VC SERIES

EN0H-0327GE25 R0206 6 Honeywell • All rights reserved

Installation

WARNING

Installer must be a trained, experienced service

person.

When installing this product:

• Read these instructions carefully. Failure to follow

them could damage the product or cause a hazardous

condition.

• Check the ratings given in the instructions and on the

product to make sure it is suitable for your

application.

• Always conduct a thorough checkout after installation.

CAUTION

• Disconnect power supply before wire connection to

prevent electrical shock and equipment damage.

• It is advisable to remove the actuator head from the

valve body for ease of installation. Fit the actuator

head in the most convenient position for wiring.

• On sweat fitted valves, the cartridge is shipped loose

or is removed to avoid being damaged during the sol-

der operation.

• On 24 V systems, never short circuit the valve coil

terminals. This may burn out the heat anticipator in

the thermostat.

• To remove the actuator head 25 mm clearance is

needed above the actuator.

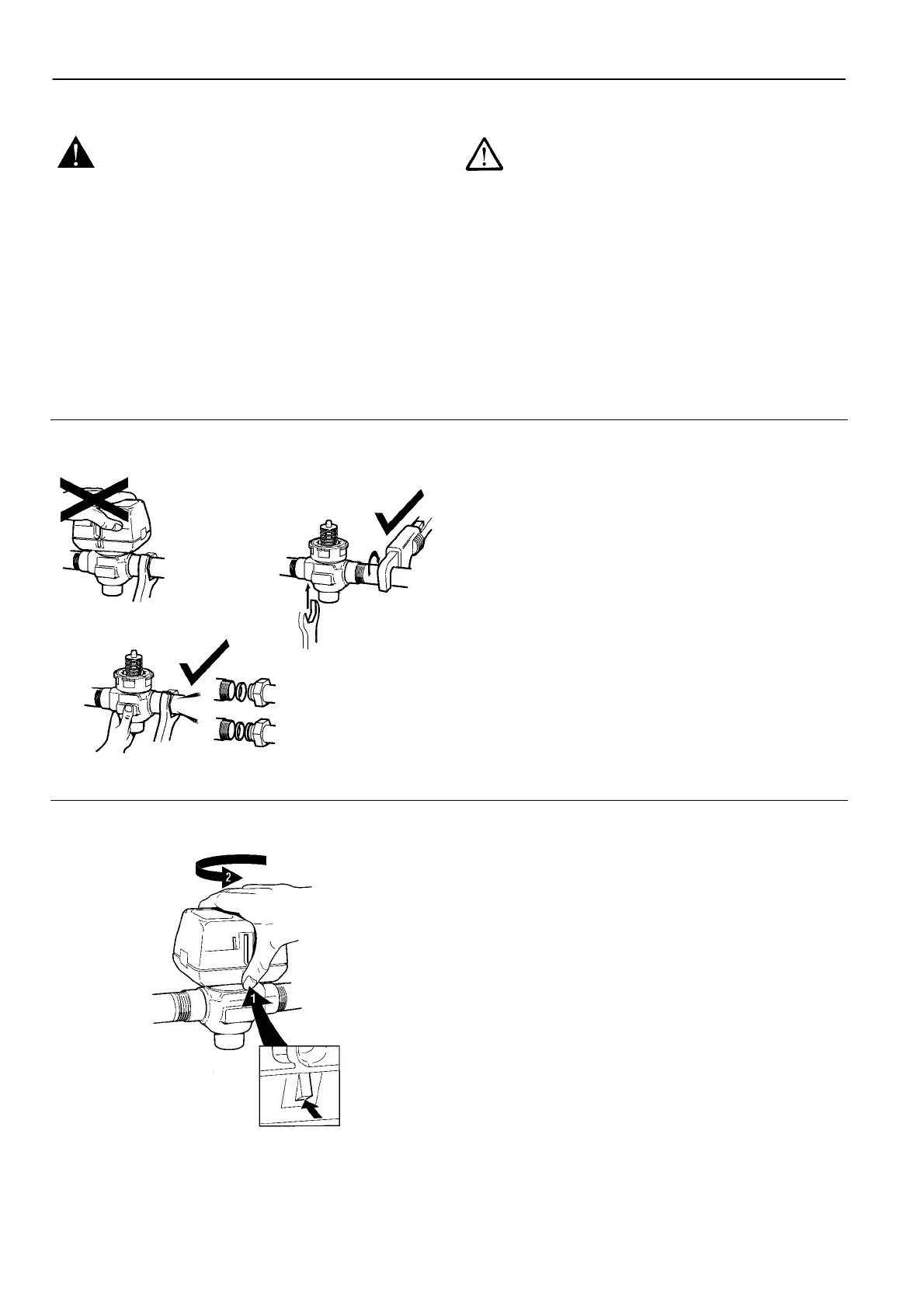

Plumbing

Fig. 7. Plumbing

The valve may be plumbed in any angle but preferably not

with the actuator head below the horizontal level of the valve

body. Make sure there is enough room around the actuator

head for servicing or replacement.

When used to form part of a central heating system, do not

locate it where it will block the system vent, cold feed or any

bypass when the valve is closed.

Mount the valve directly in the tube or pipe. Do not grip

actuator head while making and tightening plumbing

connections. Either hold valve body in your hand or attach

adjustable spanner across the hexagonal or flat faces on the

valve body.

Compression models

For compression fitted models, tighten the compression nuts

enough to make a watertight seal. Take care not to

overtighten.

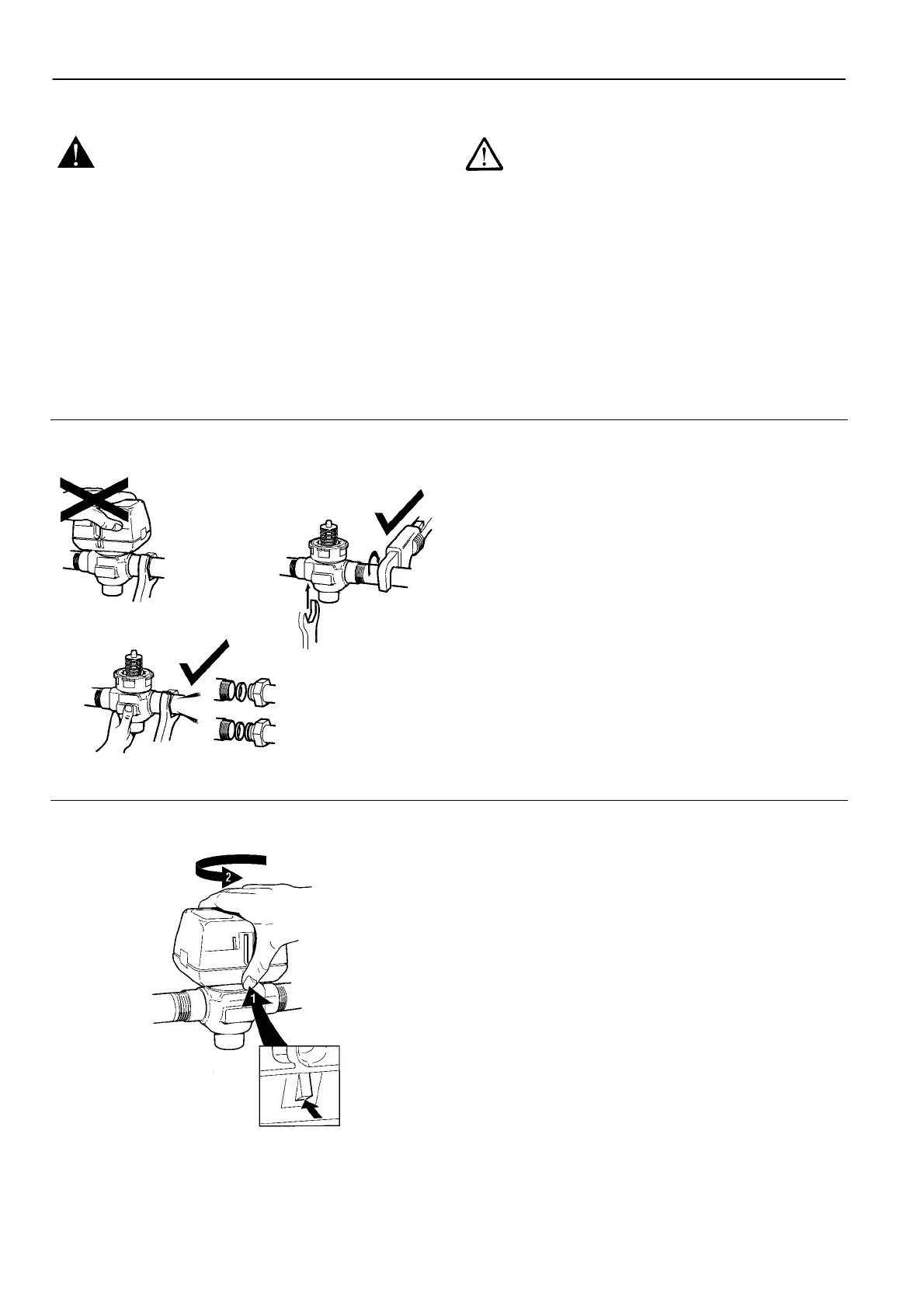

To install a replacement actuator head

Fig. 8. Latch mechanism

Important

Installation of a new actuator head does not require draining

the system providing the valve body and cartridge assembly

remain in the pipeline.

1. Disconnect power supply before servicing to avoid electri-

cal shock or equipment damage.

2. Disconnect leadwires to actuator head, or depress tab on

Molex™

connector and remove. Where appropriate, label

wires for rewiring.

3. The actuator head is automatically latched to valve (see

figure 8). To remove, lift up on the latch mechanism lo-

cated directly below the red manual open lever. Press the

actuator head down towards the body with moderate hand

force and turn counter-clockwise by 1/8 turn (45 degrees)

simultaneously. Lift the actuator head off the valve body.

NOTE: Actuator can also be installed at right angles to valve

body but in this position latch mechanism is not engaged.

4. Install the new actuator head by reversing process in (3).

5. Reconnect leadwires or Molex™

connector.

6. Restore power.

Loading...

Loading...