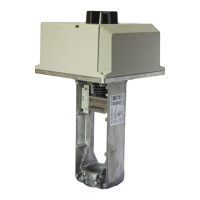

ML6984, ML7984 SERIES 4000 DIRECT COUPLED VALVE ACTUATORS

Automation and Control Solutions

Honeywell International Inc.

1985 Douglas Drive North

Golden Valley, MN 55422

customer.honeywell.com

® U.S. Registered Trademark

© 2016 Honeywell International Inc.

95C-10939—11 M.S. Rev. 09-16

Printed in United States

TROUBLESHOOTING

TYPICAL SPECIFICATIONS

Valve Actuators shall mount directly to the bonnet of the

valve, and shall be self-contained and self adjusting.

Direct coupled valve actuators shall be 24° Vac or 28° Vdc

power, available with floating or modulating control signal

inputs. Actuator shall be usable with common power

supply for multiple actuators and controllers.

Position feedback voltage/pilot duty auxiliary switch kit,

mounting adaptor, high temperature kits, and resistor kits

for multiple actuator application shall be optional

accessories for direct coupled valve actuators.

Direct coupled valve actuators shall have a minimum

performance rating of 50,000 full stroke cycles plus

1,000,000 repositions documented in the product

literature.

Direct coupled valve actuators shall be manufactured by

the same company as manufacturers of the valves.

Symptom Possible Causes Actions

Valve seat leaks or will not close

properly

Wrong actuator used and/or system head pressure too

high

1) Check valve close-off rating

2) Check voltage at actuator terminals

Actuator not properly installed Ensure valve stem is fully threaded into brass drive shaft and locked

in place with the set screw

Incorrect DIP switch settings Check against Product Instruction Sheet

Noisy Motor Bearing failed due to overheat 1) Check for excessive temperature and replace complete actuator

2) Use high temperature kit (43196000-001)

Brushes worn out Check for excessive cycling and replace actuator

Motor

overheats/smoke/component

burn-out

Current sensing circuit failed or electronic components

failed

Replace actuator. Make sure:

1) Correct actuator used

2) Properly installed

3) Do not operate actuator before mounting on valve supply

4) Proper voltage supply

ML will not respond LED (on):

Incorrect DIP switch settings Check against Product Instruction Sheet

No control signal present Check controller

Incorrect wiring connections Check against Product Instruction Sheet

Internal time delay Allow at least 1/2 - 1 second for the ML to respond

LED (off):

No or low power supply Check voltage on T5 and T6 terminals

Error mode (gearbox damage) 1) Check power supply

2) Check calibration cycle

3) Valve stroke length less than 1/2 in. or greater than 1-1/4 in.

4) Reset device by a momentary disconnect of power at T5 and T6

Vdc/mA signal drops when

connected to ML

ML7984 in mA mode with voltage input Change DIP switch setting

Signal degradation due to incompatible load impedance Output and ML input impedance specifications

Actuator yoke corrodes Galvanic reaction from dissimilar metals if

SS U-bolt used with aluminum yoke

Replace U-bolt with galvanized U-bolt and nuts

Floating Actuator position “drifts”

when used with building

automation system

Mismatch between actuator resolution

(30 steps) and BAS controller

1) Read actual valve position using 272630D feedback module

2) Rewire actuator for 3-wire control

3) Program daily valve reset.

Loading...

Loading...