RM7898A 7800 SERIES VALVE PROVING PRIMARY RELAY MODULES

32-00209-03 12

*Replace jumper wire with ammeter and verify loads to component ratings.

VALVE PROVING SYSTEM

The Valve Proving System feature provides a systematic way

of testing the valve seat integrity to assure the valves are in

the closed state whenever the sequence of operation

requires them to be closed. It is designed to detect a leak

greater than 0.1% of the burner input capacity. For example,

a 10 million Btu/hr natural gas-fueled burner would have a

fuel input capacity of approximately 1,000 ft

3

/hr. A leak rate

greater than 0.1% of 1,000 ft

3

/hr or 1 ft

3

/hr in either valve

will be detected with the Valve Proving System. Smaller

leaks will not be detected.

At commissioning time, the Valve Proving System may be

scheduled to occur at one of five different times: Never,

Before, After, Both, and Split.

Never—Device default as received: in this case Valve

Proving does not occur.

Before—Valve Proving occurs concurrent with Pre-

Purge.

After—Valve Proving occurs after the Run state before

the internal Safety Relay dropout state and concurrent

with Post Purge (if configured).

Both—Valve Proving occurs at both times Before and

After noted above.

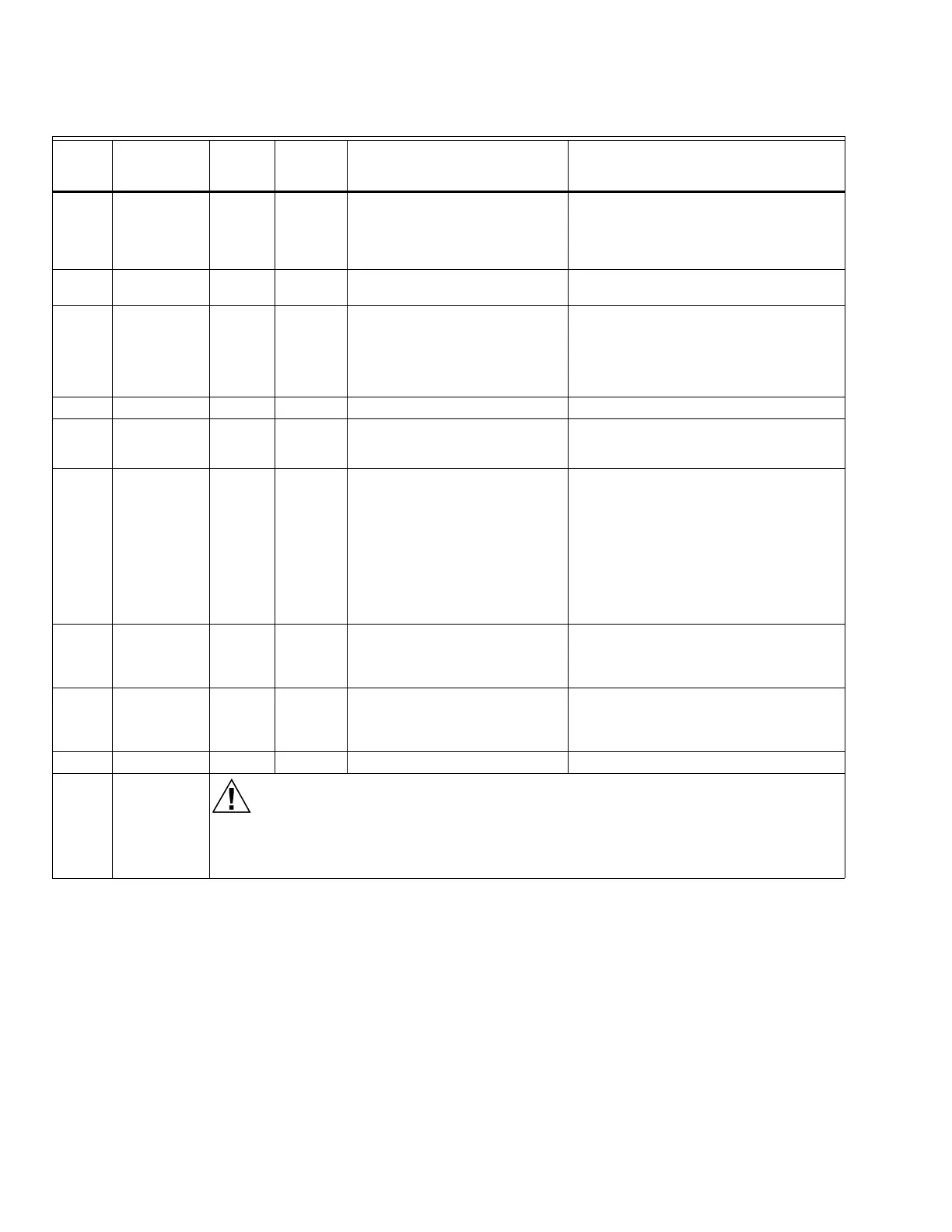

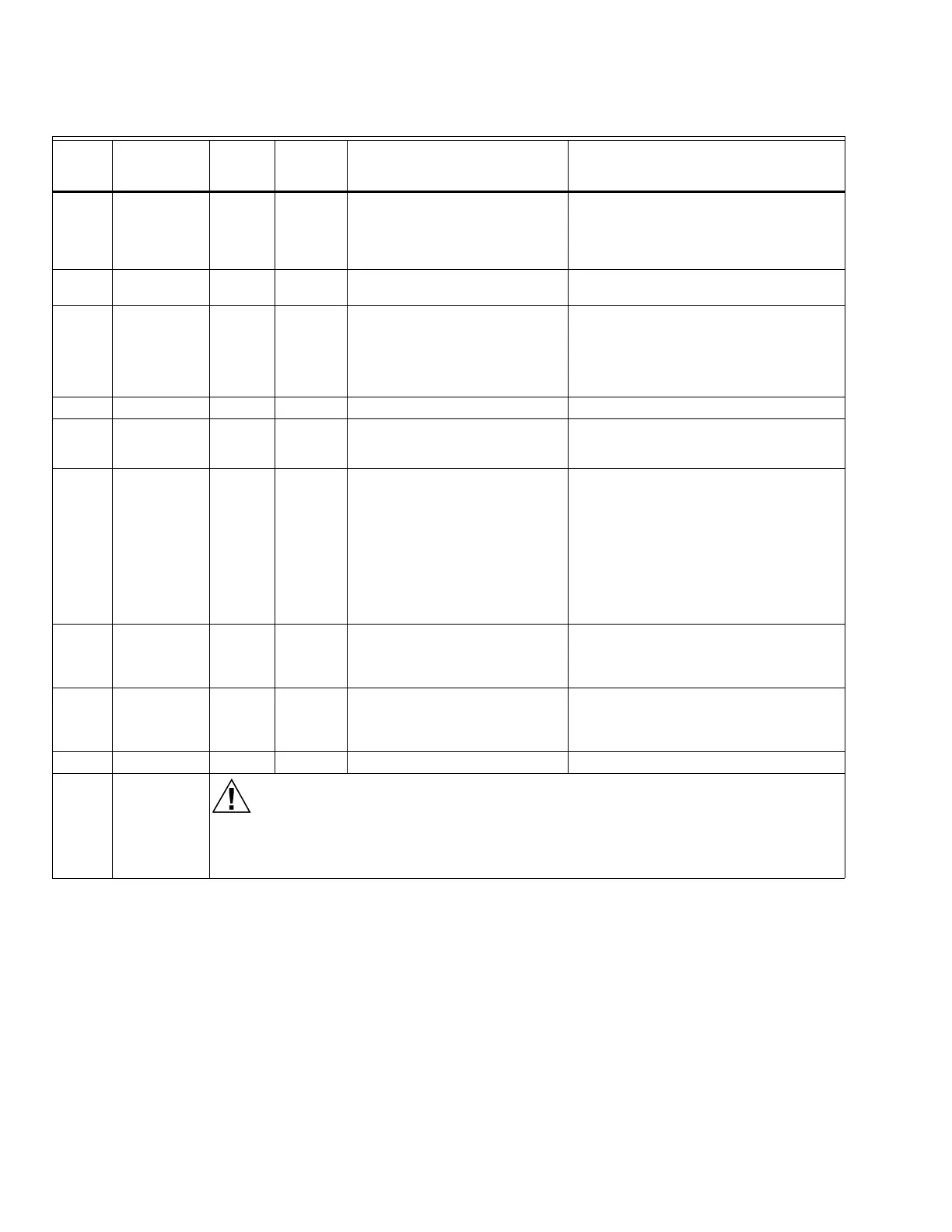

Table 6. Static Checkout.

Test

Numbe

r

Relay

Module

Model

Test

Jumper

s

Voltmete

r Normal Operation

If Operation is Abnormal,

Check Items Listed Below

1 All None 5-L2 Line voltage at terminal 5. 1. Master switch.

2. Power connected to master switch.

3. Overload protection (fuse, circuit

breaker, etc.) has not opened power

line.

2All None6-L2 or

17-L2

Line voltage at terminal 6 or 17.

For Valve Proving.

1. Limits.

2. Burner controller.

3 All 4-5 7-L2 1. Burner motor (fan or blower)

starts.

2. Line voltage at terminal 7

within 10 seconds.

1. Burner motor circuit.

a. Manual switch of burner motor.

b. Burner motor power supply,

overload

protection and starter.

c. Burner motor.

4 All 20-L2 Line voltage at Terminal 20 Pre-Ignition Interlocks.

5 All 5-10* — 1. Ignition spark (if ignition

transformer is connected to

terminal 10).

1. Watch for spark or listen for buzz.

a. Ignition electrodes are clean.

b. Ignition transformer is okay.

6All 5-8*— 1. Ignition spark (if ignition

transformer is connected

to terminal 8).

2. Automatic pilot valve

opens

(if connected to terminal

8).

NOTE: Refer to wiring diagram

of system being tested.

1. Watch for spark or listen for buzz.

2. Listen for click or feel head of valve for

activation.

a. Actuator if used.

b. Pilot valve.

7All 5-9*— Automatic fuel valve(s) open(s).

If using direct spark ignition,

check first stage fuel valve(s)

instead of pilot valve.

Same as test 6. If using direct spark

ignition, check first stage fuel valve(s)

instead of pilot valve.

8 All 5-21* — Automatic second stage main

fuel valve(s) open(s).

1. Listen for and observe operation of

second stage main fuel valve(s) and

actuator(s).

2. Valve(s) and actuator(s).

9 All 5-3 — Alarm (if used) turns on. 1. Alarm.

Final All

Equipment Damage Hazard.

Can cause equipment damage.

After completing these tests, open master switch and remove all test jumpers from

subbase terminals. Also remove bypass jumpers, if used, from low fuel pressure limits.

Loading...

Loading...