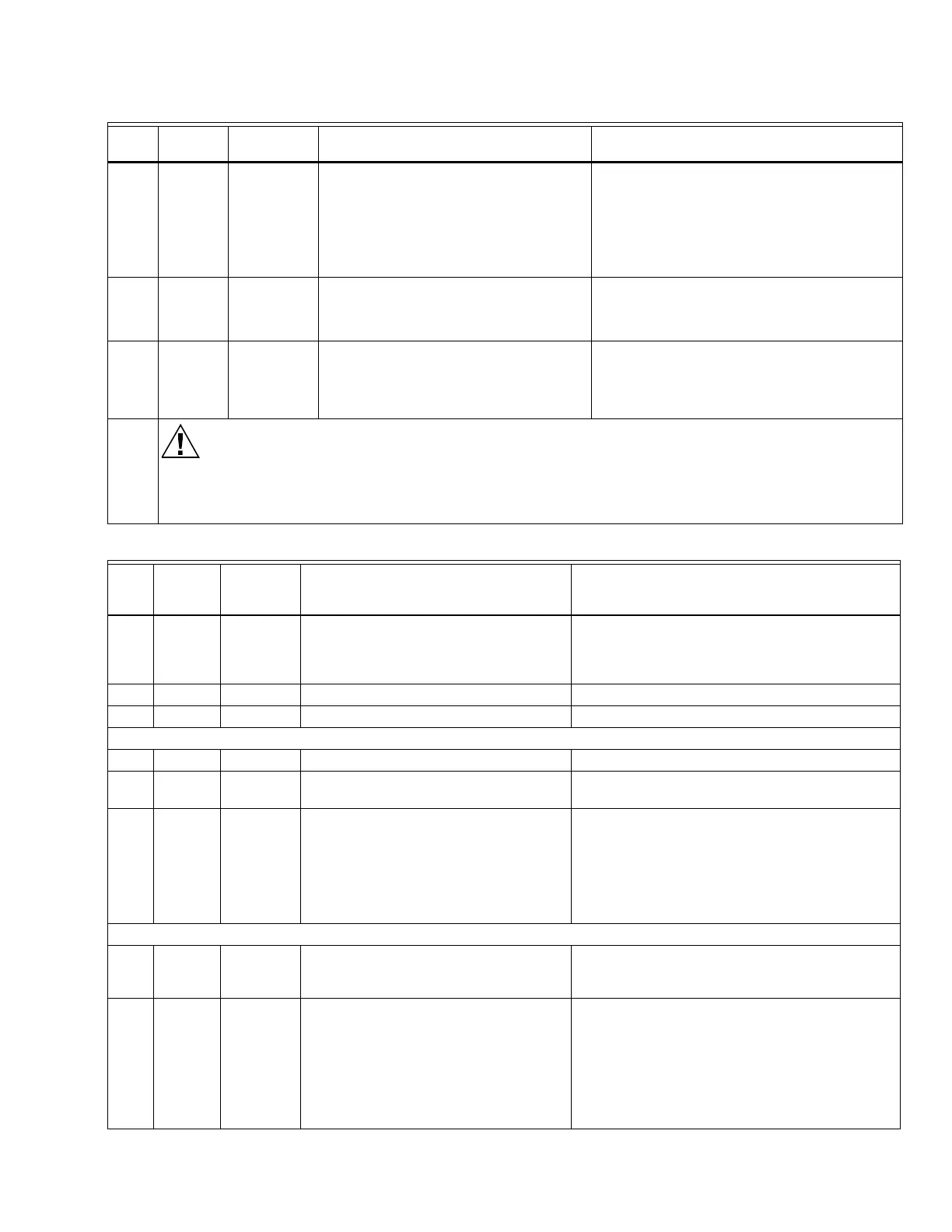

Table 6. EC/RM7850A Static Checkout.

Test

No.

Test

Jumper

s Voltmeter Normal Operation If Operation is Abnormal, Check These Items

1 None 4-2 Line voltage at terminal 4. 1. Master switch.

2. Power connected to the master switch.

3. Overload protection (fuse, circuit breaker,

etc.) did not open the power line.

2 None 17-2 Line voltage at terminal 17. Preignition interlocks.

3 4-16 — Alarm (if used) turns on. Alarm.

NOTE: Disconnect horn at this time (if used).

4 4-16 2-20 Line voltage at terminal 20. Limits in Lockout Circuit.

5 4-16 2-6 Line voltage at terminal 6. 1. Recycle limits.

2. Burner control.

64-16

5-4

2-7 1. Fan (Burner Motor or Blower)

starts.

2. Line voltage at terminal 7.

1. Fan circuit.

a. Manual fan switch.

b. Fan power supply, overload protection

and starter.

c. Fan.

2. Running limits of Airflow Switch (LD2)

input.

NOTE: Remove jumpers and re-connect alarm (if used).

7 4-10 — Ignition spark (if ignition transformer is

connected to terminal 10).

1. Watch for spark or listen for buzz.

a. Ignition electrodes are clean.

b. Ignition transformer is okay.

8 4-8 — Ignition spark (if ignition transformer is

connected to terminal 8).

Automatic pilot valve opens (if

connected to terminal 8).

Refer to wiring diagram of system being

tested.

1. Watch for spark or listen for buzz.

a. Ignition electrodes are clean.

b. Ignition transformer is okay.

2. Listen for click of fee head of valve for

activation.

a. Actuator, if used.

b. Pilot valve.

Table 5. EC/RM7830A Static Checkout. (Continued)

Test

No.

Test

Jumpers Voltmeter Normal Operation

If Operation is Abnormal, Check the Items

Listed Below

Loading...

Loading...