MPD Operating Manual

18

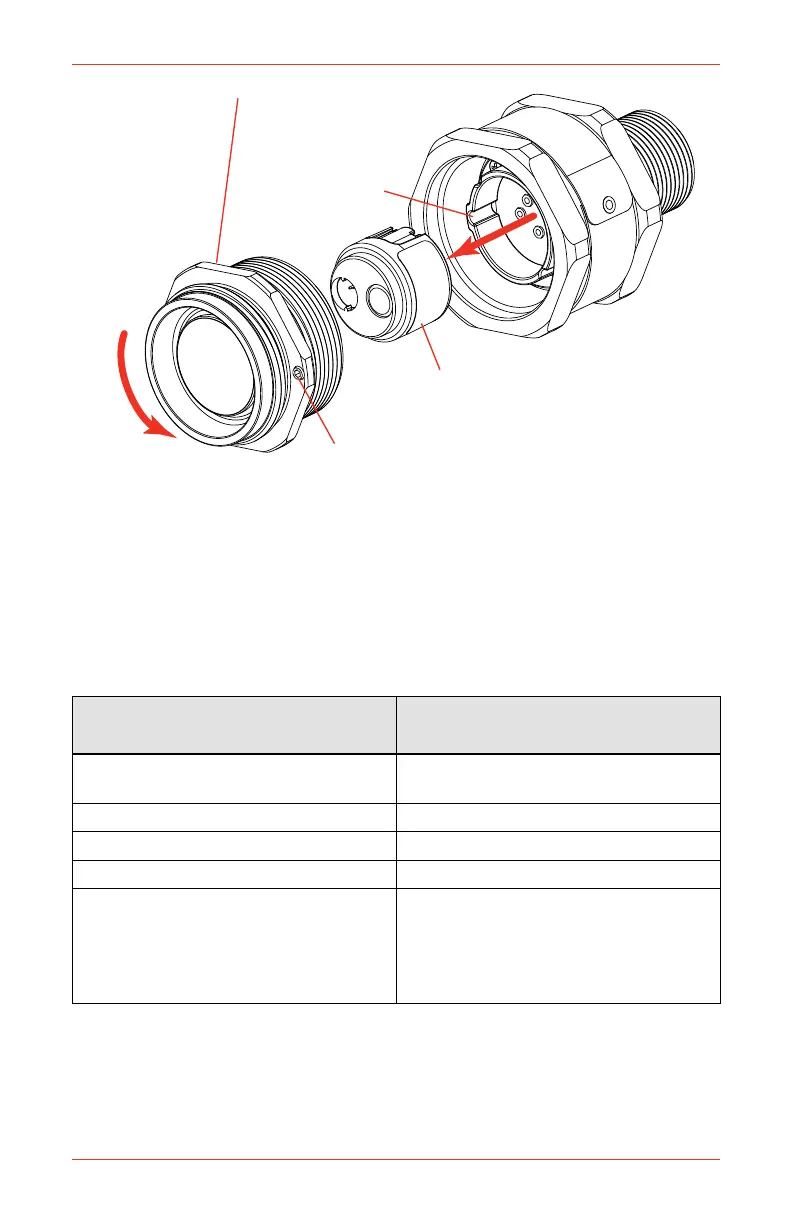

Cell Alignment Slot

Sensor Cell

IR or Cat Bead

Sensor Retainer

and Locking Screw

Internal O-ring

(critical to performance times)

Figure 9. Replacing Plug In Sensor

5. Faults

The following table provides a list of possible faults related to the sensor together

with possible causes and remedies.

Fault Cause/Remedy

Sensor reads non-zero all the time

Gas could be present, ensure there is no

combustible gas in the atmosphere.

Sensor reads non zero when no gas is present Adjust the zero of the control system.

Sensor reads low when gas is applied Adjust the span of the control system.

Sensor reads high when gas is applied Adjust the span of the control system.

Sensor reads zero when gas is applied

• check the wiring.

• check that the dust protection cap has been

removed.

• check that the sinter is not obstructed.

• replace the sensor if poisoning is suspected.

In the event of exposure to contaminant, e.g. silicones or silicone based products,

or prolonged exposure to high concentration of gas, the sensor should be operated

for 24 hours in a clean environment and then recalibrated.

If the sensor is found to be faulty, or cannot be calibrated, the complete sensor

must be discarded and replaced.

Loading...

Loading...