AUTOMATIC OPPOSED BLADE DAMPERS (AOBD)

11 68-0246

SERVICE

Checking Damper Blades

Occasionall

damper blades stick while openin

or closin

.

The problem ma

be caused b

a worn motor switch or

bindin

damper blades. To locate the problem:

1.

Remove the electric actuator enclosure, if necessar

.

2.

Separate the crank arm from the motor shaft usin

a 1-

16 Allen wrench.

3.

Usin

our hand, open and close the damper blades

several times b

pushin

and pullin

the crank shaft:

a. If linka

e and damper blades move freel

, the

are

workin

correctl

.

b. If linka

e and damper blades re

uire effort to open

or close, replace the damper and repeat step 2.

4.

If the damper blades still re

uire considerable effort to

open or close, check that the damper is sized correctl

and that there is no pressure on the damper blades. If

the damper is not sized correctl

, replace the old

damper with a correctl

-sized damper.

5.

Attach the crank arm to the motor drive shaft.

6.

If the damper blades continue to stick while openin

or

closin

, refer to the Installation Instruction to ensure the

mountin

screws are installed correctl

.

7.

Be sure the damper blades close full

b

shortin

termi-

nals 5 and 6. If there is a

ap between damper blades:

a. Loosen the crank arm from the motor drive shaft

usin

a 1-16 Allen wrench.

b. Manuall

close the

ap between the damper blades.

c. Ti

hten the crank arm to the motor drive shaft usin

a 1-16 Allen wrench.

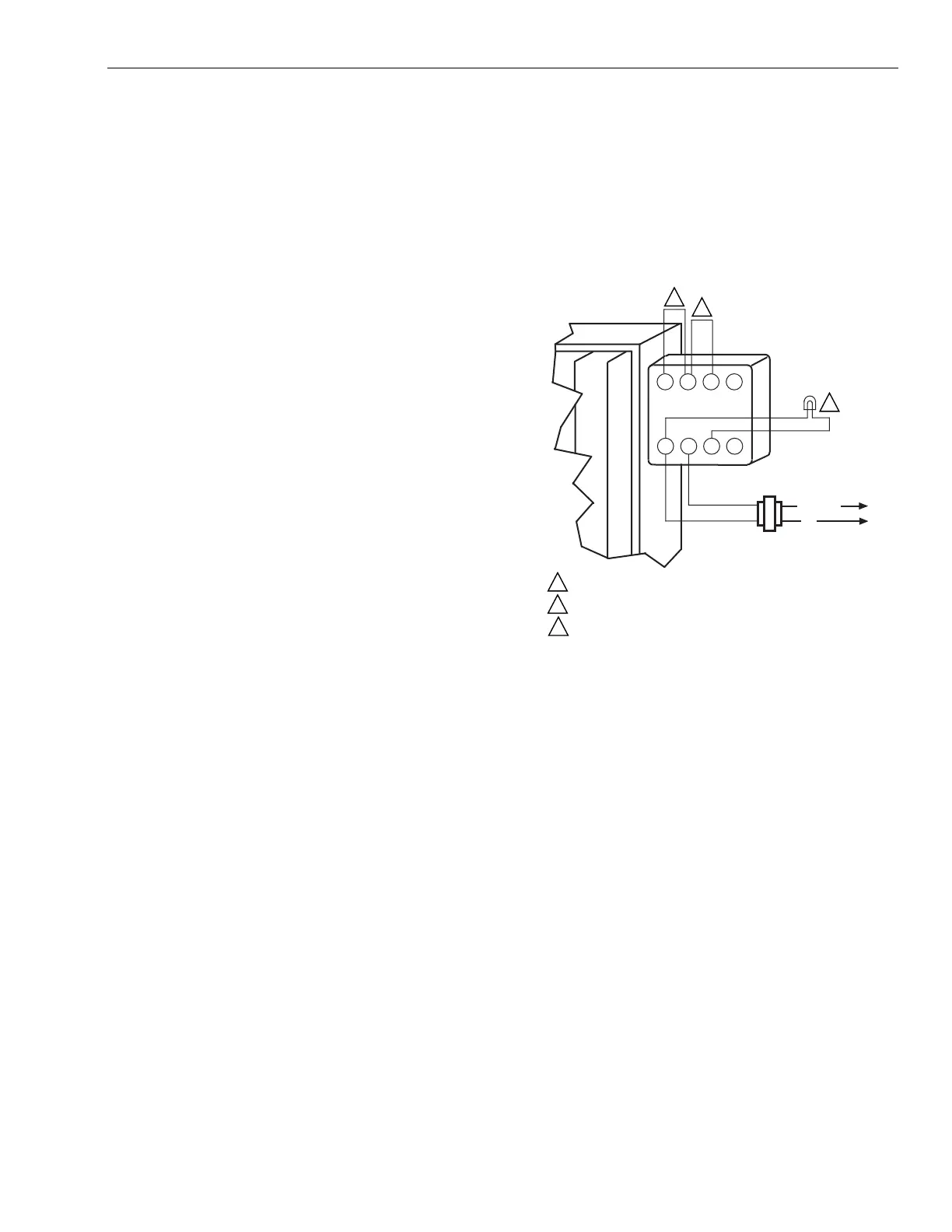

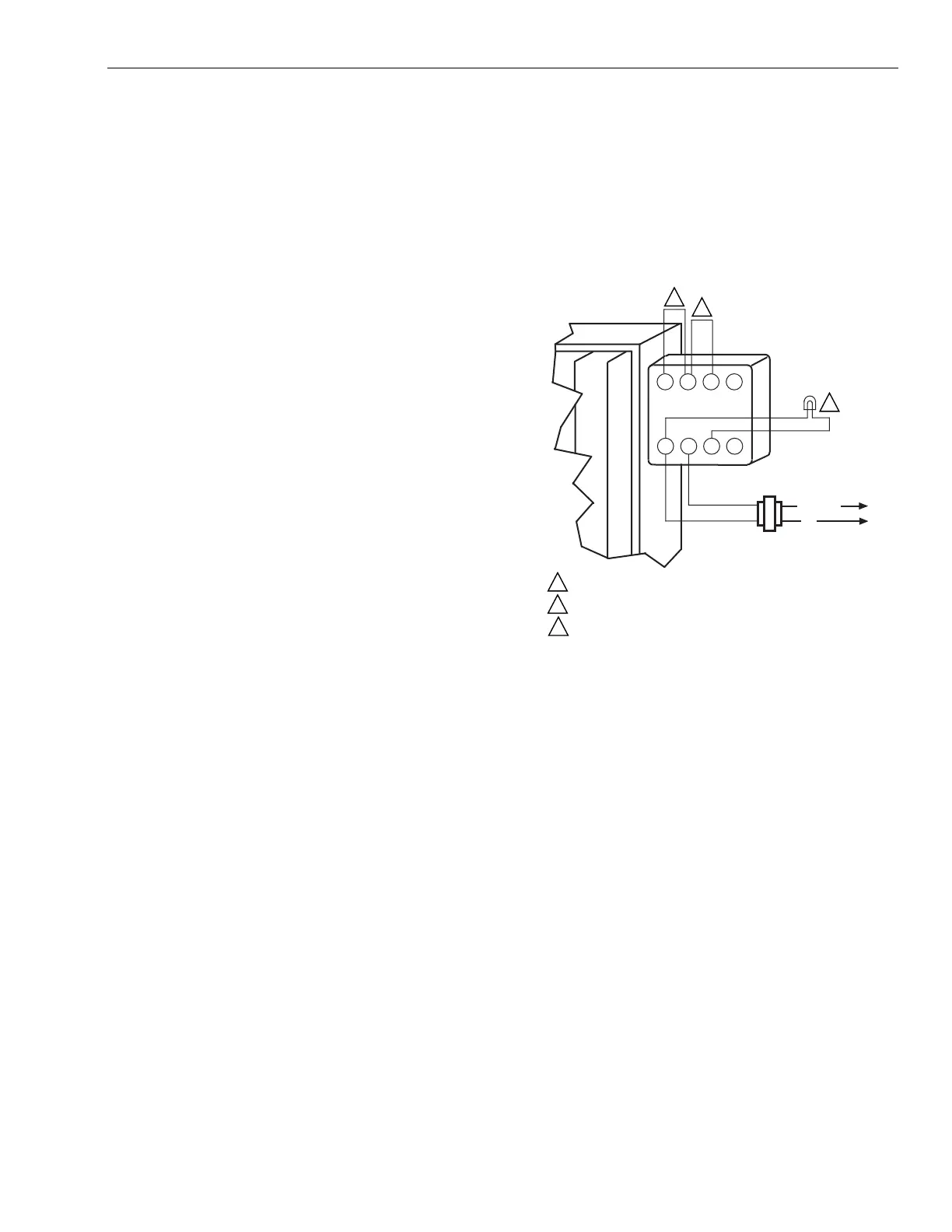

Checking Electric Actuator (See Fig. 16)

1.

Remove wires from the damper terminals.

2.

Connect 24 Vac to electric actuator terminals 1 and 2.

3.

Ensure the electric actuator operates correctl

:

a. Remove wires from terminals 4 and 6.

b. Short terminals 4 and 5 to open the damper blades.

c. Short terminals 5 and 6 to close the damper blades.

1

If the dampers open and close as indicated, the

s

stem is operational.

2

If the dampers do not operate, as indicated,

replace the electric actuator and repeat steps 1

and 2.

4.

Ensure the end-switch operates correctl

:

a. Connect a 24 Vac test li

ht between terminals 1 and

3.

b. Short terminals 4 and 5:

1

When the damper blades are full

open, the

end-switch en

a

es, the 24 Vac test li

ht turns

on, and the electric actuator turns off.

c. Short terminals 5 and 6:

1

When the damper blades are full

closed, the

end-switch en

a

es, the 24 Vac li

ht turns off,

and the electric actuator turns off.

5.

If the motor and end-switches do not operate, as indi-

cated, replace the electric actuator and repeat steps 1

throu

h 4.

6.

Replace the electric actuator enclosure.

Fig. 16. Checking the electric actuator.

Replacing Electric Actuator

IMPORTANT

Electric actuator is shipped in the open damper posi-

tion.

1.

Usin

a 1-16 Allen wrench, loosen the crank arm set-

screw that connects the crank arm to the motor drive

shaft.

2.

Remove the crank arm from the motor drive shaft.

3.

Remove the two screws from the crank arm side of the

actuator box.

4.

Remove the electric actuator from the actuator box.

5.

Install the new electric actuator into the actuator box.

6.

Ti

hten the two screws into the crank arm side of the

actuator box.

7.

Attach the crank arm to the motor drive shaft.

8.

Ti

hten the crank arm set screw.

4

56

z

1

2

3

x

L1 (HOT)

L2

24V

24V

TEST

LIGHT

SHORT TERMINALS 4 AND 5 TO OPEN DAMPER BLADES.

SHORT TERMINALS 5 AND 6 TO CLOSE DAMPER BLADES.

24V TEST LIGHT TURNS ON WHEN DAMPER BLADES OPEN

AND TURNS OFF WHEN DAMPER BLADES CLOSE.

M2278A

1

2

3

1

2

3

Loading...

Loading...