.J

high capacity 1 in. BSPP by 1 in. BSPP gas control.

THERMOCOUPLE REQUIRED (ordered separately) for

24V, 100V, 120V, and

2201240V

models: Q309 orQ340

suggested.

Nominal output: 30 mV, 0.02 ohms,

Open circuit turndown voltage: 2mV.

POWERPILE GENERATOR REQUIRED (order sepa-

rately) for 75o

mV

models: Q302 or Q313 suggested.

Nominal output: 750 mV, 3.4 ohms.

Open circuit turndown voltage: 141 mV.

OPTIONAL SPECIFICATIONS:

1. Inlet pressure tap, 1/8 in. NPT.

2. Side outlets.

REPLACEMENT PARTS:

1.392451-1 Energy Cutoff

(ECO)

Connector.

2. Valve Operators:

Powerpile Operator: VS824.

Modusnap

operator with modulating control: V5306.

3. Servo Gas Pressure Regulators.

Standard pressure regulator: V5306.

Step-opening pressure regulator: V5307.

WHEN INSTALLING THIS PRODUCT...

1.

Read these instructions carefully. Failure to follow

instructions can damage product or cause a hazardous

condition.

2. Check ratings given in instructions and on product to

make sure product is suitable for your application.

3. Make sure installer is a trained, experienced service

technician.

4. After completing installation, use these instructions to

check out product operation.

FIRE OR EXPLOSION HAZARD

CAN CAUSE PROPERTY DAMAGE, SEVERE

INJURY, OR DEATH

Follow these warnina

exactlv.

1.

2.

3.

4.

To avoid

dangero&

accumulation of

fuel gas,

turn off gas supply at appliance service valve

before starting installation and perform Gas

Leak Test after completion of installation.

Do not bend pilot tubing at the cantroi or piiot

after compression nut has been tightened.

Gas

ieakage at the connection may resuit.

Aiways

instaii

sediment trap in gas

suppiy

line to prevent contamination of gas

controi.

Do not force gas

controi

knob. Use oniy your

hand to turn gas

controi knob. Never use any

tools. if gas

controi knob wili not operate by

hand, the

controi

shouid

be

repiacsd

by a

quaiified

service technician. Force or at-

tempted repair may resuit in fire or expiosion.

1. Disconnect power supply before wiring to prevent

electrical shock or equipment damage.

2. Never apply a jumper across (or short) valve coil

terminals. This may burn out heat anticipator in

thermostat.

r

IMPORTANT

These gas controis are shipped with protective seals

over inlet and outiet tappings. Do not remove seals

until ready to connect piping.

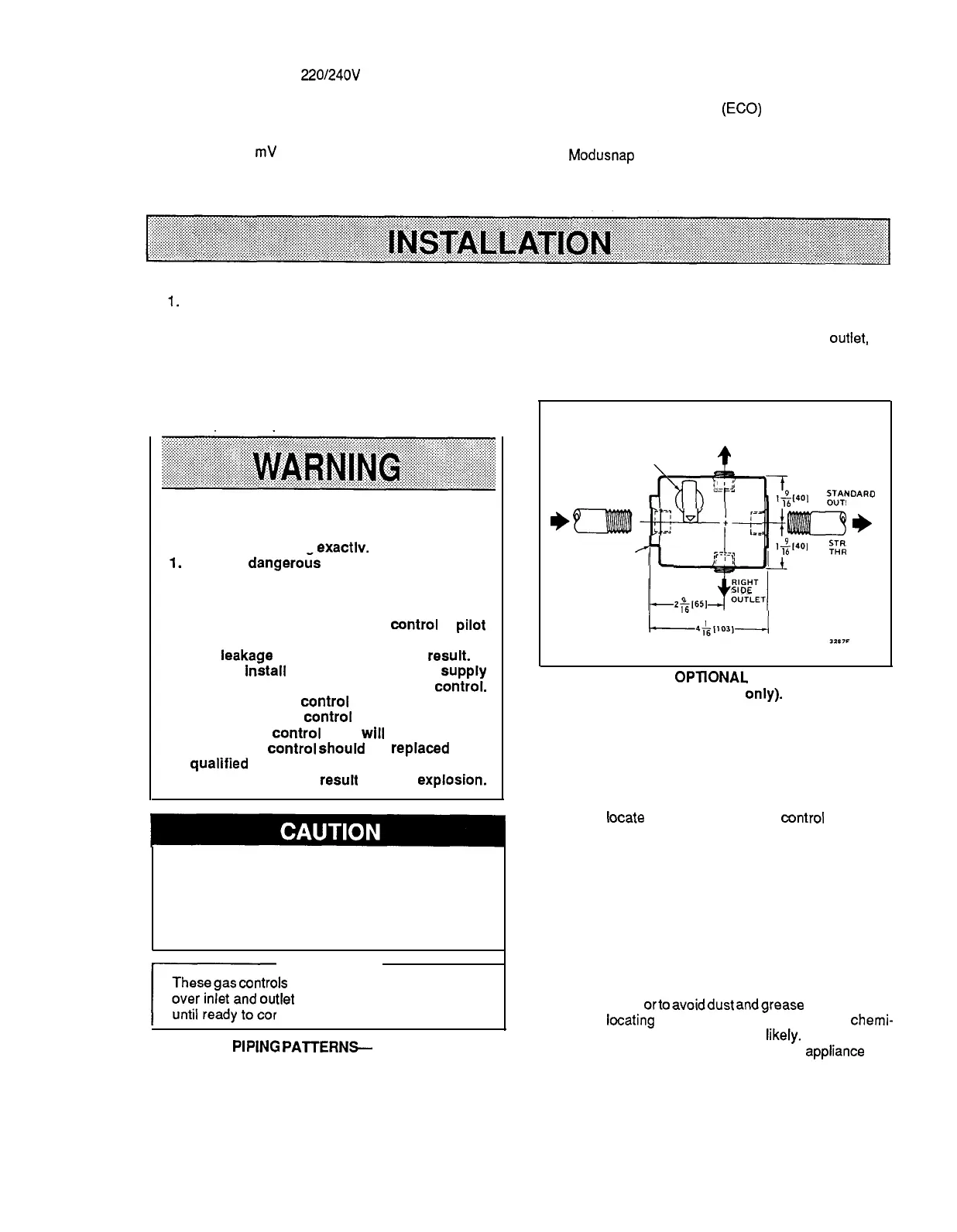

OPTiONAL

PiPiNG

PATTERNS-

TRADELiNE MODELS

To facilitate installation, TRADELINE models incorpo-

rate side outlets in the standard straight-through body.

Refer to Fig. 3.

To fit existing piping, reducer fittings also are included.

These controls are shipped with side outlets plugged as

shown. if connection is made to optional side

outiet,

be

sure to install plug in standard straight-through outlet

tapping. Use plug removed from side outlet.

Perform Gas Leak Test when installation is complete.

LEFT SIDE

OUTLET

MAN

UAL GAS

CONTROL KNoB \

+

9“

~=t

i

r

.

-T,

STANDARO

‘ii?401

OUTLET

•mq”+~

1

+

INLET

STRAIGHT

WRENCH

L

‘K[eol

THROUGH

BOSS

~=,

.1

h’

RIGHT

SIOE

9

OUTLET

%16$J

FiG. 3—TRADELiNE

OPllONAL

SiDE OUTLETS (stan-

dard capacity models

oniy).

Follow appliance manufacturer’s instructions if avail-

able; otherwise, use instructions provided below as a

guide.

LOCATiON

Do not

iocate

the combination gas controi where ad-

verse environments such as steam cleaning, high humidity

or dripping water, corrosive chemicals, dust or grease ac-

cumulation, or excessive heat are prevalent. To ensure

proper operation, follow these guidelines:

● Locate in a well ventilated area.

● Mount high enough above the cabinet bottom to

avoid exposure to flooding or splashing water.

● Ensure that the ambient temperature does not ex-

ceed the ambient temperature ratings for each

component.

● Cover if appliance is cleaned with water, steam, or

chemicals

ortoavoiddust

andgrease

accumulation.

● Avoid

iocating

where exposure to corrosive

chemi-

cai fumes or dripping water is

iikely.

Mount the combination gas control in the

appiiance ves-

tibule on the gas manifold. if this is a replacement applica-

tion, mount the control in same location as old control.

60-2019-7

Loading...

Loading...