WIRING

Follow wiring instructions furnished by appliance manu-

facturer, if available, or use general instructions provided

below. Where instructions differ, follow appliance

manufacturer’s instructions.

All wiring must comply with applicable electrical codes

and ordinances or with the National Electrical Code

(ANS1/

NFPA 70), whichever applies.

Disconnect power supply before making wiring connec-

tions to prevent electrical shock or equipment damage.

Wiring 24V Models

NOTE: The

V800

and V801 have a blue terminal block.

Terminals and markings are identical.

1. Make sure the power supply rating on each control

matches the available supply. Install transformer, low

voltage thermostat, and other controls as required.

2. Connect control circuit to operatorterminals. Refer to

Fig. 9 for typical 24V wiring diagram.

3. Adjust thermostat heat anticipator to 0.2A rating

stamped on valve operator.

,,,R:–~q_co.pLE

24 VOLT

HIGH LIMIT

THERMOSTAT

~.---

_-7

, CAUTION ,

CONTROLLER

A’

Iwl

I

-SEE 2

I

l~-i-l-

&

TRANSFORMER

,!+

—

,.

f!!!!

POWER SUPPLY PROVIDE DISCONNECT MEANS AND OVERLOAD PRO

TECTION

AS

REQUIRED.

~

NE”ER,”MPER

THESE

TERMINALS THIS

51+ORTSC3UT

“ALVE

COIL

AND

M4Y

BURN OUT HEAT ANTICIPATOR IN THERMOSTAT

~

ORDER

ECD

LIMIT

4ND

LE.4CIWIRES

SEPARATELY

2352.

FIG. 9—TYPICAL WIRING HOOKUP FOR 24V SYS-

TEMS.

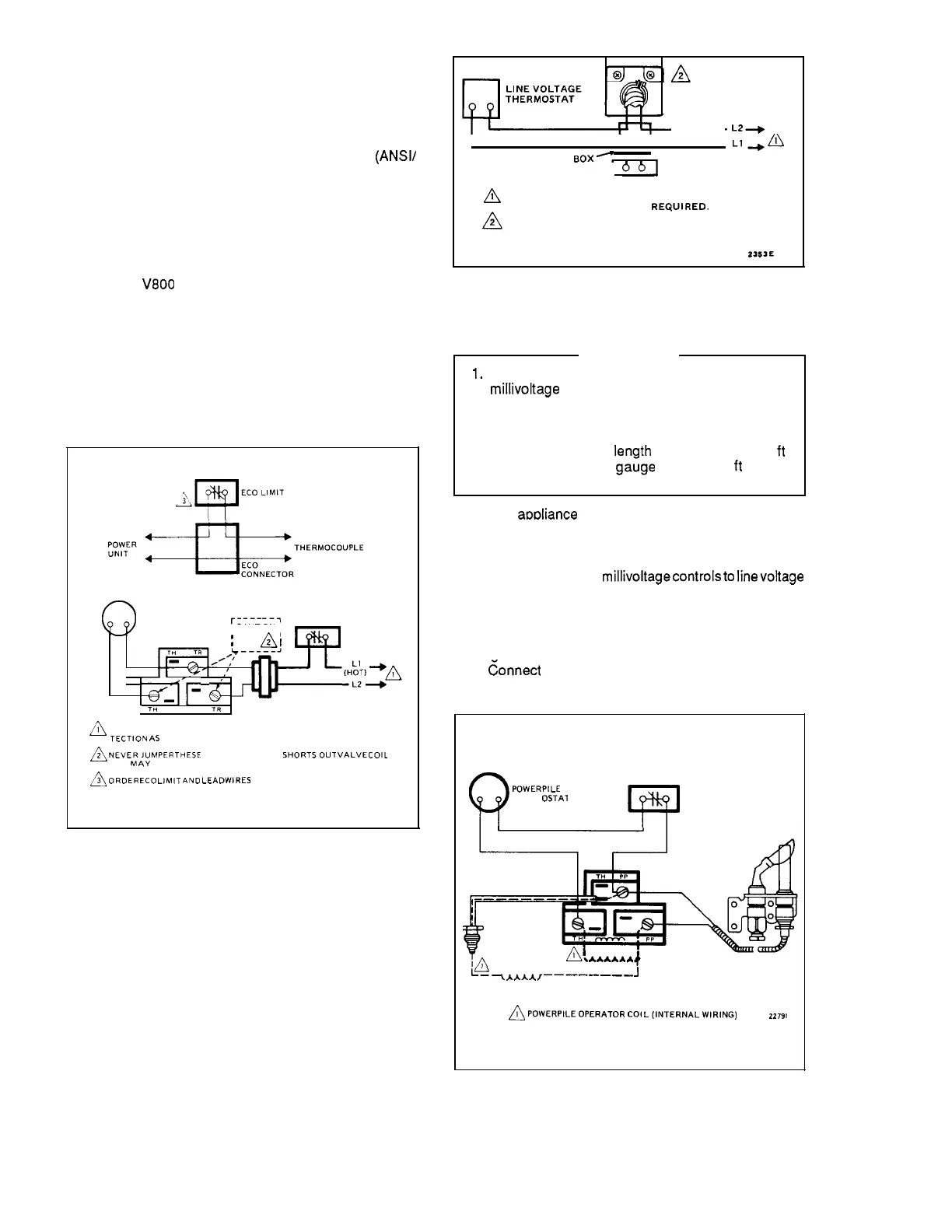

Wiring 110V, 120V, 220/240V Models

1. Make sure power supply rating on each control

matches available supply. Install line voltage thermostat

(or controller) and other controls as required. Refer to Fig.

10 for typical wiring diagram.

2. Use junction box, as shown, when connecting control

circuit to gas control operator. Make conduit connection to

operator as follows:

a. Slip conduit fittings over integral leadwires and

screw securely into hole in operator cover.

b. Cut flexible conduit to appropriate length. Slip

conduit over leadwires and attach to fittings.

c. Route and connect both flexible conduits to junc-

tion box. Connect integral wires to control circuit. Do

not splice except within a junction box.

LINE VOLTAGE

OPERATOR

OR CONTROLLER

L2+

.

I

I

1

Ll+~

1

JUNCTION

BOX-

,

,

db]

LIMIT

(HOT)

CONTROLLER

POWER SUPPLY. PROVIOE DISCONNECT MEANS ANO

OVERLOAD PROTECTION AS REQUIREO.

LINE VOLTAGE ENCLOSURE NOT PART OF GAS CON-

TROL. LINE VOLTAGE GAS CONTROLS MUST BE USED

IN AN OEM APPROVED ENCLOSURE.

2353E

FIG. 1O—TYPICAL WIRING HOOKUP FOR 120V SYS-

TEM.

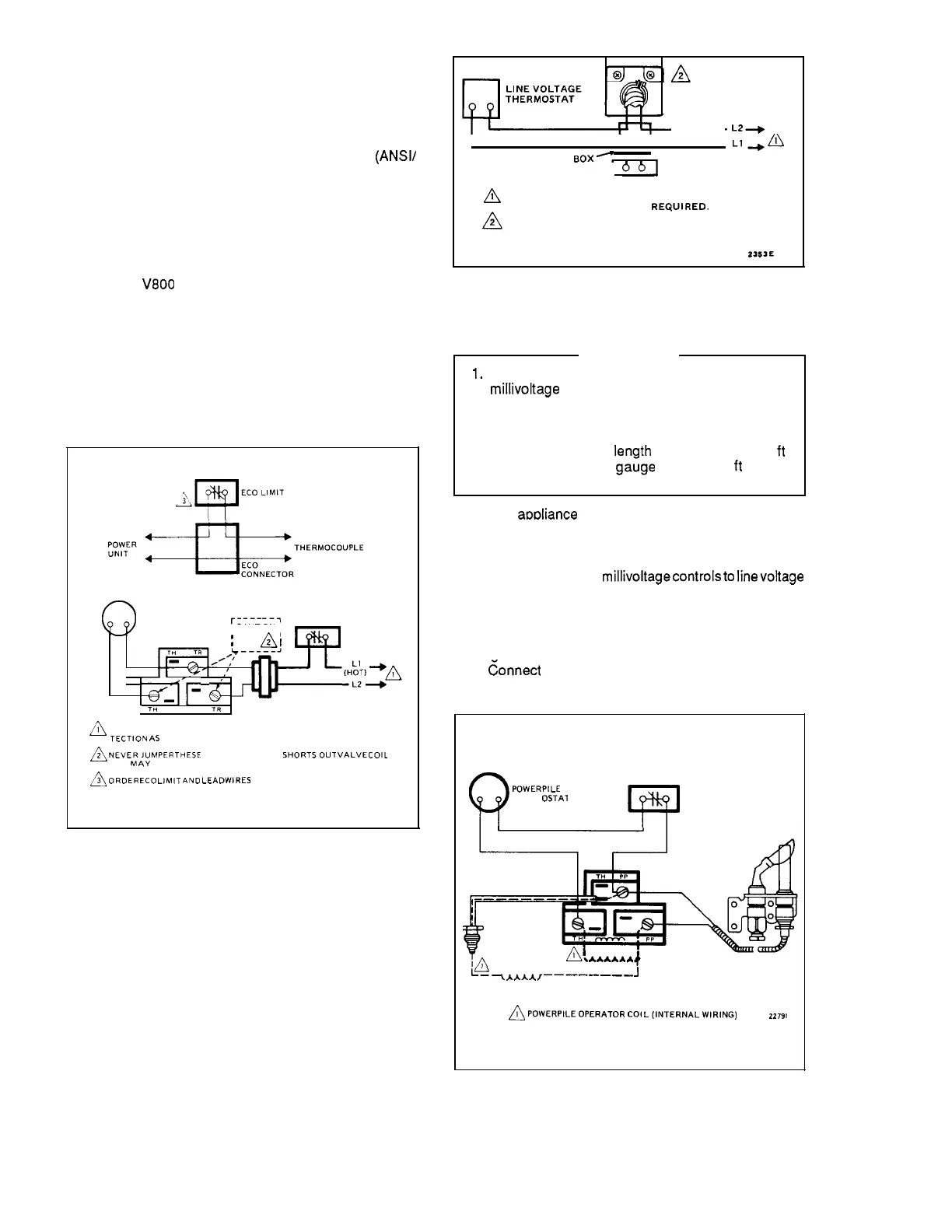

Wiring Powerpile Models

IMPORTANT

1.

2.

Since the entire control system is powered by the

millivoltage

generated by the Powerpile genera-

tor, clean and scrape all wires before connecting.

Solder and tape all necessary splices using rosin

flux to prevent corrosion.

Control circuit cable

Ienath

must not exceed 30

ft

[9 mm] of 2-wire, 18 ga~ge cable, or 50

ft

[15 m]

of 2-wire, 16 gauge cable.

Follow

aooliance

manufacturer’s wirina instructions. if

available, or’ use general instructions p-rovided below.

Where instructions differ, follow appliance manufacturer

instructions.

Never connect these

millivoltagecontrolsto

Iinevoltage

or to a transformer.

To prevent electrical shock or equipment damage, dis-

connect power supply before making wiring connections.

1. After Powerpile generator is installed in pilot burner,

route aenerator lead to aas control.

2. ~onnect lead tog& control terminals labeled PP.

3. Connect thermostat leads as shown in Fig. 11 or 12.

$?

PowERPILE

THERM

OSTA1

w

HIGH LIMIT

CONTROLLER

l.++

—

,AAAA,—————_——

J

POWER UNIT CONTROL

~

POWERPILEOPERATOR

CO,

L(INTERNALW,RING)

22791

,F-

FIG. 11—TYPICAL WIRING CONNECTIONS FOR GAS

CONTROL WITH THREE-TERMINAL OPERATOR.

8

Loading...

Loading...